- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

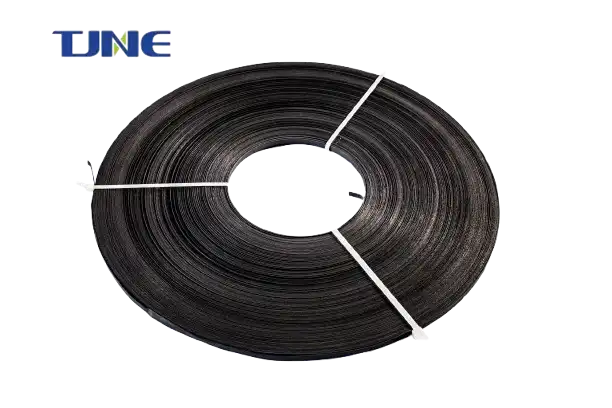

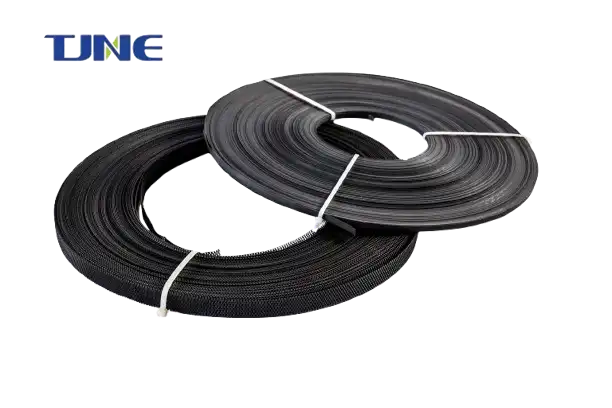

Mixed Metal Oxide (MMO) ribbon anodes are advanced cathodic protection devices used to prevent corrosion in various structures and systems. These anodes are made of a thin, flexible ribbon-like structure coated with a mixture of metal oxides, typically including titanium, ruthenium, and iridium. The unique design and composition of MMO ribbon anodes make them highly effective in distributing electrical current evenly across large surfaces, providing superior corrosion protection in challenging environments.

What are the advantages of using MMO ribbon anodes?

MMO ribbon anodes offer several significant advantages over traditional cathodic protection methods, making them an increasingly popular choice in various industries. Here are some key benefits:

1. Durability and longevity: MMO ribbon anodes are known for their exceptional durability and long service life. The mixed metal oxide coating is highly resistant to wear and degradation, allowing these anodes to operate effectively for extended periods, often exceeding 20 years in many applications. This longevity translates to reduced maintenance costs and fewer system interruptions over time.

2. Flexibility and versatility: The ribbon-like structure of MMO anodes provides excellent flexibility, allowing them to conform to various shapes and surfaces. This adaptability makes them ideal for use in complex geometries and confined spaces where traditional rigid anodes may be challenging to install. MMO ribbon anodes can be easily wrapped around pipelines, integrated into concrete structures, or installed in soil and water environments.

3. Uniform current distribution: One of the most significant advantages of MMO ribbon anodes is their ability to distribute electrical current evenly across large surfaces. The ribbon design ensures a more uniform protection of the structure, reducing the risk of localized corrosion and hot spots. This feature is particularly beneficial in applications where consistent protection is crucial, such as in large-scale infrastructure projects or offshore installations.

4. Low resistance: MMO ribbon anodes typically have a lower resistance compared to other anode types, which results in improved current output and more efficient cathodic protection. This lower resistance allows for better current flow, ensuring that the protected structure receives adequate protection even in high-resistivity environments.

5. Lightweight and easy installation: The lightweight nature of MMO ribbon anodes simplifies transportation and installation processes. Their flexibility allows for easier handling and positioning, reducing installation time and costs. This is especially advantageous in retrofit projects or applications where access is limited.

6. Environmental friendliness: MMO ribbon anodes are considered more environmentally friendly compared to some traditional anode materials. They do not release harmful substances into the surrounding environment during operation, making them suitable for use in sensitive ecological areas or applications where environmental impact is a concern.

7. Customizability: MMO ribbon anodes can be customized in terms of length, width, and coating composition to suit specific project requirements. This adaptability allows engineers to design cathodic protection systems that are tailored to the unique needs of each application, optimizing performance and efficiency.

These advantages make MMO ribbon anodes an attractive option for a wide range of cathodic protection applications, from pipeline protection and reinforced concrete structures to marine installations and underground storage tanks.

How do MMO ribbon anodes compare to other types of anodes?

When comparing MMO ribbon anodes to other types of anodes used in cathodic protection systems, several factors come into play. Let's examine how MMO ribbon anodes stack up against some common alternatives:

1. MMO ribbon anodes vs. Galvanic anodes:

Galvanic anodes, such as zinc, magnesium, or aluminum anodes, operate on the principle of sacrificial protection. While they are simple to install and do not require an external power source, they have a limited lifespan and must be replaced periodically. In contrast, MMO ribbon anodes:

- Have a much longer service life, often lasting 20+ years

- Provide more consistent and controllable current output

- Are more suitable for high-resistivity environments

- Offer better current distribution over large areas

However, galvanic anodes may be preferable in situations where power sources are unavailable or for small, localized protection needs.

2. MMO ribbon anodes vs. High Silicon Cast Iron (HSCI) anodes:

HSCI anodes are known for their durability and have been widely used in impressed current cathodic protection systems. Compared to HSCI anodes, MMO ribbon anodes offer:

- Greater flexibility and ease of installation

- More uniform current distribution

- Lower weight, making transportation and handling easier

- Better performance in high-resistivity environments

HSCI anodes may still be preferred in some deep well applications or where extremely high current outputs are required.

3. MMO ribbon anodes vs. Platinized titanium anodes:

Platinized titanium anodes are another type of dimensionally stable anode used in cathodic protection. MMO ribbon anodes compare favorably in several aspects:

- Generally lower cost due to the use of mixed metal oxides instead of platinum

- Longer service life in most applications

- Better current distribution due to the ribbon design

- More flexible and adaptable to various geometries

However, platinized titanium anodes may still be chosen for specific applications where their unique properties are advantageous.

4. MMO ribbon anodes vs. Graphite anodes:

Graphite anodes have been used in cathodic protection for many years due to their low cost and availability. MMO ribbon anodes offer several advantages over graphite:

- Significantly longer service life

- Lower consumption rate, resulting in less environmental impact

- Better current distribution and efficiency

- Greater mechanical strength and resistance to breakage

Graphite anodes may still be used in some applications where initial cost is a primary concern, but MMO ribbon anodes generally offer better long-term value.

5. MMO ribbon anodes vs. Conductive polymer anodes:

Conductive polymer anodes are a relatively new technology in cathodic protection. While they offer some similar benefits to MMO ribbon anodes, such as flexibility and ease of installation, MMO ribbon anodes generally provide:

- Longer service life

- Higher current output capabilities

- Better performance in high-temperature environments

- More extensive track record and proven reliability

When selecting the most appropriate anode for a cathodic protection system, factors such as the environment, structure geometry, required current output, system lifespan, and installation constraints must be considered. MMO ribbon anodes excel in many of these areas, making them a versatile and effective choice for a wide range of applications.

Their ability to provide uniform current distribution, long service life, and adaptability to various installation scenarios has led to their increasing adoption in industries such as oil and gas, infrastructure protection, and marine applications. However, it's important to note that each project may have unique requirements, and a thorough analysis should be conducted to determine the most suitable anode type for specific applications.

What are the common applications of MMO ribbon anodes?

MMO ribbon anodes have found widespread use in various industries due to their versatility, efficiency, and durability. Here are some of the most common applications where these anodes play a crucial role in corrosion protection:

1. Pipeline Protection:

One of the primary applications of MMO ribbon anodes is in the protection of underground and subsea pipelines. These anodes are particularly effective for:

- Long-distance oil and gas pipelines

- Water transmission lines

- Sewage pipelines

- Chemical transport pipelines

The flexibility of MMO ribbon anodes allows them to be installed along the length of the pipeline, providing uniform protection even in areas with complex soil conditions or varying resistivity. They can be buried directly in the soil or installed in shallow groundbeds parallel to the pipeline, ensuring comprehensive corrosion protection.

2. Reinforced Concrete Structures:

MMO ribbon anodes have become increasingly popular in protecting reinforced concrete structures from corrosion. They are used in:

- Bridges and overpasses

- Parking garages

- Marine piers and jetties

- Concrete buildings in corrosive environments

In these applications, the ribbon anodes can be embedded within the concrete during construction or applied to the surface as part of a rehabilitation project. Their ability to distribute current evenly helps prevent reinforcement corrosion, extending the life of the structure and reducing maintenance costs.

3. Marine and Offshore Structures:

The corrosive nature of seawater makes marine and offshore applications particularly challenging. MMO ribbon anodes are well-suited for protecting:

- Offshore oil and gas platforms

- Ship hulls and ballast tanks

- Port facilities and dock structures

- Underwater pipelines and cables

Their resistance to chloride environments and ability to operate effectively in seawater make them an excellent choice for these demanding applications. The ribbon design allows for easy installation on complex geometries often found in marine structures.

4. Storage Tanks:

Both above-ground and underground storage tanks benefit from the protection offered by MMO ribbon anodes. They are commonly used in:

- Fuel storage tanks

- Water storage tanks

- Chemical storage facilities

- Oil and gas tank farms

For underground tanks, the anodes can be installed in the backfill material surrounding the tank. In above-ground applications, they can be placed in a ring around the tank's base or in vertical groundbeds nearby.

5. Industrial Facilities:

Various industrial facilities utilize MMO ribbon anodes to protect critical infrastructure, including:

- Chemical processing plants

- Refineries

- Power generation facilities

- Wastewater treatment plants

In these settings, the anodes can be used to protect a wide range of structures, from buried piping networks to large-scale equipment foundations.

6. Utility Networks:

Utility companies often employ MMO ribbon anodes to protect their extensive networks of underground assets, such as:

- Electrical grounding systems

- Telecommunication cables

- Gas distribution networks

- District heating systems

The ability to install long lengths of ribbon anode makes them ideal for protecting these linear structures that often span great distances.

7. Architectural Elements:

In some cases, MMO ribbon anodes are used to protect architectural elements exposed to corrosive environments, including:

- Metal cladding on buildings

- Decorative metal structures

- Sculptures and monuments

- Roofing systems

Their flexibility allows for discreet installation that doesn't compromise the aesthetic appeal of these structures.

8. Transportation Infrastructure:

Beyond bridges, MMO ribbon anodes are used in other transportation-related applications, such as:

- Airport runways and taxiways

- Railway tracks and supporting structures

- Highway sound barriers

- Tunnel linings

The durability and long service life of these anodes make them well-suited for critical infrastructure that requires consistent, long-term protection.

9. Renewable Energy Structures:

As the renewable energy sector grows, MMO ribbon anodes are finding applications in protecting:

- Offshore wind turbine foundations

- Wave and tidal energy devices

- Solar panel support structures in corrosive environments

- Geothermal well casings

These applications often involve challenging environmental conditions where the performance advantages of MMO ribbon anodes are particularly beneficial.

10. Archaeological Preservation:

In some specialized cases, MMO ribbon anodes have been used in the preservation of archaeological sites and artifacts, particularly those exposed to marine environments or buried in corrosive soils.

The wide range of applications for MMO ribbon anodes demonstrates their versatility and effectiveness in combating corrosion across various industries and environments. As corrosion continues to be a significant concern in many sectors, the use of these advanced anodes is likely to expand further, driven by their proven performance, long service life, and ability to protect complex structures efficiently.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References

1. NACE International. (2021). Cathodic Protection - An Overview.

2. Baeckmann, W. V., Schwenk, W., & Prinz, W. (1997). Handbook of Cathodic Corrosion Protection. Gulf Professional Publishing.

3. Revie, R. W., & Uhlig, H. H. (2008). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. John Wiley & Sons.

4. DNV GL. (2017). Cathodic Protection Design. Recommended Practice DNVGL-RP-B401.

5. Bushman, J. B. (2001). Galvanic Anode Cathodic Protection System Design. NACE International.

6. Roberge, P. R. (2008). Corrosion Engineering: Principles and Practice. McGraw-Hill Education.

7. Cicek, V. (2014). Cathodic Protection: Industrial Solutions for Protecting Against Corrosion. John Wiley & Sons.

8. NACE International. (2013). Control of External Corrosion on Underground or Submerged Metallic Piping Systems. NACE SP0169-2013.

9. Tanner, R. (2016). Impressed Current Cathodic Protection System Design. NACE International.

10. Marcus, P. (2011). Corrosion Mechanisms in Theory and Practice. CRC Press.

Related Industry Knowledge

- In What Environments Can MMO Ribbon Anodes Be Effectively Used?

- What is an MMO Ribbon Anode?

- What is the Composition of MMO Ribbon Anodes?

- What is MMO Ribbon Anode?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- What is the Lifespan of MMO Ribbon Anodes?