- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes

Ruthenium-iridium coated titanium anodes have indeed played a transformative role in various industries, particularly in electrochemical applications. These specialized anodes offer exceptional performance and durability, making them valuable assets in processes such as metal electrowinning, water treatment, and the production of chemicals through electrolysis. Here are some key points highlighting the power of ruthenium iridium coated titanium anodes in revolutionizing industries:

Erosion Resistance: The titanium substrate gives great erosion resistance, whereas the ruthenium-iridium coating assist improves this property, empowering the anodes to withstand cruel chemical situations and delayed utilize in mechanical settings.

Electrochemical Steadiness: The combination of titanium with ruthenium and iridium coatings comes about in tall electrochemical steadiness, guaranteeing that the anodes keep up their execution over amplified periods of operation, indeed beneath requesting conditions.

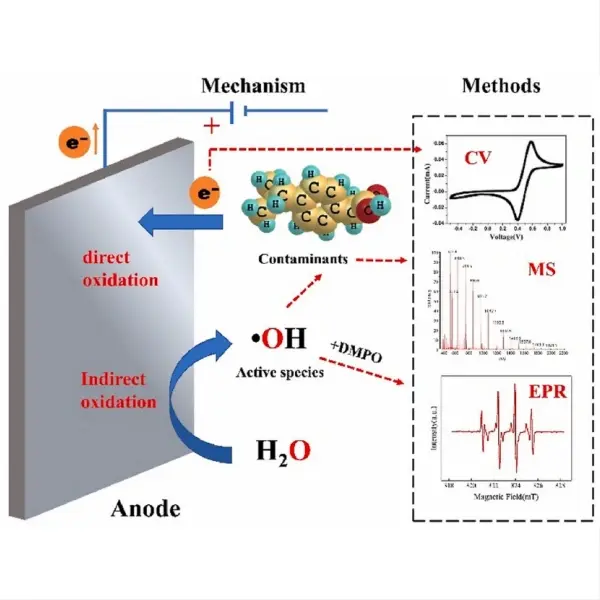

Catalytic Properties: Ruthenium and iridium coatings bestow catalytic action to the anodes, encouraging vital electrochemical responses such as oxygen advancement, chlorine era, and natural compound oxidation, hence driving different mechanical forms.

Water Treatment: Ruthenium-iridium coated titanium anodes are widely utilized in electrochemical water treatment processes, including electrocoagulation, electrooxidation, and electrochlorination, enabling efficient removal of pollutants and disinfection of water in diverse applications.

Metal Electrowinning: Industries engaged in metal electrowinning, such as copper, zinc, and nickel production, benefit from the use of these anodes, which contribute to improved current distribution and energy efficiency during the electrodeposition of metals.

Electrolytic Chemical Generation: The anodes play a basic part in the electrolytic generation of chemicals, counting sodium chlorate and sodium hypochlorite, advertising cost-effective and naturally inviting implies of synthesizing vital chemical compounds.

Advancements in Coating Technology: Ongoing advancements in the development of ruthenium-iridium coatings on titanium anodes aim to optimize their performance, longevity, and cost-effectiveness, further expanding their potential for industrial applications.

Innovation at Its Core: How These Anodes Are Changing the Game

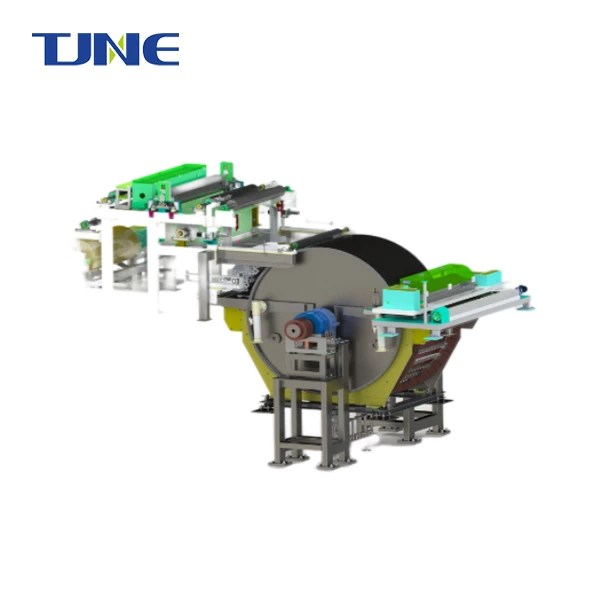

In the realm of industrial electrochemistry, the quest for more efficient and durable anode materials has long been a driving force behind innovation. In recent years, Ruthenium-Iridium coated Titanium Anodes have emerged as a game-changer, promising unparalleled performance and durability in a variety of applications. From electrolytic processes in metal refining to wastewater treatment and beyond, these advanced anodes are revolutionizing industries across the globe.

Beyond Durability: The Unique Benefits of Ruthenium-Iridium Coatings

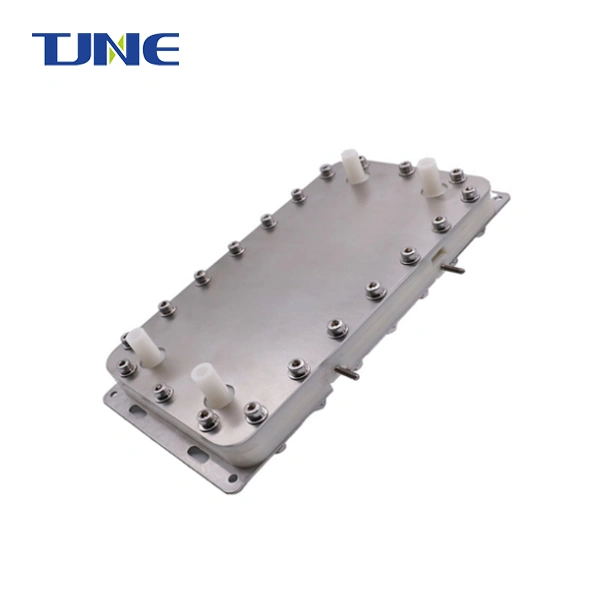

The key to the exceptional performance of Ruthenium Iridium coated Titanium Anodes lies in their unique composition. By depositing a thin layer of ruthenium and iridium onto a titanium substrate through advanced coating techniques, these anodes combine the corrosion resistance of titanium with the catalytic properties of ruthenium and iridium. The result is an electrode material that excels in harsh environments, where traditional materials falter.

One of the most significant advantages of Ruthenium-Iridium coated Titanium Anodes is their exceptional durability. Unlike conventional materials like graphite or lead, which degrade over time due to corrosion or chemical attack, these coated titanium anodes exhibit outstanding resistance to corrosion, ensuring long-term stability and reliability in demanding industrial processes.

Moreover, the catalytic properties of ruthenium and iridium enable enhanced electrochemical reactions, leading to higher efficiency and productivity. Whether used in electroplating, water disinfection, or chlor-alkali electrolysis, Ruthenium-Iridium coated Titanium Anodes facilitate faster reaction rates and lower energy consumption, resulting in significant cost savings for industrial operators.

From the Lab to the Field: Real-World Success Stories

The real-world impact of Ruthenium Iridium coated Titanium Anodes is evident in numerous success stories across various industries. In the field of metal refining, for instance, these advanced anodes have enabled significant improvements in the efficiency and purity of electroplating processes, leading to higher-quality end products and reduced waste.

Similarly, in the realm of wastewater treatment, Ruthenium-Iridium coated Titanium Anodes have proven instrumental in achieving stringent regulatory standards for water quality. By facilitating the oxidation of organic pollutants and the disinfection of pathogens, these anodes help municipalities and industrial facilities alike to meet environmental compliance requirements effectively.

Sustainability and Efficiency: The Environmental Impact of Advanced Anode Technology

In addition to their performance benefits, Ruthenium-Iridium coated Titanium Anodes offer compelling advantages in terms of sustainability and environmental impact. By minimizing the consumption of chemicals and energy in electrochemical processes, these anodes contribute to overall resource efficiency and reduce the environmental footprint of industrial operations.

Furthermore, the longevity of Ruthenium-Iridium coated Titanium Anodes translates to reduced waste generation and lower maintenance requirements, further enhancing their sustainability credentials. Unlike disposable anode materials that contribute to landfill waste, these durable electrodes can withstand years of continuous use, providing lasting value to operators while minimizing environmental harm.

Conclusion

In conclusion, Ruthenium Iridium coated Titanium Anodes represent a significant advancement in electrochemical technology, offering unmatched durability, efficiency, and sustainability in a wide range of industrial applications. As industries strive to optimize their processes and minimize their environmental impact, these advanced anodes are poised to play a pivotal role in driving progress towards a more sustainable future.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of Ruthenium Iridium coated Titanium Anodes, welcome to contact us: yangbo@tjanode.com

References

1. Comninellis, C. (2005). Electrocatalysis in the Electrochemical Conversion/Storage of Energy. Electrochimica Acta, 50(20), 4174-4183. https://doi.org/10.1016/j.electacta.2005.02.012

2. Pletcher, D., & Walsh, F. C. (1999). Industrial Electrochemistry. Springer Science & Business Media.

3. Rajeshwar, K., & Ibanez, J. G. (2016). Environmental Electrochemistry: Fundamentals and Applications in Pollution Abatement. Academic Press.

4. Cherevatskaya, M., & Macounová, K. (2021). Electrochemical Water Treatment as a Basis for Sustainable and Efficient Technologies. ChemEngineering, 5(6), 81. https://doi.org/10.3390/chemengineering5060081

5. Hoshi, N., & Ueda, T. (2000). Environmental Electrochemistry: Methods and Applications. Academic Press.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- The Power of Splitting Water: An In-Depth Look at Alkaline Water Electrolyzers

- How Can an Electrodeposited Titanium Electrode Improve Nickel-Cobalt Battery Performance?

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- What Makes PCB RPP Copper Plating Essential for Durable Surface Area Enhancement?

- How Does Gold Plating Enhance PCB Performance? An In-Depth Exploration

- How Does PCB VCP DC Copper Plating Work in Direct Current Systems?

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?