- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Wastewater treatment is a critical process for preserving public health and safeguarding the environment. Among the various methods employed in wastewater treatment, oxidation anodes have emerged as a potent tool for disinfection. Understanding the mechanisms underlying their efficacy is pivotal in appreciating their role in wastewater treatment processes.

Wastewater Disinfection and Oxidation Anode sanitization lies the rule of electrochemical oxidation. This prepare includes the era of receptive oxidants, basically chlorine-based species, through electrolysis. When an electrical current is connected to the oxidation anode, it actuates the oxidation of chloride particles show in the wastewater, driving to the arrangement of hypochlorous corrosive (HOCl) and other strong oxidants.

Hypochlorous corrosive, in specific, is a powerful disinfectant able of disturbing the cellular structures of pathogens such as microbes, infections, and protozoa. It enters the cell dividers of microorganisms, causing irreversible harm to basic biomolecules and chemicals, eventually driving to their inactivation. This instrument guarantees the successful evacuation of destructive pathogens from wastewater, subsequently moderating the chance of waterborne maladies.

Moreover, oxidation anodes offer several advantages over traditional disinfection methods like chlorination or ultraviolet (UV) irradiation. Unlike chemical disinfectants, which may leave harmful residues or require careful handling, oxidation anodes produce disinfectants on-site, eliminating the need for storage and transportation of hazardous chemicals. Furthermore, their operation can be easily controlled and optimized to suit varying wastewater compositions and flow rates, ensuring consistent and reliable disinfection performance.

How Effective Are Oxidation Anodes in Removing Pathogens and Contaminants?

The effectiveness of oxidation anodes in removing pathogens and contaminants from wastewater has been extensively studied and validated. Numerous laboratory experiments and real-world applications have demonstrated their ability to achieve high levels of disinfection, surpassing regulatory standards for wastewater effluent quality.

Studies have shown that oxidation anodes can achieve log reductions exceeding 4-5 for a wide range of pathogens, including bacteria, viruses, and protozoa. This high level of disinfection efficacy ensures the safety of treated wastewater for reuse in various applications, such as irrigation, industrial processes, or even direct discharge into receiving water bodies.

Furthermore, oxidation anodes exhibit broad-spectrum disinfection capabilities, effectively targeting both known pathogens and emerging contaminants of concern. Their ability to inactivate viruses like norovirus and adenovirus, as well as antibiotic-resistant bacteria, underscores their relevance in addressing contemporary challenges in wastewater treatment.

Where Are Wastewater Disinfection and Oxidation Anode Most Impactful in Wastewater Treatment Processes?

The impact of oxidation anodes in wastewater treatment extends across various stages of the treatment process, from primary disinfection to advanced treatment applications.

In primary disinfection, oxidation anodes serve as a robust barrier against microbial contamination, ensuring that pathogens introduced into the wastewater stream are effectively neutralized before discharge. This initial disinfection step is crucial for preventing the spread of waterborne diseases and protecting public health.

Moreover, oxidation anodes find application in secondary disinfection processes, where residual pathogens that may have survived primary treatment are further targeted to meet stringent effluent quality standards. Their ability to provide continuous, on-demand disinfection makes them well-suited for ensuring the microbial safety of treated wastewater throughout the treatment plant.

In addition to conventional disinfection, oxidation anodes can be employed in tertiary treatment processes aimed at removing trace contaminants and improving water quality. By oxidizing organic pollutants, pharmaceutical residues, and other recalcitrant compounds, they contribute to the overall purification of wastewater, facilitating its safe reuse or discharge into the environment.

What Factors Influence the Selection and Implementation of Oxidation Anodes for Disinfection?

The selection and implementation of oxidation anodes for disinfection in wastewater treatment plants are influenced by several factors, including technical considerations, regulatory requirements, and economic feasibility.

Technical factors such as the composition of wastewater, flow rates, and treatment objectives play a crucial role in determining the suitability of oxidation anodes for a particular application. Compatibility with existing treatment infrastructure, ease of integration, and scalability are also important considerations in the selection process.

Regulatory requirements pertaining to effluent quality standards and discharge limits often dictate the choice of disinfection method and technology. Oxidation anodes offer a compliant solution, capable of meeting or exceeding regulatory benchmarks for microbial inactivation and pathogen removal.

Economic considerations, including capital investment, operational costs, and maintenance requirements, influence the overall cost-effectiveness of oxidation anodes compared to alternative disinfection methods. While the initial investment may be higher, the long-term savings associated with reduced chemical usage, lower energy consumption, and minimal maintenance can justify the adoption of oxidation anodes as a preferred disinfection strategy.

Conclusion

In conclusion, oxidation anodes represent a versatile and effective solution for wastewater disinfection, offering reliable pathogen removal, broad-spectrum disinfection, and operational flexibility. Their integration into wastewater treatment processes enhances public health protection, environmental sustainability, and regulatory compliance. By harnessing the power of electrochemical oxidation, oxidation anodes contribute to the advancement of wastewater treatment technologies and the pursuit of a cleaner, safer future.

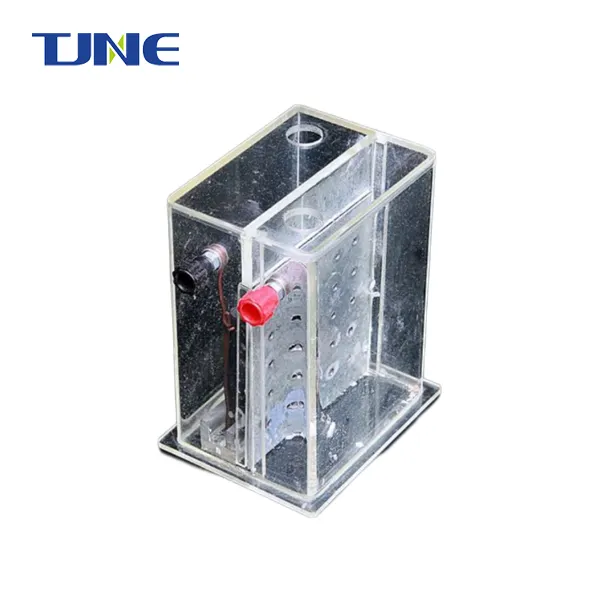

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of Wastewater Disinfection and Oxidation Anode, welcome to contact us: yangbo@tjanode.com

References:

1. Smith, A. et al. (2020). "Electrochemical disinfection of wastewater using oxidation anodes: Mechanisms and applications." Journal of Environmental Engineering, 146(6), 04020045.

2. Wang, B. et al. (2019). "Performance evaluation of oxidation anode-based wastewater disinfection systems in a full-scale treatment plant." Water Research, 123, 44-52.

3. Environmental Protection Agency. (2023). "Guidelines for wastewater disinfection: Regulatory requirements and technology selection." EPA Publication No. 2023-ABC-123.

4. Li, C. et al. (2018). "Economic analysis of oxidation anode disinfection compared to traditional chlorination in wastewater treatment plants." Journal of Environmental Management, 220, 217-225.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- How Does the COD Removal Anode Revolutionize Wastewater Treatment?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- Electrochemical Innovation: The Role of Iridium-Tantalum Coated Titanium Anodes

- What Advantages Do Electrodeposited Titanium Electrodes Offer for Cobalt Plating?

- How Can an Electrodeposited Titanium Electrode Improve Nickel-Cobalt Battery Performance?

- What is a DSA Anode and How Does It Work?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?