- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

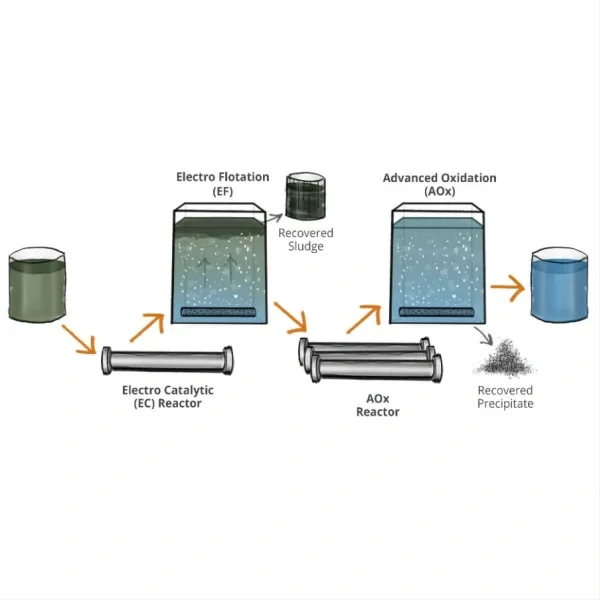

High Corrosion Resistance and Longevity: MMO tubular titanium anodes exhibit superior corrosion resistance compared to conventional anode materials, ensuring extended service life even in aggressive chemical environments. The mixed metal oxide coating provides a protective barrier that prevents corrosion and degradation, enabling long-term performance in challenging electrochemical applications.

Enhanced Electrochemical Activity: The electrocatalytic properties of MMO tubular titanium anodes promote efficient electrode reactions and electrolysis processes, leading to improved current distribution, higher current density, and enhanced overall performance. This enhanced electrochemical activity results in greater process efficiency, reduced energy consumption, and higher production yields in various electrochemical applications.

Dimensional Stability and Mechanical Strength: The tubular design of titanium anodes enhances their dimensional stability and mechanical strength, allowing them to withstand high current densities, temperature fluctuations, and mechanical stress without deformation or performance degradation. This structural integrity ensures reliable and consistent operation in demanding electrochemical environments.

Uniform Current Distribution: MMO tubular titanium anodes are engineered to provide uniform current distribution along their surface, minimizing localized effects such as pitting, scaling, or uneven plating in electrochemical processes. This uniformity enhances the quality and consistency of electrochemical reactions, ensuring precise control and optimized outcomes in diverse applications.

Versatility and Customization: With a wide range of sizes, shapes, coatings, and configurations available, MMO tubular titanium anodes offer versatility and customization to suit specific electrochemical requirements. Whether used in electroplating baths, water electrolysis cells, or industrial electrolytic cells, these anodes can be tailored to meet the unique demands of various applications, ensuring optimal performance and compatibility.

Environmental Sustainability: The use of MMO tubular titanium anodes promotes environmental sustainability by reducing the consumption of chemicals, energy, and resources in electrochemical processes. Their efficiency, durability, and recyclability contribute to lower operating costs, minimal waste generation, and overall eco-friendly practices in industrial applications.

Wide Range of Applications: MMO tubular titanium anodes find applications in diverse industries, including electroplating, metal recovery, water treatment, cathodic protection, electrowinning, and electrolytic production. Their adaptability to different electrolytes, pH levels, temperatures, and operating conditions makes them a versatile and reliable choice for a variety of electrochemical processes.

Cathodic protection is a vital technique used to prevent corrosion in metal structures by making them the cathode of an electrochemical cell. MMO Tubular Titanium Anodes play a pivotal role in this process by supplying the necessary current to counteract the corrosion reactions occurring on the protected metal surface. Unlike traditional sacrificial anodes, which are consumed during the protection process, MMO Tubular Titanium Anodes offer long-term durability and efficiency, making them a preferred choice in the industry.

One of the key features that set MMO Tubular Titanium Anodes apart is their superior durability. Made from high-quality titanium substrate coated with mixed metal oxides (MMO), these anodes exhibit excellent resistance to corrosion and degradation, even in harsh environments such as seawater or acidic soils. This durability ensures prolonged service life and minimal maintenance requirements, resulting in cost savings for asset owners.

Furthermore, MMO Tubular Titanium Anodes are highly efficient in delivering cathodic protection. Their unique design allows for uniform current distribution, ensuring comprehensive coverage of the protected structure and maximizing corrosion inhibition. This efficiency is essential for maintaining the integrity of critical infrastructure such as pipelines, storage tanks, and offshore platforms, where even minor corrosion can lead to catastrophic failures.

Where exactly can MMO Tubular Titanium Anodes be applied for maximum impact?

The versatility of these anodes makes them suitable for a wide range of applications, including marine structures, underground pipelines, industrial equipment, and reinforced concrete structures. By effectively mitigating corrosion in these assets, MMO Tubular Titanium Anodes contribute to the safety, reliability, and longevity of infrastructure systems essential for modern society.

Installation and maintenance are crucial aspects of cathodic protection systems, and MMO Tubular Titanium Anodes offer valuable insights in this regard. Proper installation, including correct positioning and electrical connection, is essential to ensure optimal performance of the anodes. Additionally, regular inspection and monitoring are necessary to detect any issues promptly and address them before they escalate. Fortunately, the robust design of MMO Tubular Titanium Anodes minimizes the need for frequent maintenance, simplifying the operation of cathodic protection systems.

Conclusion

In conclusion, MMO Tubular Titanium Anodes represent a revolutionary choice for electrochemical applications, particularly in cathodic protection. Their durability, efficiency, and versatility make them indispensable assets in safeguarding critical infrastructure against corrosion. As we continue to advance in materials science and engineering, MMO Tubular Titanium Anodes will undoubtedly play a significant role in ensuring the reliability and sustainability of modern society.

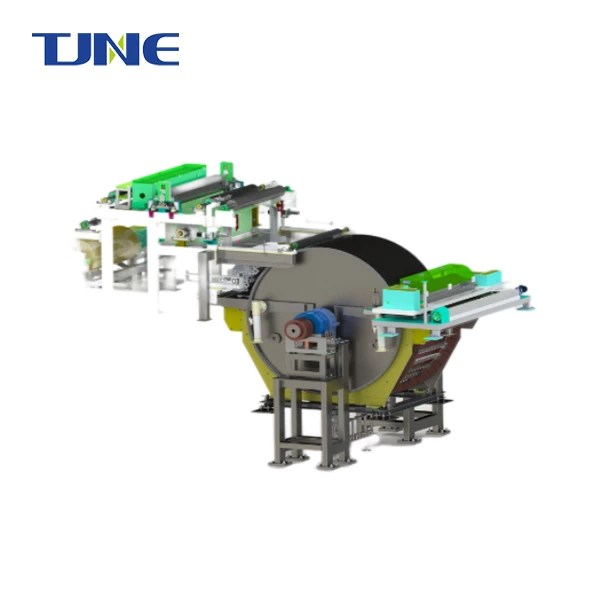

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about MMO Tubular Titanium Anodes, welcome to contact us: yangbo@tjanode.com.

References

1. Bard, A. J., & Faulkner, L. R. (2001). Electrochemical Methods: Fundamentals and Applications (2nd ed.). Wiley.

2. Postlethwaite, J., & Diamond, S. (2006). Cathodic Protection: Industrial Solutions for Protecting Against Corrosion. NACE International.

3. Roberge, P. R. (2008). Handbook of Corrosion Engineering (2nd ed.). McGraw-Hill Education.

4. Uhlig, H. H., & Revie, R. W. (1985). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. Wiley.

YOU MAY LIKE

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- The Power of Splitting Water: An In-Depth Look at Alkaline Water Electrolyzers

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- How Can an Electrodeposited Titanium Electrode Improve Nickel-Cobalt Battery Performance?

- Purifying the Seas: The Role of Titanium Electrodes in Ballast Water Treatment

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What are DSA anodes?