- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cathodic Protection: MMO belts are widely employed in cathodic protection systems for safeguarding metallic structures and pipelines against corrosion. By serving as impressed current anodes, MMO belts facilitate the sustained flow of protective electrical currents to mitigate the corrosion of buried or submerged metal infrastructure, ensuring long-term structural integrity and safety.

Electrowinning and Electroplating: In metal electrowinning and electroplating processes, MMO belts function as anodes to enable the electrodeposition of metals such as copper, zinc, nickel, and gold. Their high electrocatalytic activity, corrosion resistance, and dimensional stability contribute to efficient metal recovery and high-purity electroplated coatings, enhancing industrial production processes.

Water Treatment and Chlorine Generation: MMO belts play a crucial role in electrochemical water treatment applications, including the generation of chlorine for disinfection purposes. Through electrolysis, these anodes facilitate the production of sodium hypochlorite and other oxidizing agents used in water disinfection, wastewater treatment, and swimming pool sanitation, offering a sustainable alternative to traditional chemical disinfectants.

Electrolytic Production Processes: In various electrolytic processes, such as the production of sodium chlorate, sodium chlorite, perchlorates, and other chemicals, MMO belts contribute to efficient ion exchange, electrochemical reactions, and the generation of valuable chemical compounds. Their robust performance under harsh operating conditions enhances the productivity and cost-effectiveness of industrial electrolysis operations.

Environmental Remediation and Groundwater Treatment: MMO belts are utilized in electrochemical remediation techniques for treating contaminated groundwater and soil. By promoting the degradation of organic pollutants, heavy metals, and chlorinated compounds through electrooxidation and reductive dechlorination, these anodes support sustainable environmental cleanup efforts.

Hydrogen Production and Electrosynthesis: In the field of electrochemical hydrogen generation and electrosynthesis of chemicals, MMO belts serve as effective anodes for electrolysis processes, enabling the sustainable production of hydrogen gas and facilitating diverse electrochemical transformations for the synthesis of value-added chemicals and fuels.

Redox Flow Batteries and Energy Storage: MMO belts are being explored for their potential application in redox flow batteries, a promising energy storage technology. Their chemical stability, high surface area, and electrocatalytic activity make them suitable candidates for enhancing the performance and durability of redox flow battery systems.

In the realm of electrochemistry, the advent of MMO (Mixed Metal Oxide) belts has ushered in a new era of innovation and efficiency. These remarkable devices, with their unique composition and properties, have revolutionized various industries, from wastewater treatment to metal recovery.

The Science Behind MMO Belts

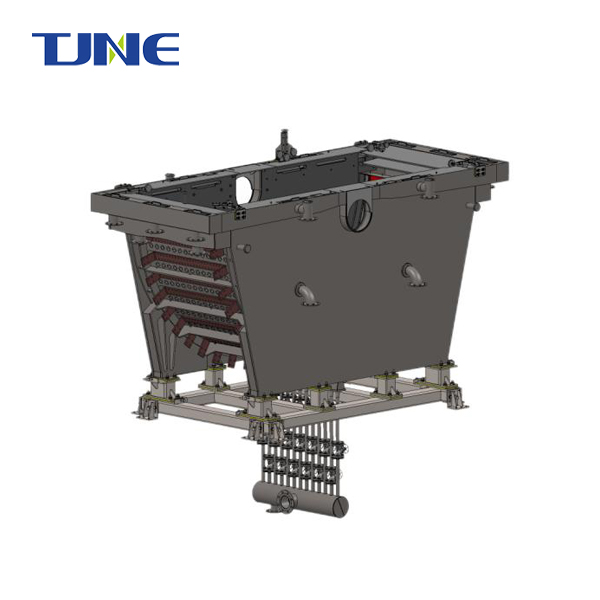

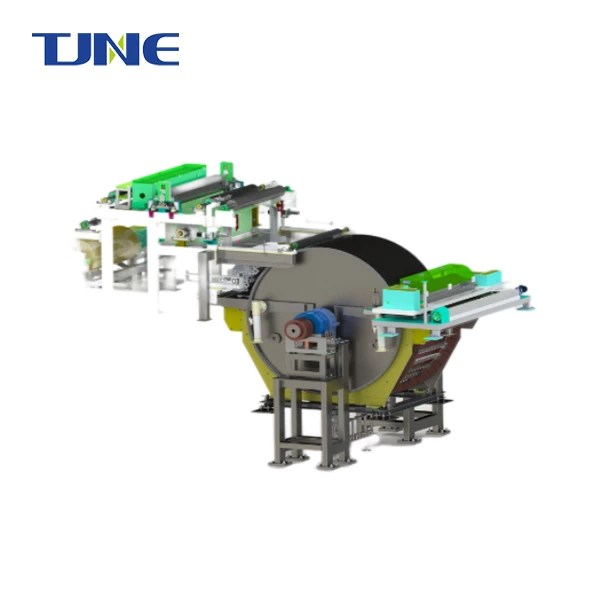

At the heart of MMO belts lies a sophisticated interplay of materials and electrochemical processes. These belts are typically composed of titanium substrates coated with a mixed metal oxide layer. This specialized coating endows the belts with remarkable durability, corrosion resistance, and catalytic activity, making them ideal for electrochemical applications.

The principle behind MMO belts revolves around electrolysis, a process wherein an electric current is passed through a conductive solution, causing chemical reactions to occur at the electrode surfaces. In wastewater treatment, for instance, MMO belts serve as electrodes in electrocoagulation processes, where contaminants are removed through the formation of insoluble precipitates or by electrochemical oxidation.

Breaking New Ground: Innovative Uses of MMO Belts in Industry

The versatility of MMO belts extends far beyond conventional electrochemical processes. In recent years, researchers and engineers have been pushing the boundaries of these devices, exploring novel applications across diverse industries.

One such innovative use is in the realm of metal recovery. By harnessing the selective electrochemical properties of MMO belts, it becomes possible to efficiently extract valuable metals from complex matrices such as electronic waste or industrial effluents. This not only offers a sustainable approach to resource management but also mitigates environmental pollution.

Additionally, MMO belts find application in electrolytic production processes, such as the electrochemical synthesis of specialty chemicals or the deposition of functional coatings on substrates. Their ability to operate under harsh conditions, coupled with their long service life, makes them indispensable in various manufacturing operations.

Comparative Advantages: Why MMO Belts Outperform Traditional Solutions

When compared to conventional electrodes and treatment methods, MMO belts offer a myriad of advantages that set them apart. Firstly, their robust construction and corrosion resistance ensure prolonged service life, reducing maintenance costs and downtime. Moreover, the catalytic activity of the mixed metal oxide coating enhances process efficiency, enabling faster reaction kinetics and higher yields.

Furthermore, MMO belts exhibit superior performance in terms of energy efficiency and selectivity. By precisely controlling the electrode potential and surface properties, it becomes possible to achieve targeted electrochemical transformations with minimal energy consumption. This not only translates to cost savings but also reduces the carbon footprint of industrial processes.

Looking to the Future: Emerging Trends in MMO Belt Technology

As technology continues to advance, so too do the capabilities of MMO belts. One notable trend is the integration of smart sensors and monitoring systems, allowing for real-time feedback and control of electrochemical processes. This enables optimization of operating parameters, predictive maintenance, and enhanced process automation.

Additionally, ongoing research efforts are focused on further enhancing the catalytic performance and stability of MMO coatings, thereby expanding their applicability to new domains such as renewable energy storage and conversion. By harnessing the synergies between materials science, electrochemistry, and digital technologies, the future holds immense promise for the continued evolution of MMO belt technology.

Conclusion

In conclusion, MMO belts represent a paradigm shift in electrochemical engineering, offering unparalleled performance, durability, and versatility across a wide range of applications. Their transformative impact on industries such as cathodic protection, wastewater treatment, metal recovery, and manufacturing underscores their importance in the pursuit of sustainable development and technological innovation.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of MMO Belt, welcome to contact us: yangbo@tjanode.com

References

1. Li, X., Huang, X., & Li, C. (2019). Mixed metal oxide electrode materials for electrochemical capacitors. Frontiers in Chemistry, 7, 63.

2. Chen, Z., & Fan, G. (2020). Electrochemical treatment of wastewater using MMO-coated titanium electrodes. Chemical Engineering Journal, 398, 125683.

3. Wang, Y., Li, J., & Wang, C. (2021). Recent advances in the application of MMO coatings in electrochemical processes. Electrochimica Acta, 381, 138274.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes

- The Power of Splitting Water: An In-Depth Look at Alkaline Water Electrolyzers

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What Factors Should Be Considered When Selecting a DSA Anode?

- Which electrolyzer is best for hydrogen production?