- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Saltwater Electrolysis

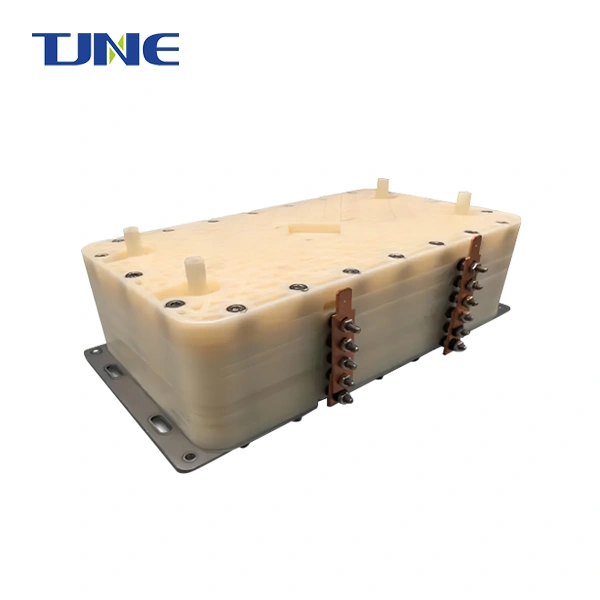

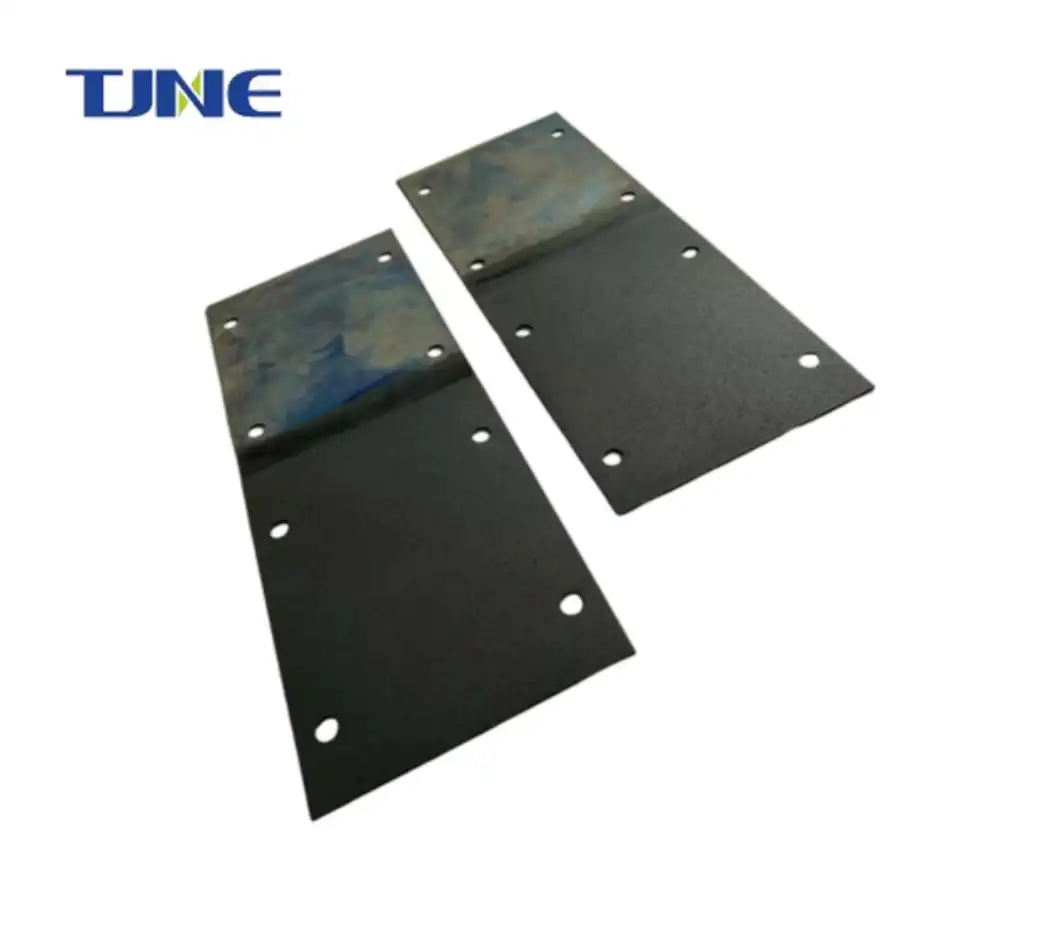

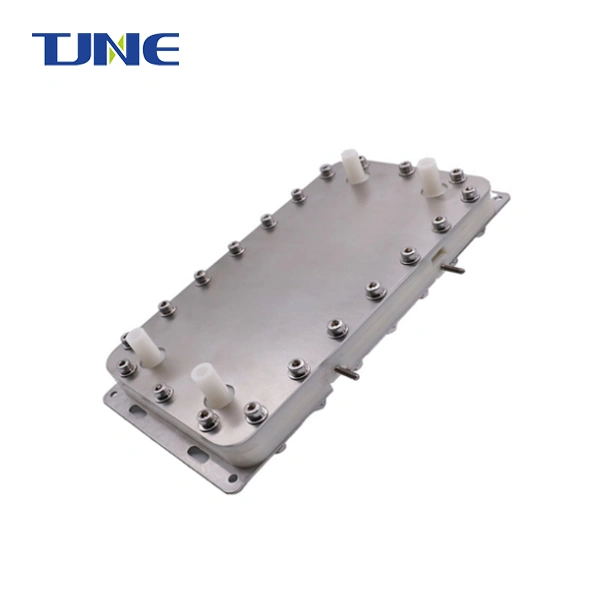

2.Coating: Coated with ruthenium and iridium coatings. Generation of effective chlorine concentration: ≥9000 ppm.

3.Coating thickness: 0.2-20μm, maintaining stable operation in saltwater electrolysis. Chlorine precipitation anode life >5 years, cathode life >20 years.

4.Specification: Available in 50g/h, 100g/h, 200g/h, 300g/h, 1000g/h, 5000g/h and more.

5.Consumption: Salt consumption: ≤2.8 kg/ kg·Cl, DC power consumption: ≤3.5 kwh/kg·Cl.

6.Application: Used for disinfection of hospitals and healthcare facilities, food and beverage industry, water treatment and purification, and swimming pools and spa sanitation.

The titanium electrode for saltwater electrolysis is designed to produce sodium hypochlorite (NaClO) by electrolyzing salt water. The electrode utilizes sodium chloride (NaCl), as the source material to induce a chlorine-grounded detergent, removing dangerous bacteria, contagions, and other microorganisms in water. This method stands out as a modern alternative to traditional chemical disinfection techniques, which often rely on harsh chemicals that can pose risks to both human health and the environment. The use of titanium electrodes enhances the efficiency and effectiveness of the electrolysis process, allowing for the continuous generation of sodium hypochlorite on-site. The titanium electrode for saltwater electrolysis is extensively used in applications for water treatment and sanitation purposes.

The titanium electrode for saltwater electrolysis has become extensively utilized in various applications related to water treatment and sanitation. From swimming pools to municipal water supplies, this technology provides a reliable and safe means of disinfection, ensuring that water remains free from contaminants and safe for public use. Its adoption not only contributes to improved water quality but also aligns with sustainable practices in water management.

Our titanium electrode for saltwater electrolysis utilizes advanced technology to generate powerful oxidants that effectively disinfect water. The electrode is made of high-quality titanium coated with mixed metal oxide (MMO), which is erosion-resistant and ensures long-term continuity. Its key features and advantages are as follows:

Environmentally friendly

Long lifespan and durability

Highly efficient in disinfecting water

Safe and reliable with minimal maintenance requirements

Reduced energy consumption during the disinfection process

Lower operational and maintenance costs compared to traditional disinfection methods

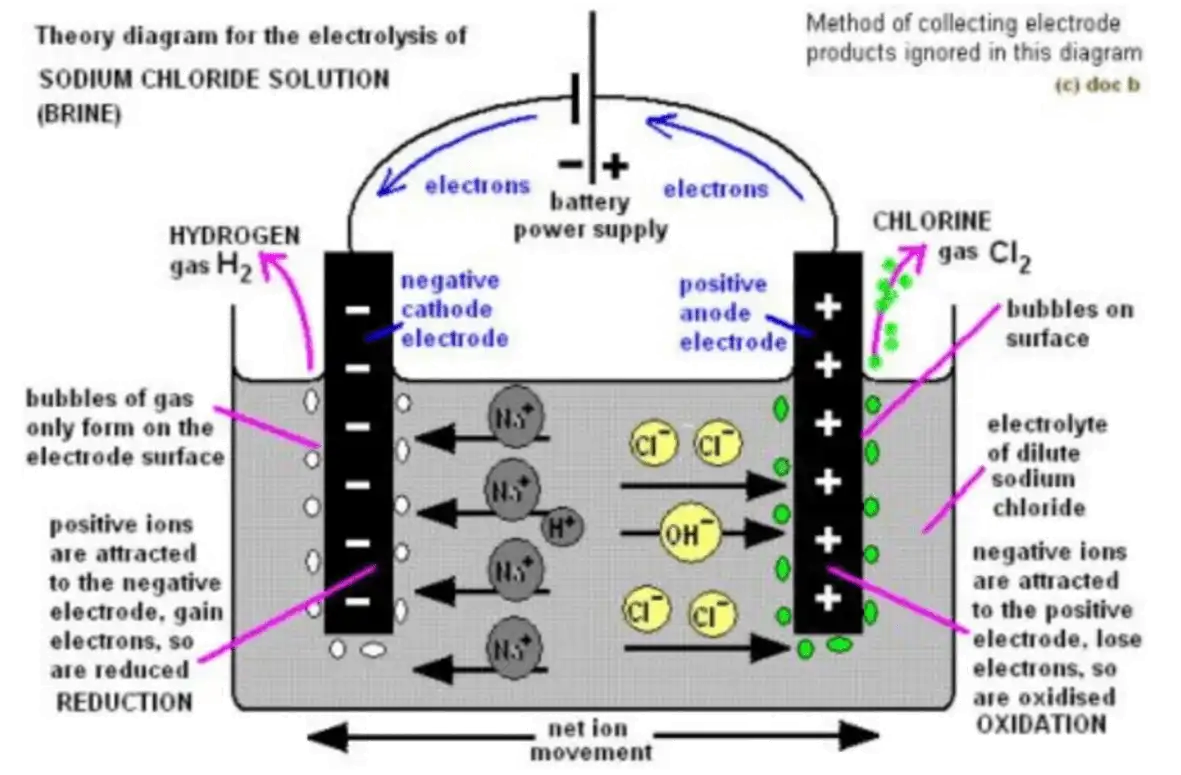

Working Principle

The titanium electrode for saltwater electrolysis works through the process of electrolyzing sodium chloride dissolved in water. The process involves the oxidation of chloride ions (Cl-) at the anode, forming chlorine gas (Cl2), which is also replied with water to produce sodium hypochlorite (NaClO), hypochlorous acid (HOCl) and hypochlorite ions (OCl-). The electrode plates are precisely designed and arranged to ensure maximum face area for electrolysis and enhanced disinfection capabilities. The system is compact, easy to install, and requires minimum conservation.

The total reaction expression is as follows:

NaCl + H2O → NaClO + H2

Application

Hospitals and healthcare facilities

For hospitals and healthcare facilities, the titanium electrode is ideal for robust disinfection of high volumes of water used for medical procedures. By fitting water lines with the electrode, health centers can continuously disinfect their water against bacterial, viral, and fungal contaminants that may threaten patient health and safety. This improves infection control and enables compliance with water regulations.

Food and beverage industry

The food and beverage industry can leverage the titanium electrode to produce clean potable water for use in beverage production, food preparation, cleaning, and other applications where water quality is paramount. Disinfecting process water ensures food safety and adherence to health standards.

Water treatment and purification

At the municipal level, water treatment utilities can utilize the electrode for broad disinfection of public drinking water supplies to protect community health. The sustainable, chemical-free disinfection also supports environmental goals. The technology can disinfect large municipal water volumes cost-effectively.

Swimming pools and spa sanitation

The titanium electrode allows swimming pools, spas, and recreational water facilities to maintain clean, sanitized water for patrons and staff. Automated disinfection replaces manual chlorine dosing while avoiding undesirable chlorine odors and side effects like skin/eye irritation.

Contact Us

If you are considering our titanium electrode for saltwater electrolysis, please feel free to contact us at yangbo@tjanode.com.

We are a professional manufacturer and supplier of titanium electrodes, offering strong technical expertise, comprehensive after-sales service, and reliable certification testing reports. We ensure fast delivery and secure packaging. We also provide support for testing and customization to meet specific requirements.