- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

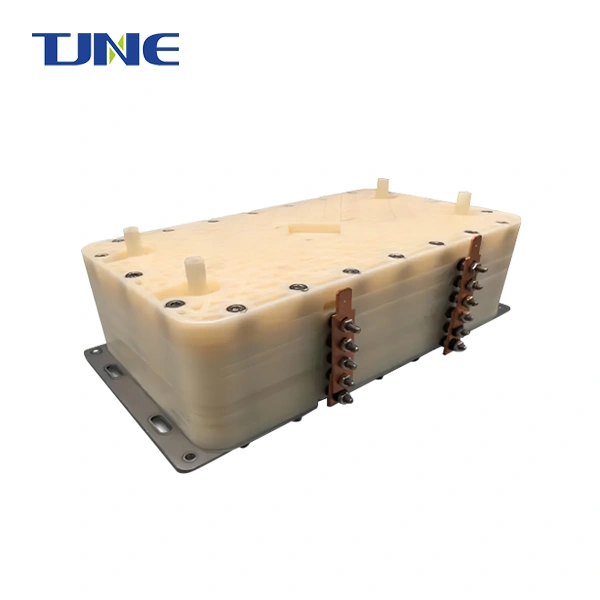

MMO Ribbon Anode is a specialized type of anode used in cathodic protection systems. It stands for Mixed Metal Oxide Ribbon Anode, which is a thin, flexible ribbon made of titanium substrate coated with a mixture of precious metal oxides. This innovative design allows for efficient and long-lasting corrosion protection in various applications, particularly in the oil and gas industry, marine environments, and infrastructure protection.

How does MMO Ribbon Anode work in cathodic protection systems?

Cathodic protection is a technique used to prevent corrosion of metal structures by making them the cathode of an electrochemical cell. MMO Ribbon Anodes play a crucial role in this process by serving as the anode in the system. Here's how they work:

1. Electrochemical reaction: When an electrical current is applied to the MMO Ribbon Anode, it initiates an electrochemical reaction. The anode releases electrons into the surrounding electrolyte (usually soil or water), while the metal structure being protected receives these electrons.

2. Polarization: As the protected structure receives electrons, its electrical potential becomes more negative. This process is called polarization, which effectively shifts the structure into a state where corrosion is thermodynamically unfavorable.

3. Oxide layer formation: The flow of electrons from the anode to the cathode (protected structure) causes the formation of a protective oxide layer on the surface of the metal. This layer acts as a barrier, further preventing corrosion.

4. Sacrificial protection: In addition to providing impressed current, the MMO Ribbon Anode itself undergoes a controlled form of corrosion, sacrificing itself to protect the target structure. However, due to its specialized composition, it corrodes at a much slower rate than traditional anodes.

5. Uniform distribution: The ribbon-like shape of MMO anodes allows for a more uniform distribution of current along the protected structure. This ensures that all areas receive adequate protection, even in complex geometries or long pipelines.

6. Longevity: The mixed metal oxide coating on the titanium substrate is highly resistant to wear and degradation. This results in a significantly longer lifespan compared to traditional anodes, often lasting 20 years or more in many applications.

7. Versatility: MMO Ribbon Anodes can be easily installed in various configurations, including direct burial in soil, concrete embedment, or submersion in water. This versatility makes them suitable for a wide range of applications, from pipelines to marine structures.

8. Monitoring and control: Modern cathodic protection systems using MMO Ribbon Anodes often incorporate sophisticated monitoring and control equipment. This allows for real-time adjustment of current output to maintain optimal protection levels and extend the anode's lifespan.

The efficiency and reliability of MMO Ribbon Anodes in cathodic protection systems have made them increasingly popular in industries where corrosion prevention is critical. Their ability to provide long-lasting protection with minimal maintenance has resulted in significant cost savings and improved safety in many infrastructure projects worldwide.

What are the advantages of using MMO Ribbon Anodes over traditional anodes?

MMO Ribbon Anodes offer several significant advantages over traditional anodes in cathodic protection systems. These benefits have contributed to their growing popularity and widespread adoption across various industries. Let's explore the key advantages in detail:

1. Longevity: One of the most significant advantages of MMO Ribbon Anodes is their exceptional lifespan. While traditional anodes may need replacement every few years, MMO anodes can last 20 years or more in many applications. This longevity is due to the stable mixed metal oxide coating on the titanium substrate, which resists wear and degradation even in harsh environments.

2. Higher current output: MMO Ribbon Anodes can deliver a higher current output per unit area compared to traditional anodes. This means that a smaller amount of MMO anode material can provide the same level of protection as a larger amount of conventional anode material. This higher efficiency translates to reduced installation costs and space requirements.

3. Uniform current distribution: The ribbon-like shape of MMO anodes allows for a more uniform distribution of current along the protected structure. This is particularly beneficial for long structures like pipelines or complex geometries where traditional point anodes might struggle to provide consistent protection.

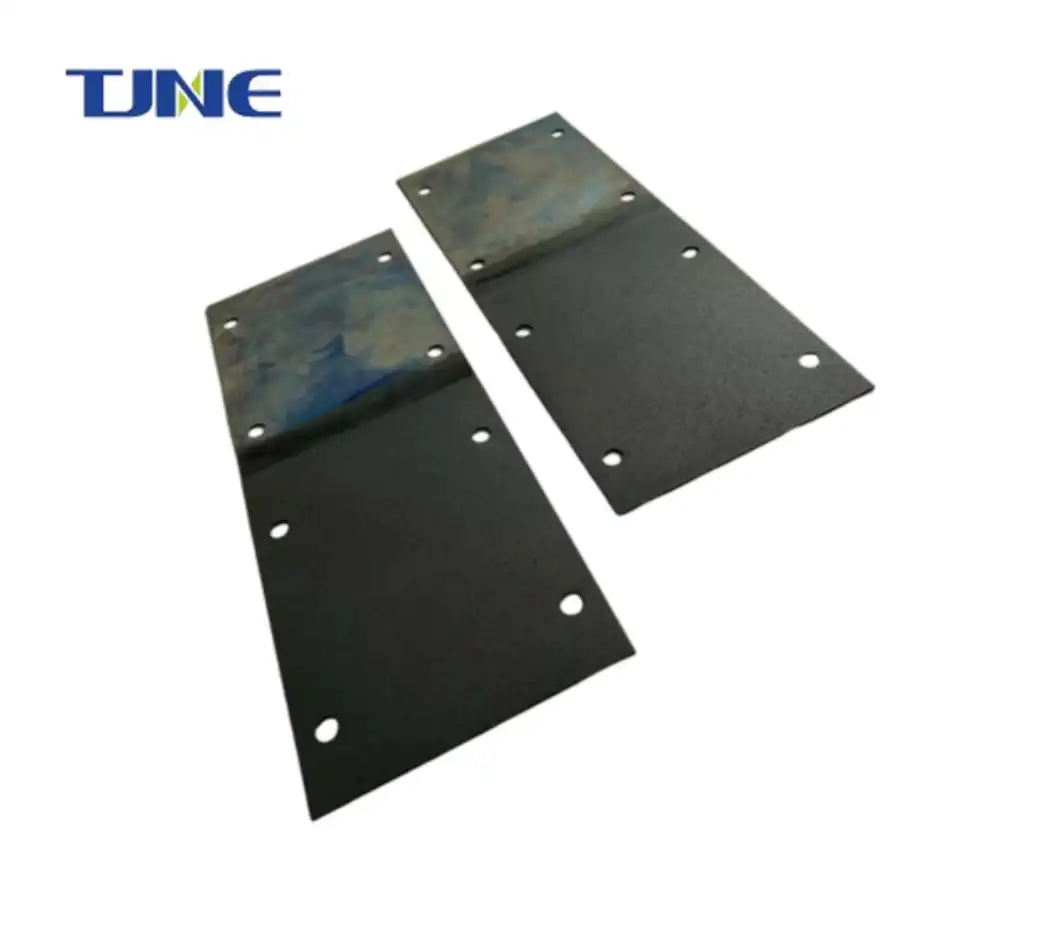

4. Flexibility in installation: MMO Ribbon Anodes are highly flexible and can be easily installed in various configurations. They can be directly buried in soil, embedded in concrete, or submerged in water. This versatility makes them suitable for a wide range of applications and simplifies the installation process.

5. Low maintenance requirements: Due to their stable composition and long lifespan, MMO Ribbon Anodes require minimal maintenance over their operational life. This reduces the need for frequent inspections, replacements, and system downtime, resulting in significant cost savings over time.

These advantages have made MMO Ribbon Anodes the preferred choice in many cathodic protection applications, particularly where long-term reliability, efficiency, and low maintenance are crucial factors. As corrosion prevention becomes increasingly important in maintaining aging infrastructure and ensuring the longevity of new projects, the benefits of MMO Ribbon Anodes are likely to drive their continued adoption and development in the field of cathodic protection.

Where are MMO Ribbon Anodes commonly used in industry applications?

MMO Ribbon Anodes have found widespread use across various industries due to their efficiency, longevity, and versatility in cathodic protection applications. Let's explore some of the most common industry applications where these anodes play a crucial role:

1. Oil and Gas Industry:

- Pipeline Protection: MMO Ribbon Anodes are extensively used to protect both onshore and offshore pipelines from corrosion. Their ability to provide uniform current distribution along long stretches of pipe makes them ideal for this application.

- Offshore Platforms: These anodes protect the submerged portions of offshore oil and gas platforms, including jacket structures, risers, and subsea equipment.

- Storage Tanks: Large storage tanks for oil and gas products benefit from the corrosion protection provided by MMO Ribbon Anodes, both for their base and walls.

2. Marine and Shipping Industry:

- Ship Hulls: MMO Ribbon Anodes are used to protect the hulls of ships and other marine vessels from corrosion caused by seawater.

- Port Structures: Docks, piers, and other port infrastructure exposed to marine environments are protected using these anodes.

- Offshore Wind Farms: The underwater structures of offshore wind turbines are protected from corrosion using MMO Ribbon Anodes.

3. Water Treatment and Distribution:

- Water Storage Tanks: Large water storage tanks, both above ground and underground, use MMO Ribbon Anodes for corrosion protection.

- Water Distribution Networks: These anodes protect underground water pipelines and associated structures from soil-induced corrosion.

- Desalination Plants: The metal components in desalination plants, which are exposed to highly corrosive seawater, are protected using MMO Ribbon Anodes.

4. Construction and Infrastructure:

- Reinforced Concrete Structures: MMO Ribbon Anodes are embedded in concrete to protect reinforcing steel in bridges, parking structures, and other concrete infrastructure.

- Underground Structures: Tunnels, underground storage facilities, and buried metal structures benefit from the protection offered by these anodes.

- Coastal Infrastructure: Sea walls, jetties, and other coastal structures exposed to saltwater use MMO Ribbon Anodes for corrosion protection.

5. Power Generation and Transmission:

- Power Plant Equipment: Cooling water systems, heat exchangers, and other metal components in power plants are protected using these anodes.

- Electrical Grounding Systems: MMO Ribbon Anodes help protect grounding grids and other buried electrical infrastructure from soil corrosion.

- Transmission Towers: The base and underground components of electricity transmission towers are protected using these anodes.

6. Mining Industry:

- Underground Mining Equipment: Metal structures and equipment in underground mines, which are exposed to highly corrosive environments, use MMO Ribbon Anodes for protection.

- Mineral Processing Plants: Various metal components in mineral processing facilities benefit from cathodic protection using these anodes.

7. Chemical and Petrochemical Industry:

- Storage Tanks: Large tanks storing various chemicals and petrochemical products are protected using MMO Ribbon Anodes.

- Process Equipment: Metal components in chemical processing plants, exposed to corrosive substances, use these anodes for protection.

8. Transportation Infrastructure:

- Highway Bridges: Steel reinforcement in concrete bridges, especially those exposed to de-icing salts, are protected using embedded MMO Ribbon Anodes.

- Airport Runways: The steel reinforcement in concrete runways and taxiways at airports use these anodes for corrosion protection.

- Railway Systems: Underground and exposed metal components of railway systems benefit from cathodic protection using MMO Ribbon Anodes.

9. Waste Management:

- Landfill Liners: Metal components in landfill liner systems use these anodes to prevent corrosion from aggressive leachates.

- Wastewater Treatment Plants: Various metal structures and equipment in wastewater treatment facilities are protected using MMO Ribbon Anodes.

10. Renewable Energy:

- Solar Farm Structures: The metal support structures for large-scale solar farms use these anodes for corrosion protection, especially in coastal or high-humidity areas.

- Geothermal Plants: Metal components exposed to corrosive geothermal fluids are protected using MMO Ribbon Anodes.

The widespread use of MMO Ribbon Anodes across these diverse industries underscores their versatility and effectiveness in corrosion protection. As industries continue to focus on extending the lifespan of their assets and reducing maintenance costs, the application of MMO Ribbon Anodes is likely to expand further. Their ability to provide long-lasting, efficient protection in a variety of environments makes them a crucial component in modern corrosion prevention strategies across numerous sectors.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References

1. NACE International. (2021). Cathodic Protection: A Comprehensive Guide.

2. Corrosion Engineering Handbook. (2019). CRC Press.

3. Journal of Corrosion Science and Engineering. (2022). "Advances in MMO Anode Technology for Cathodic Protection."

4. Offshore Technology Conference. (2023). "Application of MMO Ribbon Anodes in Deepwater Structures."

5. American Water Works Association. (2020). "Corrosion Control in Water Distribution Systems."

6. European Federation of Corrosion Publications. (2021). "Marine Corrosion Protection Strategies."

7. Society for Protective Coatings. (2022). "Cathodic Protection of Reinforced Concrete Structures."

8. Oil and Gas Journal. (2023). "Innovations in Pipeline Corrosion Prevention."

9. Materials Performance Magazine. (2021). "Comparing Traditional and MMO Anodes in Industrial Applications."

10. International Journal of Electrochemical Science. (2022). "Long-term Performance of MMO Anodes in Aggressive Environments."