- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

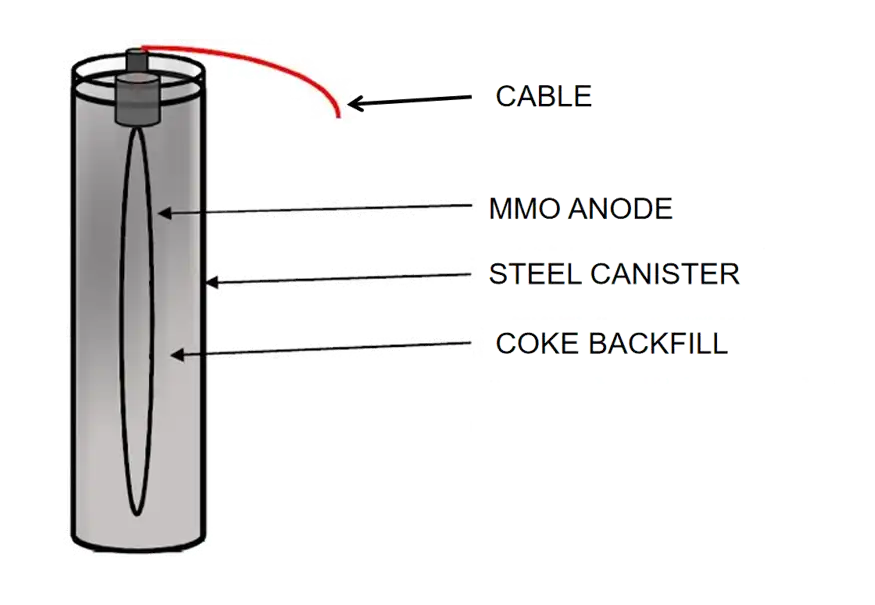

MMO Canister Anode

2.Coating: Iridium-tantalum coating, in line with NACE Standard TM0108-2008

3.Specification: Customized according to customer requirements, the type of actual anode inside the canister includes tubular, , wire, rod, ribbon and others

4.Cable type and size: XLPE/PVC、PVC/PVC, HMWPE、KYNAR/HMWPE, PVDF/HMWPE, etc.

5.Application: Suitable for cathodic protection projects, and can also be connected in chains

6.Product after-sales service: We provide timely and high-quality services worldwide

The MMO Canister Anode manufactured by TJNE is a high-performance anode solution designed for various corrosion protection applications. With strong technical expertise, comprehensive after-sales service, complete certification and testing reports, fast delivery, and secure packaging, TJNE is your reliable partner. The mixed metal oxide (MMO) Canister Anode consists of an MMO anode made from a titanium substrate coated with a mixed metal oxide of iridium and tantalum and a galvanized steel canister. It is specifically designed to provide efficient and long-term corrosion protection, such as cathodic protection for metallic pipelines and storage tanks. The mixed metal oxide catalyst on the mixed metal oxide (MMO) Canister Anode provides excellent chemical stability and catalytic activity, ensuring a long lifespan and high corrosion protection efficiency. It has superior resistance to chlorine and other aggressive substances commonly found in corrosive environments. It has the following features:

Cylindrical shape for efficient current distribution, and multiple shapes of actual anode, including tubular, wire, mesh, etc.

Optimized catalyst thickness ranging from 8 to 15 μm with excellent chemical stability and catalytic activity for optimal performance

Durable and robust construction for long-term use for more than 20 years

Wide range of operating temperatures from 10 to 60℃ to suit different applications

Working principle and structure

The MMO Canister Anode operates based on the principle of impressed current cathodic protection (ICCP). It utilizes the electrochemical reactions between the MMO catalyst and the surrounding electrolyte to generate a protective current that counteracts corrosion on metallic structures. It mainly consists of following components:

1. MMO anode: Consists of titanium substrate which provides a solid and durable base for the anode and MMO catalyst applied to the titanium substrate which enables efficient electron transfer and corrosion protection.

2. Steel canister: Encases the anode components, providing mechanical protection and facilitating installation.

3. Coke Backfill: Enhances the electrical conductivity, and has favorable thermal properties that help manage temperature variations.

4. Cable: Allows for easy connection to the power supply for the impressed current cathodic protection system.

Applications

Mixed metal oxide (MMO) canister anodes have become an important cathodic protection technology to mitigate corrosion across industrial infrastructure sectors like metallic pipelines, and above-ground storage tanks.

Metallic pipelines

A major application is safeguarding buried metallic pipelines. It is buried adjacent to underground pipelines and provides protective current flows that counter pipeline corrosion from soil elements. This sustains pipeline integrity and prevents leaks or failures.

Above-ground storage tanks

For above-ground storage tanks containing corrosive substances like brine or acids, MMO canister anodes attached to tank surfaces neutralize external corrosion by supplying protective current to shielded areas. This maintains tank integrity and prevents environmental contamination.

With its robust design and mounting versatility, it offers flexible integration for corrosion protection across key infrastructure. As assets age worldwide, MMO canister anodes will see expanded usage to combat corrosion threats in critical marine and onshore applications.

FAQ

1. What is the lifespan?

It has a design life of up to 20 years, depending on the environmental conditions and operating parameters.

2. Can it be customized for specific applications?

Yes, TJNE offers a range of sizes and configurations to cater to different project requirements.

3. Is it compatible with various electrolytes?

Yes, it has excellent chemical stability and can be used in various electrolyte environments.

We are a leading provider of MMO anode products. For more information about our MMO Canister Anode products, please contact us at yangbo@tjanode.com.