- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

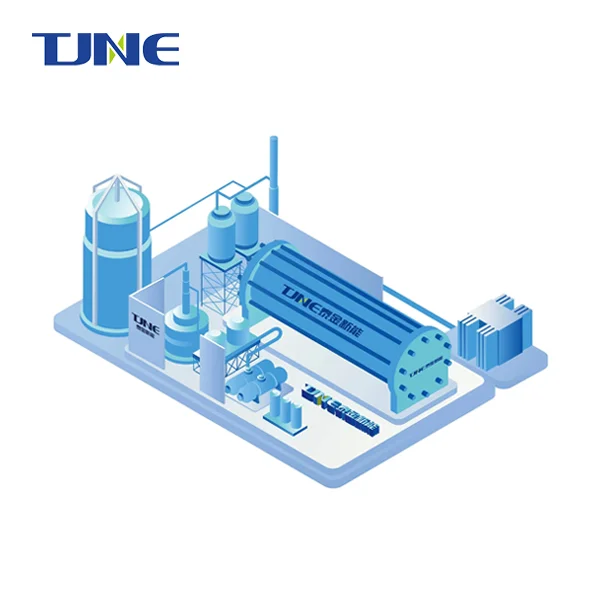

In chemical engineering specializing in electrolysis processes, we find the intricacies of chlorine generator electrolyzers both fascinating and essential to modern industrial applications. In this article, we will delve into the workings of these electrolyzers, exploring their electrochemical reactions, the pivotal role of electrodes, and the diverse configurations employed in chlorine generation.

Electrolysis Process

The operation of a chlorine generator electrolyzer relies on electrolysis, a fundamental process where an electric current induces chemical reactions at the electrodes submerged in an electrolyte solution. In the case of chlorine generation, the electrolyte typically consists of brine (sodium chloride solution).

During electrolysis, two primary electrochemical reactions occur:

Chlorine Production at Anode:

At the anode (positive electrode), chloride ions (Cl-) from the brine solution undergo oxidation. This results in the release of chlorine gas (Cl2) according to the following reaction:2Cl⁻(aq) → Cl2(g) + 2e⁻

Hydrogen Production at Cathode:

Simultaneously, at the cathode (negative electrode), water molecules (H2O) are reduced to produce hydrogen gas (H2) and hydroxide ions (OH-) through the reaction:2H2O(l) + 2e⁻ → H2(g) + 2OH⁻(aq)

These reactions are essential for the continuous generation of chlorine gas in a chlorine generator electrolyzer.

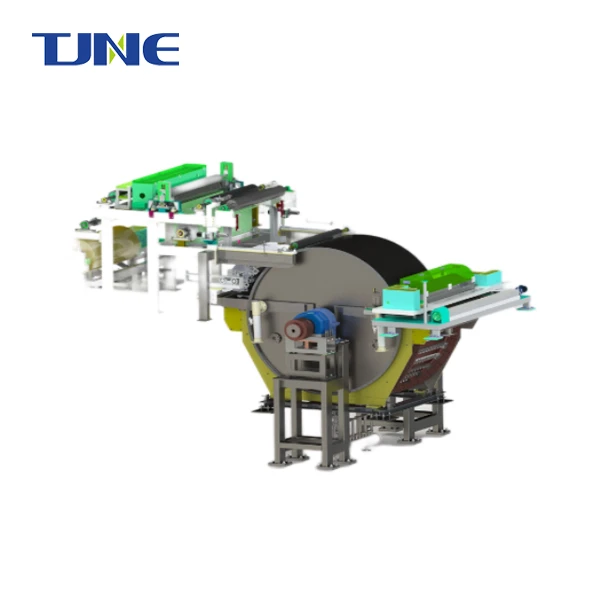

Role of Electrodes

Electrodes play a crucial role in facilitating the conversion of brine into chlorine gas. Typically made of materials resistant to corrosion and capable of conducting electricity, such as titanium coated with noble metals like ruthenium or iridium, the electrodes serve specific functions:

Anode:

The anode initiates the oxidation reaction of chloride ions, liberating chlorine gas. It must withstand the corrosive environment and efficiently promote the desired electrochemical reaction without undergoing degradation.

Cathode:

Conversely, the cathode facilitates the reduction of water molecules, generating hydrogen gas. Like the anode, the cathode material must exhibit durability and high catalytic activity to ensure efficient electrolysis.

The proper design and materials selection for electrodes are critical to the performance and longevity of chlorine generator electrolyzers.

Furthermore, electrodes contribute to the optimization of energy usage in electrochemical processes. By giving a pathway to electron move, cathodes empower the transformation of electrical energy into substance energy as well as the other way around, making them fundamental parts of energy capacity and changing gadgets like batteries and power modules.

In summary, electrodes are indispensable in the realm of electrochemistry, serving as the sites for electron transfer and redox reactions. Their diverse roles encompass facilitating efficient electron transfer, influencing reaction selectivity, and enabling the development of advanced technologies for energy storage and chemical synthesis. As innovative work in electrochemistry keeps on propelling, anodes will stay at the front of development, driving advancement in different fields including reasonable energy, materials science, and compound assembling.

Electrolyzer Configurations

Various electrolyzer configurations are employed in chlorine generation, each offering distinct advantages depending on specific application requirements. Some common designs include:

Membrane Electrolyzers:

These electrolyzers incorporate ion-exchange membranes to separate the anode and cathode compartments, preventing the mixing of chlorine and hydrogen gases. Membrane electrolyzers are known for their high purity chlorine production and operational flexibility.

Diaphragm Electrolyzers:

Diaphragm electrolyzers utilize porous diaphragms to physically separate the anode and cathode chambers, allowing ion transport while impeding gas crossover. Although less efficient than membrane systems, diaphragm electrolyzers are renowned for their robustness and suitability for harsh operating conditions.

Mercury Cell Electrolyzers (historical):

In the past, mercury cell electrolyzers were prevalent in chlorine production. However, due to environmental concerns associated with mercury usage, they have largely been phased out in favor of more environmentally friendly alternatives.

The choice of electrolyzer configuration depends on several factors, including the scale of operation, required purity of products, energy input, and specific application requirements. For instance, antacid electrolyzers are appropriate for enormous-scope hydrogen creation because of their heartiness and long-haul dependability, while PEM electrolyzers are liked for more limited-size applications where fast reaction times and high-immaculateness hydrogen are fundamental.

Lately, progressions in electrolyzer innovation have zeroed in on further developing effectiveness, decreasing expenses, and improving the coordination of environmentally friendly power sources. Electrolyzers are progressively being incorporated with inexhaustible power sources, for example, sun-oriented and wind to deliver green hydrogen, adding to the decarbonization of different modern areas.

By and large, electrolyzer arrangements keep on advancing, driven by the developing interest for economical and effective hydrogen creation, as well as the growing utilization of electrolysis in energy capacity, synthetic blend, and ecological remediation. Electrolyzers are anticipated to become increasingly important in the shift toward a low-carbon and more sustainable economy as research and development progress.

Contact Us

In conclusion, chlorine generator electrolyzers play a pivotal role in industrial processes requiring reliable and efficient chlorine production. By understanding the electrochemical reactions, the significance of electrodes, and the diverse electrolyzer configurations available, engineers and operators can optimize chlorine generation for various applications while adhering to stringent safety and environmental standards.

If you want to learn more about these electrolyzers, feel free to contact us at yangbo@tjanode.com.

References

1.G. K. Srinivasan, "Electrochemistry of hydrogen evolution and chlorine evolution", Springer Science & Business Media, 2012.

2.H. A. Laitinen, "Chlorine production and the electrolysis process", John Wiley & Sons, 2019.

3.R. W. Stark, "Electrochemical Chlorine Technology", CRC Press, 2016.

Related Industry Knowledge

- How Do Anodes Facilitate the Removal of Ammonia Nitrogen from Water?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- What Makes PCB RPP Copper Plating Essential for Durable Surface Area Enhancement?

- How Does PCB VCP DC Copper Plating Work in Direct Current Systems?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What Industries Rely on DSA Anodes for Electrochemical Processes?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?