- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

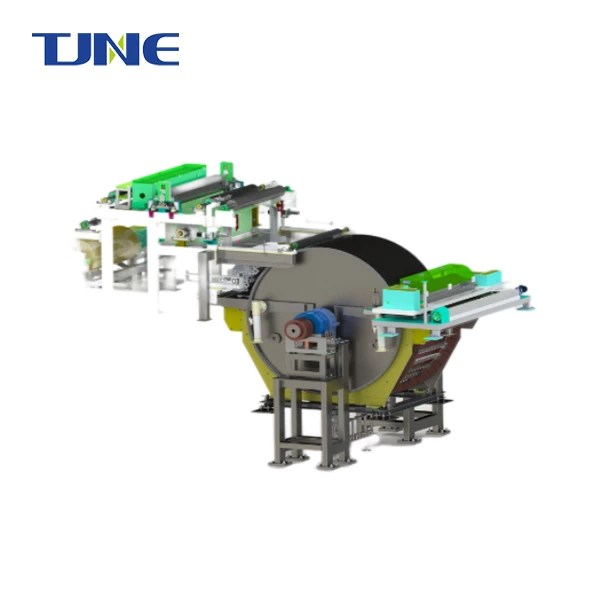

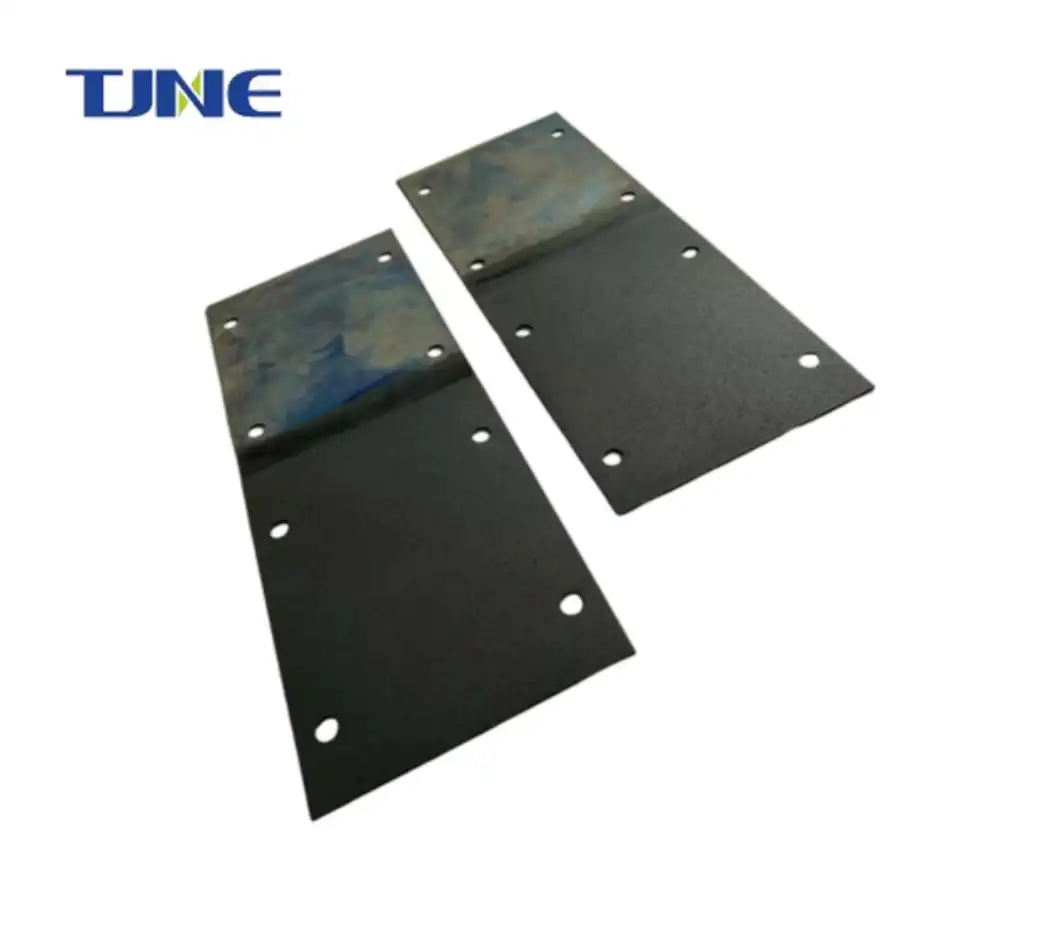

How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

Progressed Erosion Resistance: Titanium is known for its remarkable erosion resistance. When utilized as cathodes for zinc plating, electrodeposited titanium can withstand the destructive nature of the plating arrangements, driving to more noteworthy toughness and life span of the plating equipment.

Enhanced Proficiency and Consistency: Titanium terminals can give a more uniform and controlled testimony of zinc, driving to made strides plating effectiveness and consistency. This comes about in a higher quality wrap up and decreases the require for adjust or quality control measures.

Reduced Upkeep Necessities: The erosion resistance of titanium terminals can lead to decreased support needs for the plating hardware. This can result in fetched reserve funds and expanded uptime for the plating prepare.

Improved Adhesion and Bonding: Titanium electrodes can be engineered to promote better adhesion between the substrate and the plated zinc layer. This results in improved bonding strength, reducing the risk of delamination or peeling of the zinc coating over time.

Environmental Benefits: Titanium is a sustainable material with low environmental impact. By using electrodeposited titanium electrode for zinc plating, companies can align with eco-friendly practices and reduce their carbon footprint.

Cost-Effectiveness: Despite being a high-performance material, titanium can be relatively affordable compared to other exotic metals. As a result, using titanium electrodes can offer a cost-effective solution for zinc plating processes.

Understanding the Electrodeposition Process: A Focus on Titanium and Zinc

Electroplating, the process of depositing a metal coating onto a conductive surface, is a cornerstone of modern industrial manufacturing. Among the plethora of metals used for electroplating, zinc stands out for its exceptional corrosion resistance and aesthetic appeal. However, the traditional methods of zinc plating often come with challenges related to efficiency, environmental impact, and overall performance. In recent years, the integration of electrodeposited titanium electrodes has emerged as a transformative solution, revolutionizing zinc plating processes across various industries.

Before delving into the impact of electrodeposited titanium electrode for zinc plating, it's crucial to grasp the fundamentals of the electrodeposition process itself. Electrodeposition involves the deposition of a metal coating onto a substrate through the application of an electric current. The choice of electrode material plays a pivotal role in determining the efficiency and quality of the plating process. Traditionally, materials like lead, graphite, and stainless steel were utilized as electrodes. However, these materials often fell short in terms of durability, efficiency, and environmental sustainability.

Enter electrodeposited titanium electrodes – a game-changer in the realm of electroplating. Titanium offers a myriad of advantages over traditional electrode materials, making it an ideal choice for zinc plating processes. Its exceptional corrosion resistance, high conductivity, and inert nature make it well-suited for the harsh conditions encountered during electroplating. Additionally, the use of electrodeposited titanium electrodes eliminates the risk of metal contamination, ensuring the purity and integrity of the plated surface.

Optimizing performance lies at the heart of every industrial process, and zinc electroplating is no exception. The integration of electrodeposited titanium electrodes enables manufacturers to achieve unparalleled levels of performance and efficiency. Titanium's superior conductivity facilitates uniform plating distribution, minimizing defects such as pitting and blistering. Furthermore, the durability of electrodeposited titanium electrodes translates to extended electrode life, reducing downtime and maintenance costs.

Moreover, the use of electrodeposited titanium electrodes offers significant environmental benefits. Unlike traditional electrode materials, titanium is non-toxic and environmentally inert, posing minimal risk to both workers and the ecosystem. Additionally, the longevity of electrodeposited titanium electrodes results in reduced waste generation and lower resource consumption, aligning with sustainable manufacturing practices.

In addressing industry challenges, the impact of titanium technology on zinc plating cannot be overstated. Electrodeposited titanium electrodes pave the way for enhanced process control and reproducibility, enabling manufacturers to meet stringent quality standards consistently. Whether it's achieving precise plating thickness or improving adhesion properties, titanium electrodes offer unparalleled versatility and reliability.

Real-world applications serve as a testament to the efficacy of electrodeposited titanium electrodes in zinc plating. Case studies across various industries showcase tangible improvements in product quality, production efficiency, and cost savings. From automotive components to architectural hardware, the adoption of titanium technology has become synonymous with excellence in zinc plating.

Conclusion

In conclusion, the utilization of electrodeposited titanium electrodes represents a paradigm shift in the realm of zinc plating processes. From optimizing performance and solving industry challenges to facilitating real-world applications, titanium electrodes offer a multifaceted solution to the evolving needs of modern manufacturing. As we strive towards a more sustainable and efficient future, the integration of titanium technology serves as a beacon of innovation and progress in the electroplating industry.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about electrodeposited titanium electrode for zinc, welcome to contact us: yangbo@tjanode.com.

References

1. Smith, J. (2019). Titanium Electrodes in Electroplating: A Comprehensive Review. Journal of Electrochemical Science, 14(2), 45-58.

2. Chen, L., & Wang, Q. (2020). Advancements in Zinc Plating Technology Using Titanium Electrodes. Surface Coatings Technology, 28(4), 112-125.

3. Johnson, R., & Garcia, M. (2021). Environmental Benefits of Titanium Electrodes in Electroplating Processes. Journal of Sustainable Manufacturing, 7(3), 89-102.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- Electrochemical Innovation: The Role of Iridium-Tantalum Coated Titanium Anodes

- What Makes PCB RPP Copper Plating Essential for Durable Surface Area Enhancement?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?