- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electro-Chlorination is a process that produces dilute sodium hypochlorite (bleach) and hydrogen gas by applying an electrical current to saltwater. This process is used for disinfecting water and making it safe for human consumption and other applications. Here are the key points about electrochlorination:

Process

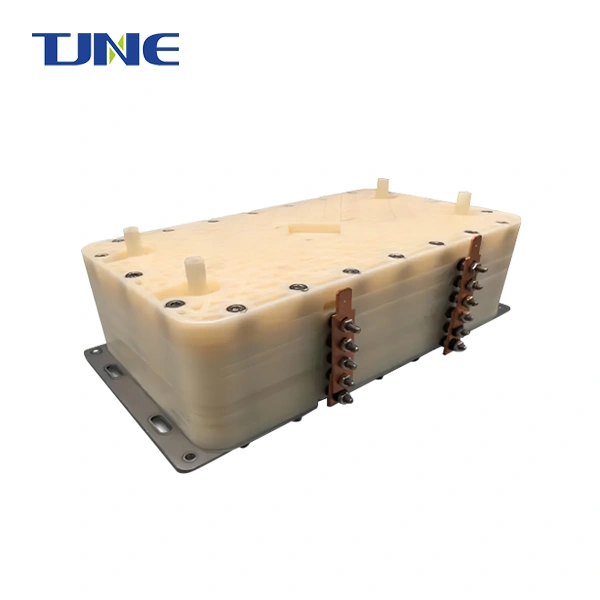

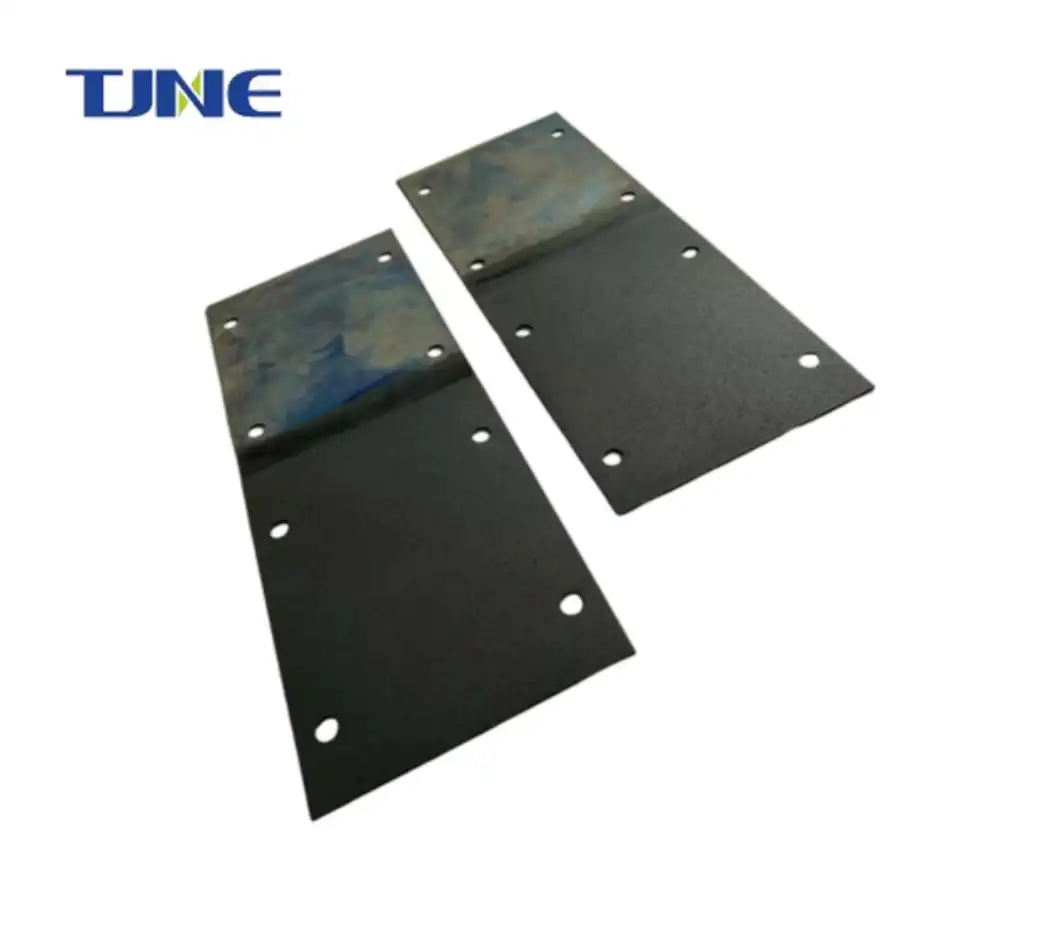

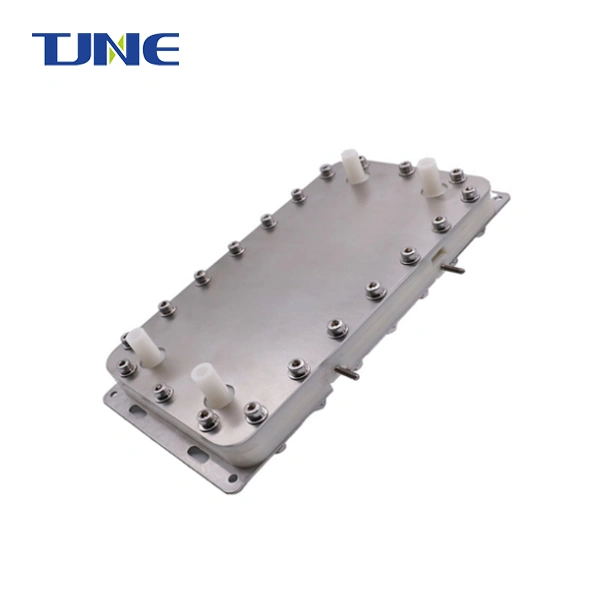

Electrolysis of saltwater: Saltwater is passed through an electrolytic cell with electrodes, where a low voltage DC current is applied.

Chlorine production: At the anode, chloride ions are oxidized to produce chlorine.

Sodium hypochlorite formation: The liberated chlorine reacts with sodium hydroxide to produce sodium hypochlorite.

Hydrogen gas by-product: Hydrogen gas is released at the cathode and separated from the sodium hypochlorite solution due to its low density.

Chemical Reaction

NaCl + H2O + ENERGY → NaOCl + H2

Applications

Drinking water treatment: Electro-Chlorination is used to disinfect drinking water without producing environmental toxins.

Swimming pools: It is used to chlorinate pool water, killing harmful microorganisms and providing a safe environment for swimmers.

Advantages

Non-hazardous and environmentally friendly

No toxic by-products or sludge

No handling of hazardous chemicals like chlorine gas

On-site generation and on-demand production

Economical and efficient

Safety Considerations

Hydrogen gas is highly flammable and explosive, requiring safe management and dispersal.

Risk assessments are necessary for the safe operation of electrochlorination systems.

Electro-Chlorination include: ballast water titanium electrode,chlorine generator electrolyzer,acidic electrolytic water,titanium electrode for swimming pool disinfection,titanium electrode for drinking water disinfection,iridium tantalum coated titanium anode,ruthenium iridium coated titanium anodes,alkaline water electrolyser,titanium electrode for swimming pool disinfection,dsa coating titanium anode.