- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

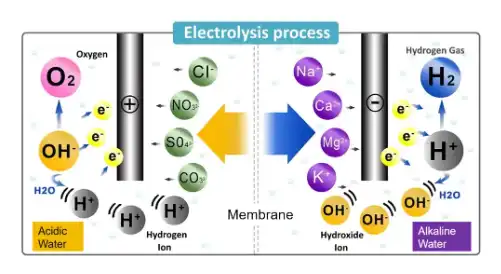

Electrolysis Prepare: Alkaline Water Electrolyser includes passing an electric current through water, which contains broken up electrolytes, to encourage the division of hydrogen and oxygen. The prepare takes put inside an electrolysis cell containing an anode (positive cathode) and a cathode (negative cathode), which are isolated by an electrolyte solution.

Alkaline Electrolyzers: Alkaline water electrolyzers utilize an soluble electrolyte, ordinarily potassium hydroxide (KOH), to improve the conductivity of the water and advance the electrolysis prepare. The utilize of antacid electrolytes permits for productive hydrogen generation at moderately moo temperatures and pressures.

Hydrogen Generation: The essential yield of soluble water electrolysis is atomic hydrogen (H2) gas, which can serve as a clean and economical vitality carrier. Hydrogen created through this strategy has potential applications in fuel cells, mechanical forms, vitality capacity, and transportation.

Benefits of Alkaline Water Electrolysis

Renewable Vitality Source: Antacid water electrolysis empowers the era of hydrogen gas from water utilizing power inferred from renewable sources such as sun oriented or wind power.

Clean Vitality Generation: The coming about hydrogen can be utilized as a clean-burning fuel without creating nursery gas emanations or discuss poisons when expended in fuel cells or other hydrogen-powered devices.

Scalability: Antacid water electrolyzers can be planned in different scales, extending from small-scale frameworks for investigate and experimentation to expansive mechanical units for commercial hydrogen generation.

Challenges and Considerations

Vitality Productivity: Progressing the vitality productivity of Alkaline Water Electrolyser remains an region of center to diminish the by and large taken a toll of hydrogen production.

Material Choice: The choice of anode materials and electrolyte compositions is vital for accomplishing long-term soundness, strength, and cost-effectiveness in electrolyzer operation.

Cost Competitiveness: Proceeded investigate and improvement are pointed at lessening the capital and operational costs related with antacid water electrolysis to make hydrogen generation financially competitive with conventional strategies.

As an enthusiast in the field of sustainable energy, delving into the realm of alkaline water electrolyzers has been an enlightening journey. These devices, which harness the power of splitting water into hydrogen and oxygen, hold immense promise in shaping our future energy landscape.

How Alkaline Water Electrolyzers Work: The Science of Hydrogen Production

At the heart of every alkaline water electrolyzer lies a fundamental principle: electrolysis. This process involves the decomposition of water into its constituent elements, hydrogen, and oxygen, through the application of an electric current. The electrolyzer comprises two electrodes, an anode, and a cathode, separated by an electrolyte solution.

When an electric current is passed through the electrolyte solution, water molecules near the anode undergo oxidation, releasing oxygen gas and positively charged hydrogen ions (protons). Meanwhile, at the cathode, hydrogen ions are reduced, forming hydrogen gas. This simultaneous oxidation and reduction reactions result in the separation of water into its elemental components.

The Benefits of Alkaline Electrolysis: Efficiency, Economy, and Environment

Alkaline water electrolyzers offer a multitude of advantages that make them an attractive choice for hydrogen production. Firstly, they exhibit high efficiency, converting electrical energy into hydrogen with minimal energy losses. This efficiency is further complemented by the economic viability of alkaline electrolysis, owing to the use of relatively inexpensive materials such as nickel and potassium hydroxide (KOH).

Moreover, the environmental credentials of alkaline water electrolyzers cannot be overlooked. Unlike traditional methods of hydrogen production, such as steam methane reforming, alkaline electrolysis produces hydrogen without emitting greenhouse gases. This makes it a sustainable and environmentally friendly solution for hydrogen generation, aligning with global efforts to combat climate change.

Key Components and Materials: Inside the World of Alkaline Electrolyzers

A closer examination of alkaline water electrolyzers reveals the intricate interplay of various components and materials. The electrodes, typically composed of nickel or nickel-plated materials, serve as catalysts for the electrolysis reactions. The electrolyte, commonly potassium hydroxide solution, facilitates the conduction of ions between the electrodes.

Additionally, advanced alkaline electrolyzer designs incorporate innovative features such as porous electrode structures and efficient gas separation membranes. These enhancements enhance performance and durability, ensuring reliable operation over extended periods.

Challenges and Solutions: Advancing the Frontiers of Alkaline Water Electrolysis

Despite their numerous benefits, alkaline water electrolyzers face certain challenges that impede widespread adoption. One such challenge is the alkaline electrolyte's susceptibility to degradation over time, necessitating regular maintenance and replacement. However, ongoing research efforts are focused on developing robust electrolyte formulations and electrode materials to mitigate these issues.

Furthermore, the scalability of alkaline electrolysis systems remains an area of active research, with endeavors aimed at enhancing production capacities and reducing capital costs. Collaborative initiatives between academia, industry, and government agencies play a pivotal role in driving innovation and overcoming technological barriers.

Conclusion

In conclusion, alkaline water electrolyzers represent a cornerstone of sustainable hydrogen production, offering efficiency, affordability, and environmental sustainability. As we strive towards a carbon-neutral future, the role of alkaline electrolysis in facilitating the transition to a hydrogen-based economy cannot be overstated.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of Alkaline Water Electrolyser, welcome to contact us: yangbo@tjanode.com.

References

1. Larminie, J., & Dicks, A. (2003). Fuel cell systems explained. John Wiley & Sons.

2. Zeng, K., & Zhang, D. (2010). Recent progress in alkaline water electrolysis for hydrogen production and applications. Progress in Energy and Combustion Science, 36(3), 307-326.

3. Carmo, M., Fritz, D. L., Mergel, J., & Stolten, D. (2013). A comprehensive review on PEM water electrolysis. International Journal of Hydrogen Energy, 38(12), 4901-4934.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- How Can Titanium Electrode Improve Nickel And Cobalt Electrodeposition Performance?

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What Industries Benefit from Chlorine Generator Electrolyzers for On-Site Production?

- What are DSA anodes?