- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

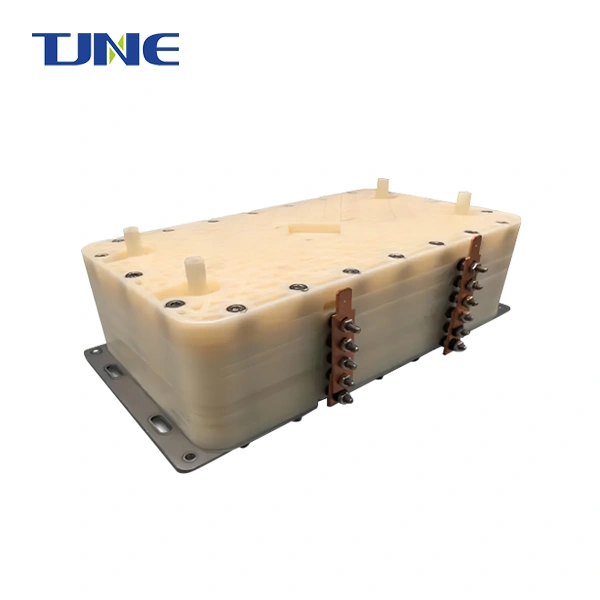

In today's industrial landscape, the role of DSA Anodes in various electrochemical processes is paramount. DSA Anodes are known for their solidness, security, and protection from consumption, making them ideal for delayed use in unforgiving conditions. Most of the time, they are made of a mixture of precious metals like titanium, tantalum, or niobium that are coated with a thin layer of mixed metal oxides. From the production of chlorine and caustic soda in the Chlor-Alkali industry to water treatment applications and electroplating processes, they play a crucial role. Let's delve into each of these industries to understand the significance of the anodes in their operations.

Chlor-Alkali Industry

The chlor-alkali industry plays a vital role in supplying essential chemicals for various sectors while adapting to evolving market dynamics and sustainability challenges. This industry stands as one of the foremost sectors relying on DSA Anodes for its electrochemical processes. In this industry, they are dominatingly used in the electrolysis of salt water (sodium chloride answer for) produce chlorine gas, harsh pop (sodium hydroxide), and hydrogen gas.

During the electrolysis process, the anodes offer several advantages over traditional graphite or metal anodes. Their superior durability and resistance to deterioration are their most significant advantages, particularly in environments with high corrosiveness. This durability ensures prolonged operational efficiency and reduces downtime for maintenance, thereby enhancing overall productivity.0090

Moreover, they exhibit excellent electrocatalytic properties, facilitating the efficient conversion of chloride ions into chlorine gas at the anode. This results in improved process efficiency and higher purity of the chlorine produced. Additionally, the use of the anodes contributes to reduced energy consumption and lower operating costs due to their enhanced catalytic activity and stability. Through improving resource efficiency, reducing greenhouse gas emissions, minimizing emissions, promoting circular economy practices, and mitigating environmental concerns, investments in cleaner technologies and renewable energy sources are driving the industry towards a more sustainable future.

Water Treatment Applications

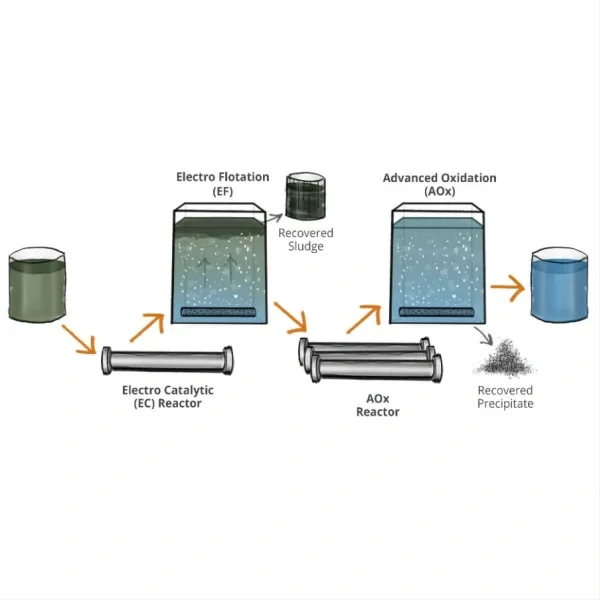

In the realm of water treatment, DSA Anodes play a vital role in various processes aimed at disinfection and wastewater treatment. Electrochemical disinfection is one of the primary uses for the anodes in water treatment. In electrolytic systems, they are used to produce oxidizing agents like chlorine or ozone for disinfection.The use of them in electrochemical disinfection offers numerous benefits. Their high efficiency in generating oxidants ensures effective microbial inactivation, making them an environmentally friendly alternative to traditional chemical disinfection methods. Furthermore, the anodes contribute to the removal of organic pollutants and pathogens from wastewater through electrooxidation processes, thereby aiding in water purification efforts.

Another crucial application of them in water treatment is electrocoagulation, where they assist in the removal of suspended solids, heavy metals, and other contaminants from wastewater. By generating coagulant species such as iron or aluminum ions at the anode surface, they facilitate the destabilization and subsequent removal of impurities through precipitation or flotation mechanisms.

Electroplating and Surface Finishing

In the realm of electroplating and surface finishing, DSA Anodes are indispensable for achieving high-quality plating results and enhancing the durability and aesthetic appeal of metal coatings. They are commonly used in various electroplating processes, including nickel plating, chromium plating, and copper plating, among others.

The utilization of the anodes in electroplating offers several advantages. Their superior corrosion resistance and catalytic activity ensure uniform deposition of metal ions onto the substrate surface, resulting in smooth and adherent coatings with enhanced corrosion resistance. Additionally, the anodes enable precise control over plating parameters such as current density and deposition rate, leading to improved process efficiency and product quality.

Furthermore, they find applications in surface finishing techniques such as anodizing, where they facilitate the formation of durable and decorative oxide layers on metal surfaces. By providing a stable and uniform current distribution during the anodizing process, they ensure consistent oxide layer thickness and surface appearance, thereby enhancing the aesthetic and functional properties of the finished product.

Contact Us

In conclusion, the widespread adoption of DSA Anodes across various industries underscores their importance in modern electrochemical processes. From the Chlor-Alkali industry to water treatment applications and electroplating processes, the anodes continue to drive innovation and efficiency, offering sustainable solutions for diverse industrial challenges.The advantages of DSA Anodes encompass longevity, reliability, efficiency, and environmental sustainability, positioning them as essential components in modern industrial processes. Their continued development and application are expected to further enhance the efficacy and sustainability of electrochemical operations across industries.

If you want to learn more about this kind of it, welcome to contact us at yangbo@tjanode.com.

References

1.Wang, Z., & Xu, L. (2019). Application of Dimensionally Stable Anodes (DSAs) in Electrochemical Water Treatment: A Review. Journal of Electroanalytical Chemistry, 851, 113440.

2.Comninellis, C. (2016). Electrocatalysis in the Electrochemistry of Water Treatment. Electrochimica Acta, 209, 737-746.

3.Teng, Y., & Jiao, K. (2020). Recent Advances in Dimensionally Stable Anodes for Metal Electrowinning and Electroplating. Electrochimica Acta, 331, 135424.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?