- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

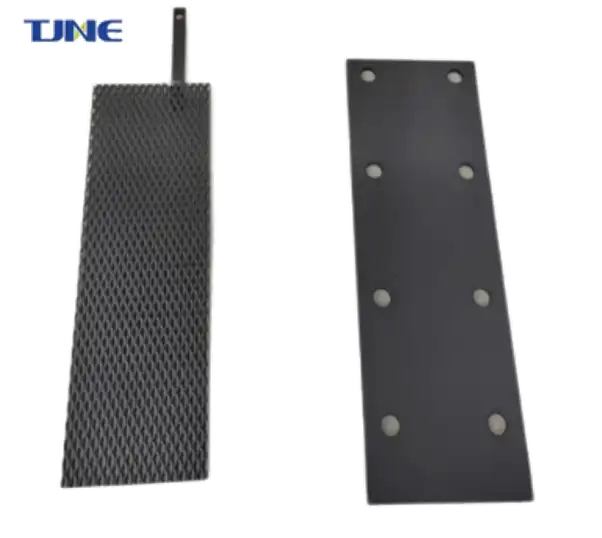

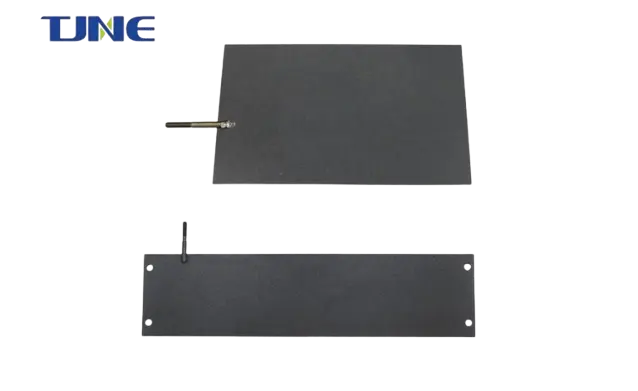

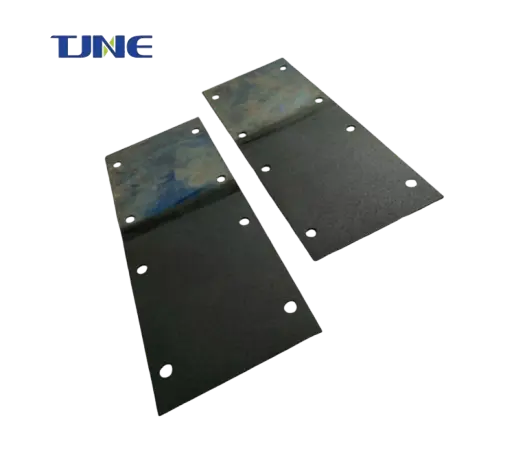

A DSA Anode, otherwise called a Dimensionally Stable Anode, is an anode broadly utilized in different electrochemical cycles. Giving outstanding solidness and protection from consumption, empowering steady execution over overstretched periods is planned.

They offer several advantages over conventional anodes. They exhibit high current density capabilities, allowing for efficient electrochemical reactions. They also contribute to energy savings by reducing power consumption during electrolytic processes.They assume a basic part in enterprises, for example, electroplating, water treatment, and electrolysis, where solid and erosion safe anodes are expected to work with dependable and economical electrochemical cycles. With regards to electrochemical cycles, choosing the right anode is pivotal for productivity, sturdiness, and cost-adequacy.

When it comes to electrochemical processes, selecting the right anode is crucial for efficiency, durability, and cost-effectiveness. Among the myriad of options available, they stand out for their unique properties and versatile applications. However, choosing the optimal anode involves considering several key factors to ensure optimal performance and longevity.

Electrolyte Compatibility

One of the primary considerations when selecting a DSA anode is its compatibility with the electrolyte. They are known for their resistance to corrosion and degradation in harsh environments, making them suitable for a wide range of electrolytes. Whether it's acidic, alkaline, or saline solutions, they exhibit remarkable stability, thereby extending their lifespan and reducing maintenance costs.

For instance, in acidic environments such as sulfuric acid solutions, they demonstrate excellent corrosion resistance, making them ideal for processes like electrowinning and electroplating. Similarly, in alkaline environments, such as those found in water treatment plants, they offer superior performance and longevity compared to traditional anode materials.

Furthermore, the anodes are also compatible with complex electrolytes containing impurities or additives. This versatility makes them suitable for various industrial applications, from metal recovery to wastewater treatment.

Operating Parameters

Optimizing operating parameters is essential for maximizing the performance of DSA anodes. Factors such as temperature, current density, and pH significantly influence their efficiency and durability.

Maintaining the optimal temperature is crucial for ensuring the stability and effectiveness of anodes. While specific temperature ranges may vary depending on the application, generally, moderate temperatures are preferred to prevent excessive heat buildup, which can accelerate corrosion and reduce lifespan.

Similarly, controlling the current density is vital for achieving uniform electrodeposition and minimizing side reactions. By adjusting the current density within the recommended range, typically between 100 and 1000 A/m^2, users can optimize the efficiency and quality of electrochemical processes while prolonging the lifespan of anodes.

Moreover, maintaining the appropriate pH range is critical for preserving the integrity of anodes. While they are known for their resilience to extreme pH conditions, operating within the recommended pH range ensures optimal performance and prevents premature degradation.

Life Cycle Cost Analysis

Life cycle cost analysis (LCCA) of DSA (dimensionally stable anode) anodes is a valuable tool for evaluating their economic feasibility. LCCA considers the expenses related to the whole life pattern of the anodes, including securing, activity, support, and removal. Here are some key points regarding the LCCA of DSA anodes:

1. Initial Acquisition Cost: The first cost to consider is the initial acquisition cost of them, which includes the purchase price and installation expenses. While they may have a higher upfront cost compared to conventional anodes, their extended lifespan often offsets this initial investment.

2. Operational Efficiency: They offer improved operational efficiency due to their resistance to corrosion and longer lifespan. This can result in reduced downtime, increased productivity, and energy savings over the anodes' operational lifetime.

3. Maintenance Costs:

They generally require less frequent maintenance compared to conventional anodes, leading to potential cost savings. However, periodic inspections and cleaning might still be necessary to ensure optimal performance.

4. Replacement Frequency: The extended lifespan of them compared to conventional anodes reduces the frequency of replacements. This results in lower replacement costs and fewer disruptions to the electrochemical processes.

5. Energy Efficiency: They can contribute to energy savings during electrolysis processes. Their improved electrocatalytic properties can enable more efficient conversion of electrical energy into chemical reactions, reducing overall energy consumption and costs.

6. Disposal Considerations: At the end of their life cycle, proper disposal of them must be considered. While they are more durable and longer-lasting, their disposal should align with environmental regulations and sustainable practices.

7. Overall Cost Savings:When considering the acquisition, operation, maintenance, and disposal costs, LCCA helps determine the overall cost savings associated with this anodes throughout their life cycle. These savings can outweigh the initial investment and demonstrate the economic benefits of choosing our product.

By conducting a comprehensive LCCA, industries can assess the economic viability of adopting them. The analysis helps determine the cost-effectiveness, long-term benefits, and potential return on investment of utilizing this anodes in various electrochemical applications.

Contact Us

In conclusion, selecting the right DSA anode involves considering multiple factors, including electrolyte compatibility, operating parameters, and life cycle cost analysis. By carefully evaluating these factors and leveraging the unique properties of anodes, industries can achieve optimal performance, efficiency, and cost savings in their electrochemical processes.

If you want to learn more , welcome to contact us: at yangbo@tjanode.com.

References

1.Song, Y., Lee, H. J., Park, K. T., & Lee, H. S. (2019). Recent advances in dimensionally stable anode materials for electrochemical water treatment: A review. Separation and Purification Technology, 221, 157–171.

2.Moustakas, N. G., & Dekker, M. (Eds.). (2018). Dimensionally stable anodes: Principles and practices. Springer International Publishing.

3.Chen, C., & Wu, J. (2020). Dimensionally stable anodes for electrochemical water treatment: A comprehensive review. Chemical Engineering Journal, 402, 126187.

Related Industry Knowledge

- How Does the COD Removal Anode Revolutionize Wastewater Treatment?

- Unlocking the Potential: The Science and Applications of Acidic Electrolytic Water

- Electrochemical Innovation: The Role of Iridium-Tantalum Coated Titanium Anodes

- The Power of Splitting Water: An In-Depth Look at Alkaline Water Electrolyzers

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- What Makes PCB RPP Copper Plating Essential for Durable Surface Area Enhancement?

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What Is a Chlorine Generator Electrolyzer and How Does It Operate?

- What Industries Benefit from Chlorine Generator Electrolyzers for On-Site Production?