English

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

SEARCH

.webp)

.webp)

.webp)

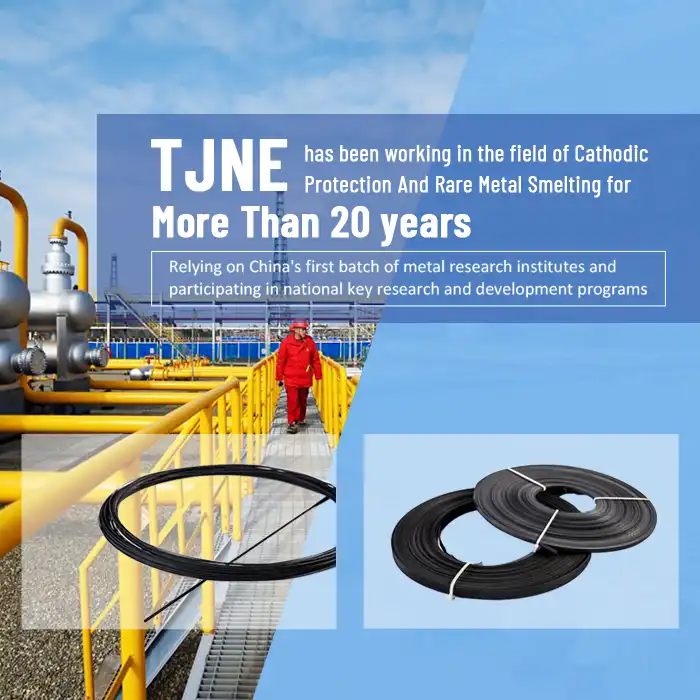

About TJNE

The holding subsidiary of Northwest Insititute for Non-ferrous Metal Research, adhering to the purpose of replacing imports, filling gaps and solving urgent needs, serves the field of new materials and new energy.

The most advanced laboratory in the field of titanium electrode research and development in China has been built.

TJNE is the earliest and only company in China that has developed mature and stable titanium-based lead dioxide anodes for mass production and application.

We have also taken the initiative to undertake a number of national research projects.

View MoreThe most advanced laboratory in the field of titanium electrode research and development in China has been built.

TJNE is the earliest and only company in China that has developed mature and stable titanium-based lead dioxide anodes for mass production and application.

We have also taken the initiative to undertake a number of national research projects.

Production Introduction

Xi'an Taijin New Energy

Technology Co., Ltd., a

leading enterprise in new

energy technology, operates

three distinct factory areas

in Xi'an.

Mission&Vision

Provide green technologies

with electrode material

innovation and high-end

intelligent equipment

structure innovation as the

core.

Core Team

Established research

cooperation relationships

with various universities

and research institutes,

forming an innovative tech

team.

Our Products

VIEW OUR WIDE RANGE OF QUALITY PRODUCTS

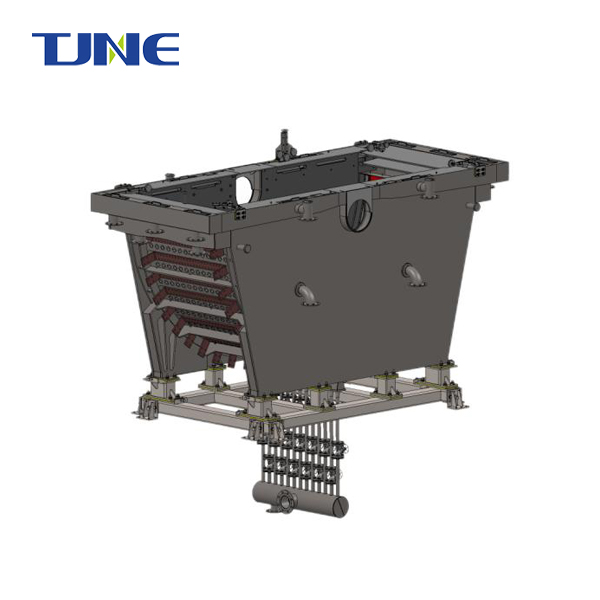

High Efficiency Copper Dissolution Tank

Product name: High efficiency Copper Dissolution Tank

Product Overview: It is a device used to dissolve copper in the copper foil production process. Its main function is to dissolve copper ions in water to form an electrolyte.

Product advantages: efficient dissolution, stable operation, environmental protection and energy saving, easy maintenance, and high safety.

Technical advantages:

1. Maximize the copper-melting reaction speed and heat release without steam heating.

The negative pressure air formed in the tank is self-primed to reduce energy consumption.

2. The self-developed system improves the copper dissolving efficiency, and the copper dissolving efficiency can reach 260kg/h.

3. The guaranteed copper amount is ≤35 tons (the industry average is 80~90 tons), reducing system costs.

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

View MoreProduct Overview: It is a device used to dissolve copper in the copper foil production process. Its main function is to dissolve copper ions in water to form an electrolyte.

Product advantages: efficient dissolution, stable operation, environmental protection and energy saving, easy maintenance, and high safety.

Technical advantages:

1. Maximize the copper-melting reaction speed and heat release without steam heating.

The negative pressure air formed in the tank is self-primed to reduce energy consumption.

2. The self-developed system improves the copper dissolving efficiency, and the copper dissolving efficiency can reach 260kg/h.

3. The guaranteed copper amount is ≤35 tons (the industry average is 80~90 tons), reducing system costs.

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

Copper Foil Anode

Product name: Copper Foil Anode

Product Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.

Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.

Technical advantages:

Long life: ≥40000kAh m-2 (or 8 months)

High uniformity: coating thickness deviation ±0.25μm

High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V

Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

View MoreProduct Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.

Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.

Technical advantages:

Long life: ≥40000kAh m-2 (or 8 months)

High uniformity: coating thickness deviation ±0.25μm

High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V

Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

Titanium Anode Tank

Product name: Titanium Anode Tank

Product overview: It plays an important role in the production process of electrolytic copper foil. Its performance and quality directly affect the quality and output of copper foil.

Product advantages: good electrochemical performance, corrosion resistance, high-precision processing, reasonable and safe structure, etc.

Technical advantages:

a. Independently developed all-titanium welding technology

b. High precision: inner arc surface roughness ≤ Ra1.6

c. High rigidity: coaxially ≤±0.15mm; diagonal ≤±0.5mm, width ≤±0.1mm

d. High strength: no leakage within 5 years

e. Full specifications: Possessing the design and manufacturing capabilities for anode slots with a diameter of 500~3600mm

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

View MoreProduct overview: It plays an important role in the production process of electrolytic copper foil. Its performance and quality directly affect the quality and output of copper foil.

Product advantages: good electrochemical performance, corrosion resistance, high-precision processing, reasonable and safe structure, etc.

Technical advantages:

a. Independently developed all-titanium welding technology

b. High precision: inner arc surface roughness ≤ Ra1.6

c. High rigidity: coaxially ≤±0.15mm; diagonal ≤±0.5mm, width ≤±0.1mm

d. High strength: no leakage within 5 years

e. Full specifications: Possessing the design and manufacturing capabilities for anode slots with a diameter of 500~3600mm

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

Copper Foil Surface Treatment Machine

Product name: Copper foil surface treatment machine

Product Overview: A device specially used for surface treatment of electrolytic copper foil, aiming to improve the performance of copper foil.

Equipment composition: rewinding and unwinding device, detection system, power system, conductive system,

Spray washing and drying device, spray device, liquid roller transmission sealing device,

Safety/protection devices, electrical equipment, and control systems, electrolytic water washing tanks, etc.

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

View MoreProduct Overview: A device specially used for surface treatment of electrolytic copper foil, aiming to improve the performance of copper foil.

Equipment composition: rewinding and unwinding device, detection system, power system, conductive system,

Spray washing and drying device, spray device, liquid roller transmission sealing device,

Safety/protection devices, electrical equipment, and control systems, electrolytic water washing tanks, etc.

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

MMO Anode Plate

1.Substrate material: ASTM B 265GR1

2.Specifications: Available in various width, thickness to fit different industrial requirements

3.Coating: Coated with ruthenium and iridium, with a service life more than 20 years

4.Coating thickness: 8-15μm, perfecting the overall effectiveness of the anode

5.Operating temperature: 10°C to 60°C

6.Advantage highlights: long life, low energy consumption, low comprehensive use cost, high cost performance

7.Application: Used for cathodic protection for corrosion prevention in seawater environment

View More2.Specifications: Available in various width, thickness to fit different industrial requirements

3.Coating: Coated with ruthenium and iridium, with a service life more than 20 years

4.Coating thickness: 8-15μm, perfecting the overall effectiveness of the anode

5.Operating temperature: 10°C to 60°C

6.Advantage highlights: long life, low energy consumption, low comprehensive use cost, high cost performance

7.Application: Used for cathodic protection for corrosion prevention in seawater environment

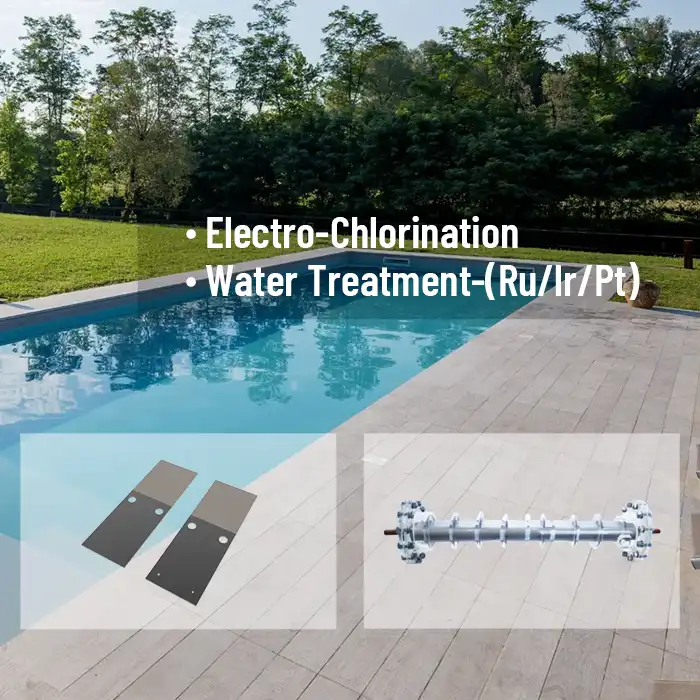

Seawater Electrolysis

1.Material: Made of GR1, GR2 titanium material. Available in plate, mesh shapes with thickness of 1mm, 1.5mm, 2mm, 2.5mm and more.

2.Coating: Coated with ruthenium and iridium, ruthenium- iridium- platinum coatings. The chlorination potential is less than and equal to 1.1V.

3.Coating thickness: 0.2-20μm, maintaining stable operation in seawater electrolysis. Chlorine precipitation anode life >5 years, cathode life >20 years.

4.Working temperature: 5-40°C

View More2.Coating: Coated with ruthenium and iridium, ruthenium- iridium- platinum coatings. The chlorination potential is less than and equal to 1.1V.

3.Coating thickness: 0.2-20μm, maintaining stable operation in seawater electrolysis. Chlorine precipitation anode life >5 years, cathode life >20 years.

4.Working temperature: 5-40°C

Chlorine Electrolysis Cell

1.Material: Made of GR1, GR2 titanium material.

2.Coating: Coated with ruthenium and iridium coatings, with a service life more than 5 years.

3.Generation of effective chlorine concentration: ≥9000 ppm.

4.Coating thickness: 0.2-20μm, maintaining stable operation in seawater electrolysis. 5.Specification: Available in 50g/h, 100g/h, 200g/h, 300g/h, 1000g/h, 5000g/h and more.

6.Consumption: Salt consumption: ≤2.8 kg/ kg·Cl, DC power consumption: ≤3.5 kwh/kg·Cl.

7.Application: Animal husbandry disinfection, circulating water descaling, disinfection of drinking water, ship ballast water treatment, chemical manufacturing, and swimming pool disinfection.

View More2.Coating: Coated with ruthenium and iridium coatings, with a service life more than 5 years.

3.Generation of effective chlorine concentration: ≥9000 ppm.

4.Coating thickness: 0.2-20μm, maintaining stable operation in seawater electrolysis. 5.Specification: Available in 50g/h, 100g/h, 200g/h, 300g/h, 1000g/h, 5000g/h and more.

6.Consumption: Salt consumption: ≤2.8 kg/ kg·Cl, DC power consumption: ≤3.5 kwh/kg·Cl.

7.Application: Animal husbandry disinfection, circulating water descaling, disinfection of drinking water, ship ballast water treatment, chemical manufacturing, and swimming pool disinfection.

DSA Anode

Substrate: TA1, TA2 titanium material.

Coating: Mixed metal oxide including ruthenium, iridium, tantalum, platinum, etc.

Product advantages: Excellent corrosion resistance, low oxygen evolution overvoltage, environmentally friendly and energy saving.

Application areas: metal electrowinning, electroplating industry, water treatment, cathodic protection, etc.

Service: We provide timely and high-quality new anode manufacturing and delivery globally.

View MoreCoating: Mixed metal oxide including ruthenium, iridium, tantalum, platinum, etc.

Product advantages: Excellent corrosion resistance, low oxygen evolution overvoltage, environmentally friendly and energy saving.

Application areas: metal electrowinning, electroplating industry, water treatment, cathodic protection, etc.

Service: We provide timely and high-quality new anode manufacturing and delivery globally.

Quality Assurance

TJNE founded in 2000, is a high-tech industrial

company mainly engaged in the research and

development, manufacturing, testing, inspection, and

technical service of electrode materials and high-end

electrolytic equipment.

We have established research cooperation relationships

with various universities and research institutes,

forming an innovative tech team.

News

- The First Forum on Titanium Industry Development Between China and the CIS was held in Xi’an On October 16, 2024, under the guidance of the Titanium Zirconium Hafnium Branch of China Nonferrous Metals Industry Association and the International Titanium Association of the CIS (Commonwealth of Independent States), the Forum on Titanium Industry Development Between China and CIS hosted by the Northwest Institute for Non-ferrous Metals Research and Baoji Titanium Industry Co., Ltd. was held in Xi’an, Shaanxi Province.

- TJNE participated in the Shenzhen HKPCA Show TJNE brought a variety of insoluble titanium anode products with excellent performance in printed circuit board (PCB) electroplating technology and application fields to the exhibition, attracting the attention of many visitors with high-quality products and technical strength. These titanium anode products not only have excellent performance advantages, but also demonstrate TJNE's deep R&D accumulation and technological innovation capabilities in the field of electroplating.

- TJNE’S Invitation to Watertech China 2025 TJNE focuses on the research and development, design, production, and sales of special titanium electrode materials, which are applied in fields such as electrolytic chlorine production, electrolytic ozone production, electrolytic hydrogen production, advanced catalytic oxidation, and scale removal and sterilization, providing customers with solutions and core materials for green electrolysis technology in water treatment.

Clients

icms_en_6090db10722011ee8c8c3f99e7f16f08