- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

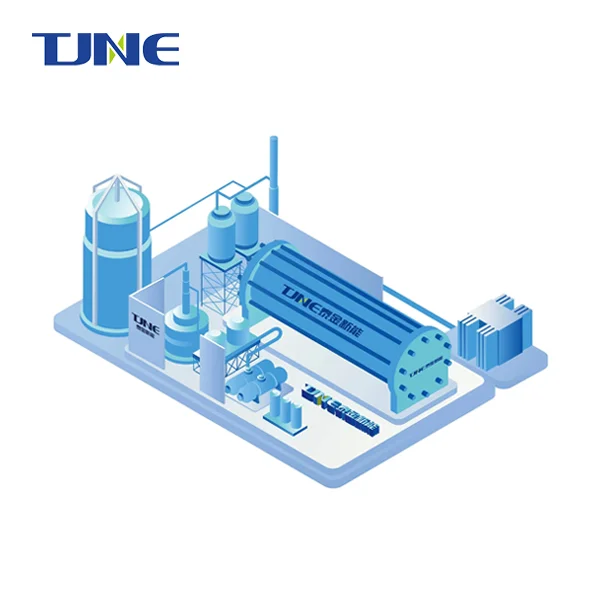

Our company have witnessed the pivotal role that MMO anode plates play in safeguarding critical infrastructure across multiple industries. Let's delve into how these innovative anode plates are utilized in the marine industry, pipeline protection, and storage tank maintenance to combat corrosion effectively.

1. Marine Industry: Preserving Offshore Structures and Ships

The marine industry faces relentless corrosion challenges due to the harsh and corrosive marine environment. Offshore structures and ships are particularly vulnerable to corrosion, threatening their structural integrity and operational efficiency. MMO anode plates offer a robust solution by providing cathodic protection to these assets.

In offshore applications, they are strategically installed on the submerged surfaces of platforms, pipelines, and other offshore structures. These anode plates operate sacrificially, corroding instead of the protected structure, thus extending its service life.

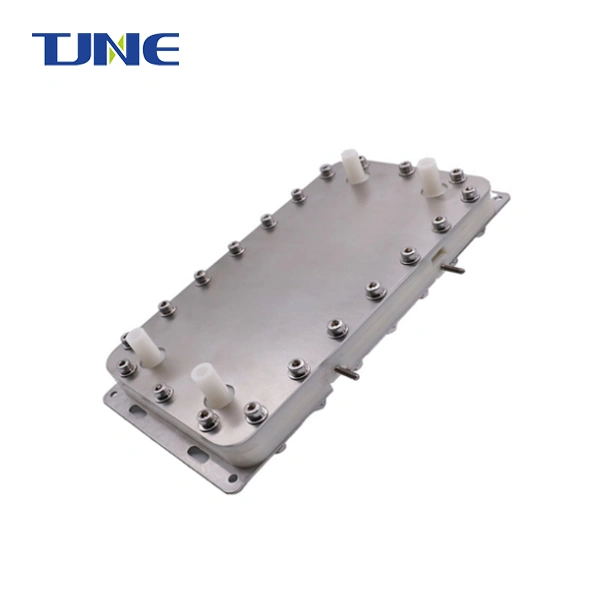

Moreover, the anode plates ensure uniform current distribution, effectively mitigating localized corrosion and enhancing overall protection efficiency.

Similarly, in ship hulls, they are installed to prevent corrosion-induced damage. By forming an electrochemical barrier, these anodes inhibit the oxidation process on the metal surface, thereby preserving the integrity of the vessel's hull. This proactive approach not only reduces maintenance costs but also enhances safety by preventing catastrophic failures.

2. Pipeline Protection: Safeguarding Underground Infrastructure

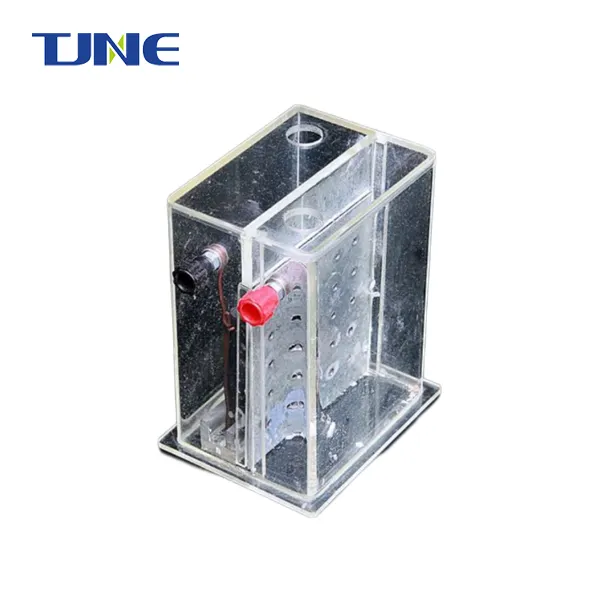

MMO anode plates are commonly used for cathodic protection in underground pipelines, providing a reliable and cost-effective solution to safeguarding critical infrastructure against corrosion. Cathodic protection is a technique used to prevent corrosion by making the metal structure the cathode of an electrochemical cell. In this process, these anode plates are employed as the anode, delivering electrical current to the pipeline to neutralize the corrosive potential.

To ensure effective pipeline protection, these anode plates are installed along with reference electrodes that monitor the pipeline's potential and provide feedback to the power supply unit. These anode plates are typically installed in a grid pattern around the pipeline, creating a protective current field that reduces the likelihood of corrosion.

The corrosion resistance of the anode plates makes them ideal for use in aggressive soil environments, where other types of anodes may degrade quickly. The mixed metal oxide coating on the anode plates forms a passive film, preventing corrosive reactions and enhancing the overall corrosion resistance of the anode plates.

These anode plates can also withstand high temperatures without compromising their protective properties, making them suitable for use in pipelines carrying hot fluids or gases. In addition, the anode plates exhibit excellent acid resistance, protecting the pipeline from acidic soils and other corrosive substances.

Overall, the anode plates are a proven solution for pipeline protection, offering long-term performance and low maintenance requirements. Their exceptional corrosion resistance and durability make them an excellent choice for safeguarding underground infrastructure and ensuring the integrity of critical assets. With the use of our anode plates for cathodic protection, pipelines, and other underground structures can be protected from corrosion and remain operational for extended periods, contributing to the safety and sustainability of our communities.

3. Storage Tank Maintenance: Enhancing Cathodic Protection

Storage tanks play a crucial role in various industries, including oil and gas, petrochemicals, and water treatment. However, they are susceptible to corrosion both internally and externally, jeopardizing the integrity of stored contents and posing environmental risks. MMO anode plates offer an efficient solution for mitigating corrosion in storage tank systems.

Installed within the tank's interior or externally on its surface, the anode plates generate a protective current that inhibits corrosion on the tank's metal surfaces. By maintaining the tank's structure in a passive state, these anodes prevent the formation of rust and other corrosion by-products, thereby prolonging the tank's service life and ensuring the integrity of stored contents.

Moreover, they can be tailored to suit specific tank geometries and operating conditions, ensuring optimal performance and compatibility with existing cathodic protection systems. This versatility makes the anode plates a preferred choice for storage tank maintenance across various industries, where reliability and durability are paramount.

Contact Us

In conclusion, MMO anode plates play a pivotal role in corrosion protection and cathodic protection across diverse industries. From offshore structures and ships to underground pipelines and storage tanks, these innovative anodes offer a reliable and cost-effective solution for safeguarding critical infrastructure against corrosion-induced damage. By embracing proactive corrosion mitigation strategies, industries can enhance asset longevity, minimize downtime, and ensure operational safety and efficiency.

If you want to learn more about anode plates, welcome to contact us: yangbo@tjanode.com.

References

1.Mansfeld, Florian, and Kenneth S. Coley. "Cathodic protection of steel in concrete using MMO anode technology." Materials and Corrosion 55.4 (2004): 295-301.

2.Melchers, Robert E. "Corrosion of MMO anodes for impressed current cathodic protection of steel in concrete." Corrosion Science 46.11 (2004): 2729-2745.

3.NACE International. "Standard Recommended Practice: Application, Performance, and Monitoring of Impressed Current Deep Groundbeds." NACE International RP0177-2000 (2000).

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- How Do Anodes Facilitate the Removal of Ammonia Nitrogen from Water?

- How Does the COD Removal Anode Revolutionize Wastewater Treatment?

- Unlocking the Potential: The Science and Applications of Acidic Electrolytic Water

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- How Does Gold Plating Enhance PCB Performance? An In-Depth Exploration

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- Which electrolyzer is best for hydrogen production?