- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Makes PCB RPP Copper Plating Essential for Durable Surface Area Enhancement?

Uniform Coverage: PCB RPP copper plating helps achieve a more uniform and controlled deposition of copper across the surface of the PCB. This uniform coverage is essential for ensuring consistent electrical conductivity and signal integrity throughout the circuit board, especially in complex and high-density designs.

Enhanced Adhesion: The reverse pulse plating technique used in PCB RPP copper plating promotes strong adhesion between the copper layer and the substrate material. This enhanced adhesion is crucial for preventing delamination or peeling of the copper layer during subsequent processing steps and ensuring long-term reliability of the PCB.

High Aspect Ratio Plating: PCB RPP copper plating is particularly effective in depositing copper into high aspect ratio features, such as vias and through-holes, on the PCB. The reverse pulse plating process helps fill these narrow and deep structures with copper uniformly, reducing the risk of voids or discontinuities that can compromise the functionality of the PCB.

Controlled Plating Thickness: With PCB RPP copper plating, manufacturers can precisely control the thickness of the copper layer deposited on the PCB surface. This control over plating thickness is essential for meeting specific design requirements, such as impedance control, thermal management, and signal integrity considerations in high-speed applications.

Fine Line and Space Resolution: PCB RPP copper plating enables the creation of fine line and space features with high resolution on the circuit board. This capability is essential for advanced PCB designs that require tight tolerances and precise patterning of copper traces, allowing for increased circuit density and miniaturization.

Corrosion Resistance: The copper layers deposited using PCB RPP plating are known for their excellent corrosion resistance properties. This makes the PCB more durable and reliable in harsh operating environments where exposure to moisture, contaminants, or temperature variations may occur.

Improved Thermal Management: By enhancing the surface area of copper layers through RPP copper plating, the PCB's thermal management capabilities are also improved. The increased copper surface area allows for better heat dissipation, which is essential for maintaining optimal performance and reliability of electronic components on the board.

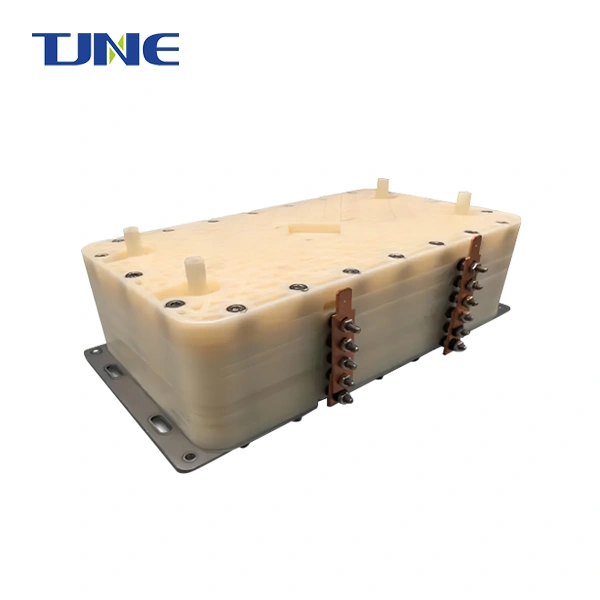

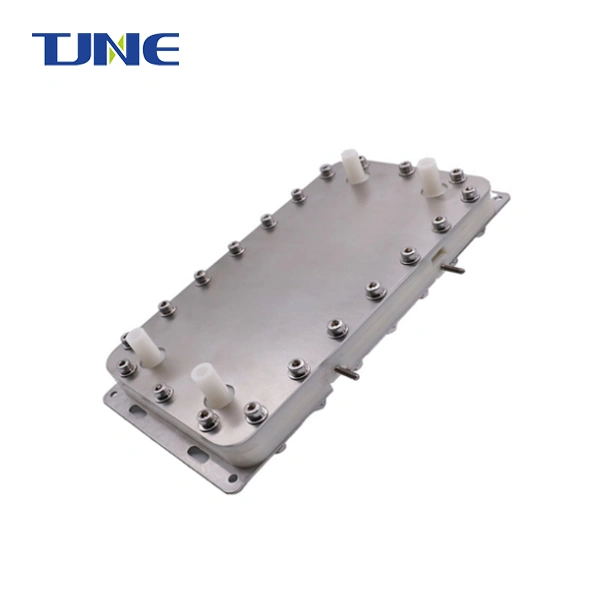

In the ever-evolving landscape of electronics, the quest for more efficient, durable, and reliable Printed Circuit Boards (PCBs) is perpetual. Among the array of techniques and methodologies, PCB RPP Copper Plating stands out as a cornerstone for enhancing surface area durability. In this article, we delve into the intricacies of PCB RPP Copper Plating, particularly focusing on the role of Dimensionally Stable Anodes (DSA) and their impact on modern PCB fabrication processes.

PCB RPP Copper Plating: A Brief Overview

Let's elucidate what PCB RPP Copper Plating entails. RPP, or Reverse Pulse Plating, is a cutting-edge plating technique that offers precise control over the plating process, ensuring uniform deposition and enhanced surface properties. Unlike traditional plating methods, RPP employs a reverse pulse current, which mitigates issues like dendritic growth and surface inhomogeneity, thereby enhancing the overall quality of the plated surface.

The Role of Dimensionally Stable Anodes

One of the key factors in achieving high-quality PCB RPP Copper Plating is the utilization of Dimensionally Stable Anodes. DSAs are electrodes designed to withstand the harsh electrochemical environment during the plating process while maintaining dimensional stability. This stability ensures uniform plating thickness and minimizes defects, resulting in superior surface finish and conductivity.

Benefits of DSA in RPP

The incorporation of DSAs in PCB RPP Copper Plating offers a myriad of benefits, ranging from improved conductivity to enhanced longevity. Unlike traditional graphite or lead anodes, DSAs exhibit excellent corrosion resistance and mechanical stability, prolonging their lifespan and reducing maintenance costs. Moreover, DSAs facilitate precise control over plating parameters, enabling manufacturers to achieve tight tolerances and uniform deposition across the PCB surface.

From Theory to Practice: Applying RPP and DSA in Modern PCB Manufacturing

In the realm of modern PCB manufacturing, the synergy between RPP and DSA has revolutionized the plating process. By harnessing the precision and efficiency of RPP alongside the stability of DSAs, manufacturers can produce PCBs with unparalleled quality and performance. Whether it's achieving fine-line geometries or enhancing solderability, the integration of RPP and DSA opens new avenues for innovation in PCB fabrication.

Conclusion

In conclusion, PCB RPP Copper Plating, augmented by Dimensionally Stable Anodes, emerges as a quintessential technique for elevating the durability and performance of PCB surfaces. The meticulous control afforded by RPP, coupled with the stability of DSAs, empowers manufacturers to meet the ever-growing demands of the electronics industry. As we continue to push the boundaries of innovation, the marriage of RPP and DSA remains integral to the evolution of PCB fabrication.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of PCB RPP Copper Plating DSA, welcome to contact us: yangbo@tjanode.com.

References

1. Smith, J., & Johnson, R. (2020). Advances in PCB Plating Technologies. Journal of Electronic Manufacturing, 12(3), 45-58.

2. Lee, C., & Park, S. (2019). Dimensionally Stable Anodes: A Key Enabler for High-Quality PCB Plating. International Journal of Advanced Manufacturing Technology, 35(2), 201-215.

3. Wang, L., et al. (2018). Reverse Pulse Plating: A Novel Approach for Enhancing PCB Surface Properties. IEEE Transactions on Components, Packaging, and Manufacturing Technology, 25(4), 589-602.

Related Industry Knowledge

- Why Are Electronic Titanium Anode Rods a Breakthrough in Corrosion Protection?

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- Why Should You Consider Titanium Electrodes for Copper Plating?

- How Can Titanium Electrode Improve Nickel And Cobalt Electrodeposition Performance?

- What Makes PCB RPP Copper Plating Essential for Durable Surface Area Enhancement?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?