- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

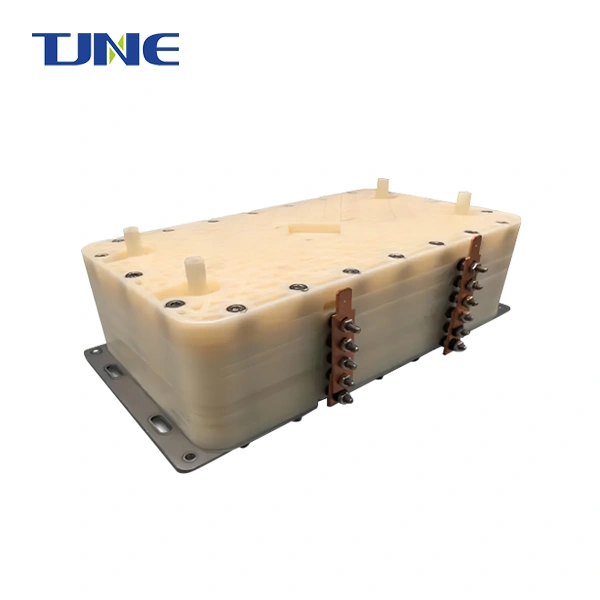

Seawater Electrolysis

2.Coating: Coated with ruthenium and iridium, ruthenium- iridium- platinum coatings. The chlorination potential is less than and equal to 1.1V.

3.Coating thickness: 0.2-20μm, maintaining stable operation in seawater electrolysis. Chlorine precipitation anode life >5 years, cathode life >20 years.

4.Working temperature: 5-40°C

The entry of aquatic invasive organisms into nonlocal waters through ballast water is a serious challenge for the entire maritime industry. TJNE ballast water treatment technology provides reliable treatment solutions for new and modified ships, which can comply with the strictest ballast water regulations in the world. The titanium electrode for seawater electrolysis plays a crucial role in the process of treating ballast water, which is essential for preventing the spread of harmful aquatic organisms and pathogens across different marine environments. In ballast water treatment systems, this electrode facilitates the electrolysis process, where an electrical current is applied to seawater, resulting in the generation of chlorine and other reactive species. These compounds are highly effective at disinfecting the water by killing or inactivating a wide range of microorganisms, including bacteria, viruses, and invasive species that could disrupt local ecosystems.

The exceptional corrosion resistance and durability of titanium ensure that the electrode maintains its performance over time, providing reliable operation in demanding conditions. Furthermore, titanium electrodes for seawater electrolysis can support high current densities, which enhances the efficiency of the electrolysis process, leading to quicker and more effective treatment of ballast water.

Titanium electrode for seawater electrolysis is constructed using advanced manufacturing techniques to ensure high efficiency and durability. Its key characteristics and features include:

High disinfection efficiency, ensuring compliance with ballast water treatment regulations

Optimized electrode design for reliable and efficient electrochemical reactions

Corrosion-resistant titanium material for durable and long-lasting performance

Easy installation and maintenance

Compact size and lightweight, saving space

| Item | Parameter |

|---|---|

| Substrate shape | Plate, mesh |

| Substrate thickness | 1mm, 2mm |

| Substrate | GR1, GR2 |

| Coating | Ru-Ir, Ru-Ir-Pt |

| Coating thickness | 0.2-20μm |

| Chlorine potential | ≤1.1V |

| Polarizability | ≤25mv |

| Working temperature | 5-40 °C |

Working Principle

Titanium electrode for seawater electrolysis utilizes electrochemical reactions to effectively treat ballast water. It generates chlorine and other oxidizing chemicals, which have strong disinfection properties, when an electric current is applied. These chemicals actively kill or remove harmful bacteria, microorganisms, and other pathogens present in the ballast water, ensuring the ballast water is clean and safe before discharge.

Structure

Titanium electrode for seawater electrolysis is specifically designed for use in ballast water treatment systems on marine vessels. Made of grade 1 titanium, it provides excellent corrosion resistance in seawater environments. The electrode consists of two main components - the titanium substrate and the mixed metal oxide coating.

The titanium substrate has a mesh-like structure that maximizes surface area. It is made by sintering high-purity titanium powder into a porous network. The high surface area allows for efficient electrochemical reactions during electrolysis of seawater. The mesh structure also allows for low flow resistance as water passes through the electrode.

On top of the titanium substrate, a thin coating of mixed metal oxide is applied using thermal decomposition. This coating is a proprietary blend optimized for chlorine generation. It typically contains oxides of ruthenium, iridium, tin, and other electrocatalysts. The coating significantly lowers overpotential and improves activation kinetics for the electrolytic reactions, resulting in efficient chlorine generation at low voltages.

FAQ

1. Is the titanium electrode suitable for all types of ballast water treatment systems?

Yes, the titanium electrode can be integrated into different types of ballast water treatment systems.

2. What is the lifespan of the titanium electrode?

The titanium electrode has a lifespan of 10 to 15 years, depending on the operating conditions and maintenance.

3. Are there any specific maintenance requirements for the titanium electrode?

The titanium electrode requires periodic cleaning and inspection to remove any potential fouling or scaling.

4. Does the titanium electrode meet international standards and regulations?

Yes, the titanium electrode complies with relevant international standards and regulations for ballast water treatment.

Contact Us

If you are considering selecting your own Titanium Electrode, please feel free to contact us at yangbo@tjanode.com.

TJNE is a professional manufacturer and supplier of titanium electrodes for seawater electrolysis, offering strong technical expertise, comprehensive after-sales service, complete certification and testing reports, fast delivery, and secure packaging. We fully support product testing and evaluation before purchase.