- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

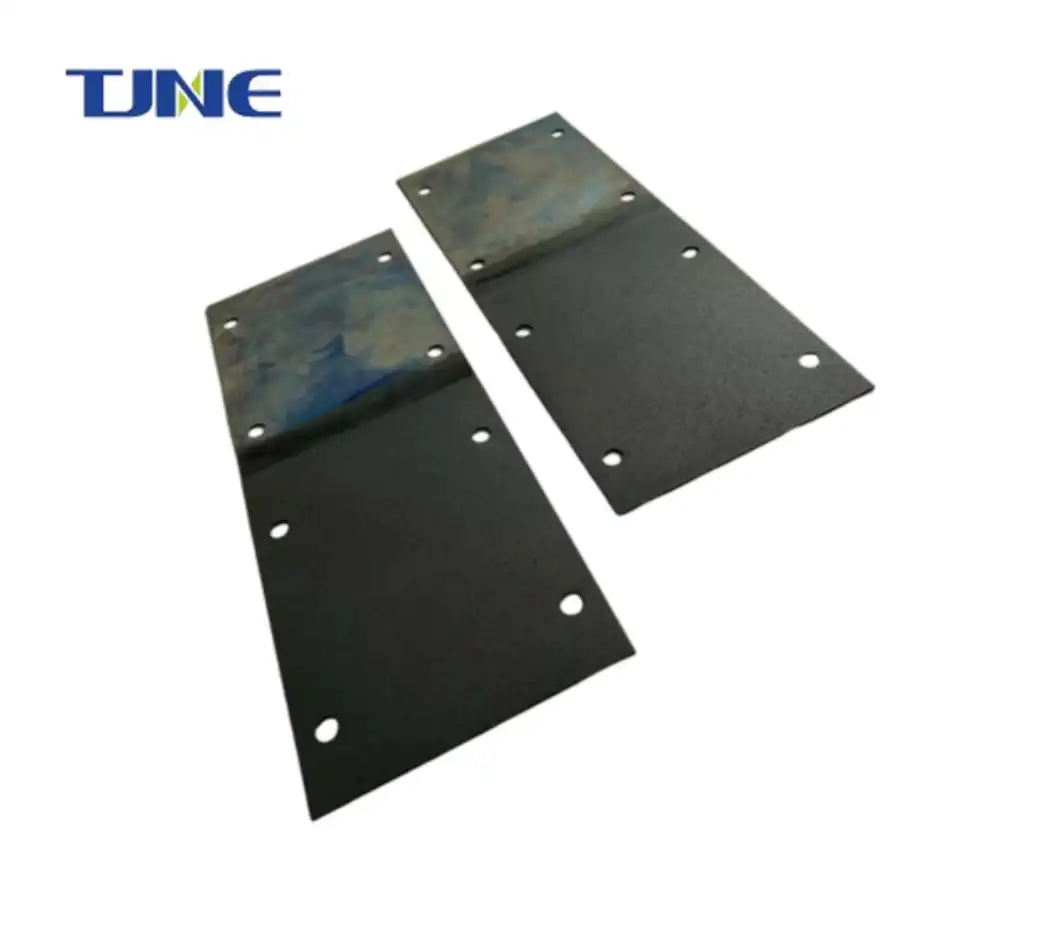

Ruthenium Iridium Coated Titanium Anodes

2.Material size: Available in various shapes and thickness to fit different industrial requirements, including plate in 1mm, 1.5mm, 2mm, and mesh in 1mm, 1.5mm, 2mm and more.

3.Coating: Coated with ruthenium iridium, with a service life more than 5 years. The chlorination potential is less than and equal to 1.1V and the current density is 2000A/m2.

4.Coating thickness: 0.2-20μm, easing the asked chemical responses and perfecting the overall effectiveness of the anode.

5.Application: Used for swimming pool disinfection, electrolytic water treatment, chlor-alkali industry, and appliance&electronics.

The ruthenium iridium coated titanium anodes offered by TJNE are renowned for their exceptional quality and versatility, making them a vital component in a range of industrial processes. These high-performance anodes are specifically designed to meet the diverse demands of various applications, providing reliable solutions in settings such as electrolysis and electrocatalysis. One of the standout features of these anodes is their availability in multiple shapes and sizes, suitable for different operational requirements. The construction of these anodes begins with a robust titanium substrate, which is known for its excellent mechanical strength and corrosion resistance. This substrate is then coated with a uniform layer of ruthenium and iridium, two precious metals recognized for their superior electrochemical properties.

- Available in different shape and size and able to work stably under constant current for a long time.

- Longer life than traditional anodes and significant energy saving effect

- Specially designed according to actual operating conditions to ensure that the best working results can be achieved under different media and uses.

| Item | Parameter |

|---|---|

| Substrate | GR1, GR2 |

| SUbstrate shape | Plate, mesh |

| Coating thickness | 0.2-20μm |

| Chlorine potential | ≤1.1V |

| Current effeciency | ≥95% |

| Operating temperature | Up to 60 °C |

| Max current density | 2000 A/m² |

Working Principle

The anodes work based on an oxidation-reduction reaction that occurs on the surface of the coated titanium substrate. The ruthenium and iridium coating acts as a catalyst, easing the asked chemical responses and perfecting the overall effectiveness of the anode.

Application

Swimming pool disinfection

The ruthenium iridium coated titanium anodes are designed to effectively disinfect the swimming pool in a safe, simple, and low-cost manner.

The titanium electrode works grounded on the electrolysis process. When the electrode is connected to a power source, the catalyst coating reacts with water to produce hypochlorous acid and sodium hypochlorite, which effectively kill bacteria, contagions, and other microorganisms that can pollute pool water.

Electrolytic water treatment

For electrolytic water treatment, ruthenium iridium coated titanium anodes enable robust and reliable performance in electro-oxidation processes for wastewater treatment, disinfection, and organic contaminant destruction. The anode offers an electrocatalytic activity for the oxygen evolution reaction, which generates reactive oxidants from water to oxidize pollutants. The electrodes also withstand harsh acidic conditions commonly used during electrolytic water treatment.

Chlor-alkali production

In chlor-alkali production, ruthenium iridium coated titanium anodes allow durable and efficient performance for the electrolysis of brine solutions to produce chlorine and sodium hydroxide. The anodes’electrocatalytic properties coupled with their corrosion resistance in harsh brine electrolytes make them well-suited to withstand aggressive chlor-alkali process conditions for a long time.

Appliance&electronics

Ruthenium iridium electrodes can also be used in household appliances by electrolyzing water for sterilization and disinfection, as well as changing the pH of water to produce acidic or alkaline water.

FAQ

How long does the coating last?

The expected lifespan of the coating is 5 to 8 years, depending on operating conditions.

Can the anodes be customized?

Yes, we offer customization services to meet specific requirements.

What certifications do your anodes have?

Our anodes are certified and comply with industry standards for quality and performance.

Contact us

TJNE is a professional manufacturer and supplier of ruthenium iridium coated titanium anodes. Our anodes are known for their excellent performance and durability. We offer comprehensive after-sales services, complete certification and testing reports, fast delivery, and secure packaging. If you are considering, feel free to contact us at yangbo@tjanode.com

YOU MAY LIKE