- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

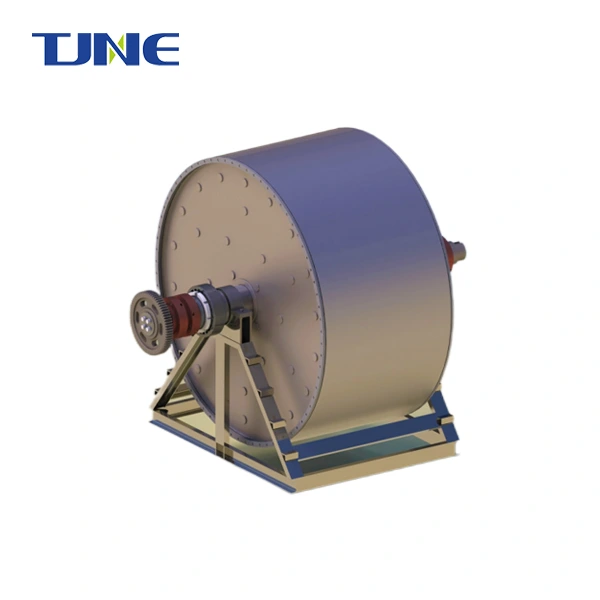

Ballast water management is a critical aspect of marine environmental protection, and the use of titanium electrodes has emerged as a key technology in this field. Titanium electrodes are specifically employed in ballast water treatment systems due to their unique properties that make them ideal for the harsh marine environment and the demanding requirements of ballast water disinfection. These electrodes play a crucial role in electrochemical treatment processes, which are among the most effective methods for eliminating harmful aquatic organisms and pathogens from ballast water.

How do titanium electrodes contribute to effective ballast water treatment?

Titanium electrodes are at the heart of electrochemical ballast water treatment systems, providing a powerful and efficient means of disinfecting water. The process typically involves electrolysis, where an electric current is passed through the ballast water via the titanium electrodes. This generates disinfecting agents directly from the seawater itself, primarily producing hypochlorite, which is a potent biocide.

The effectiveness of titanium electrodes in this application stems from several factors:

1. Corrosion Resistance: Titanium's exceptional resistance to corrosion in seawater environments is paramount. Unlike many other metals, titanium forms a stable, protective oxide layer when exposed to oxygen, making it highly resistant to the corrosive effects of saltwater. This property ensures the longevity of the electrodes, even under continuous exposure to seawater and the harsh chemicals produced during the electrolysis process.

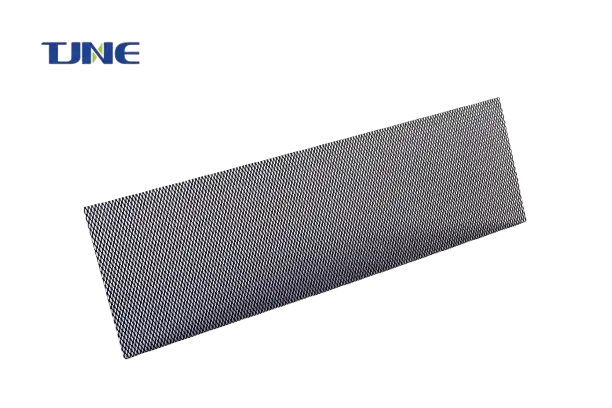

2. Conductivity: While not as conductive as some other metals like copper or silver, titanium offers a good balance of conductivity and corrosion resistance. When coated with specialized materials like mixed metal oxides (MMO), titanium electrodes can achieve excellent conductivity while maintaining their corrosion-resistant properties.

3. Durability: The strength and durability of titanium make it ideal for the demanding conditions within ballast water treatment systems. These electrodes can withstand the physical stresses of water flow and the chemical stresses of electrolysis without degrading or losing effectiveness over time.

4. Efficiency: Titanium electrodes, especially when coated with catalytic materials, can efficiently produce disinfecting agents at lower voltages compared to other electrode materials. This translates to lower energy consumption and more cost-effective operation of ballast water treatment systems.

5. Environmental Safety: Titanium is non-toxic and does not leach harmful substances into the water, aligning with the environmental goals of ballast water management. The use of titanium electrodes ensures that the treatment process itself does not introduce new contaminants into the marine ecosystem.

The combination of these properties makes titanium electrodes particularly well-suited for ballast water treatment. They enable the creation of robust, long-lasting, and efficient systems that can meet the stringent requirements of international ballast water management regulations, such as the International Maritime Organization's Ballast Water Management Convention.

What are the advantages of using titanium electrodes over other materials in ballast water systems?

When comparing titanium electrodes to other materials in ballast water treatment systems, several advantages become apparent, solidifying titanium's position as the material of choice for this application:

1. Superior Longevity: Titanium electrodes significantly outlast alternatives such as carbon, graphite, or even stainless steel in the corrosive seawater environment. This extended lifespan translates to reduced maintenance requirements and lower long-term operational costs for ship operators. While the initial investment in titanium electrodes may be higher, their durability often results in a lower total cost of ownership over the life of the treatment system.

2. Consistent Performance: Unlike some electrode materials that may degrade or lose effectiveness over time, titanium electrodes maintain consistent performance throughout their operational life. This stability is crucial for ensuring that ballast water treatment systems continue to meet regulatory standards without frequent adjustments or replacements.

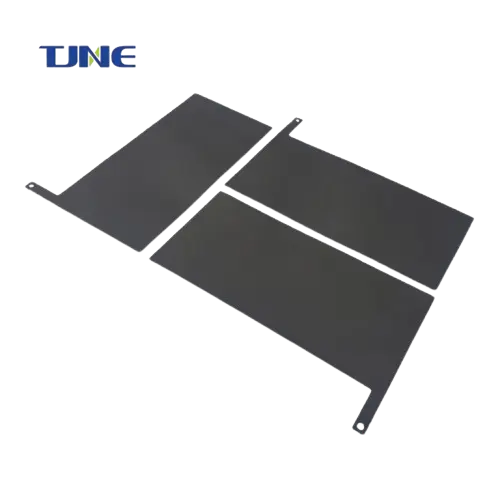

3. Versatility in Design: Titanium's strength and workability allow for the creation of electrodes in various shapes and configurations. This flexibility enables engineers to design more efficient and compact ballast water treatment systems, which is particularly important given the limited space available on ships.

4. Enhanced Safety: The use of titanium electrodes reduces the risk of electrode degradation and the potential release of harmful substances into the treated water. This aspect is particularly important in ballast water management, where the goal is to protect marine ecosystems from invasive species without introducing new environmental hazards.

5. Compatibility with Advanced Coatings: Titanium serves as an excellent substrate for advanced electrode coatings, such as mixed metal oxides (MMO). These coatings can further enhance the electrodes' performance, increasing their efficiency in generating disinfecting agents and potentially reducing power consumption.

6. Resistance to Scaling: In the marine environment, scaling (the buildup of mineral deposits) can be a significant issue for electrodes. Titanium's natural properties and the application of specialized coatings make these electrodes highly resistant to scaling, maintaining their efficiency over time and reducing the need for cleaning and maintenance.

7. Broad pH Range Tolerance: Titanium electrodes can operate effectively across a wide range of pH levels, which is beneficial given the varying conditions of ballast water from different parts of the world. This tolerance ensures consistent treatment efficacy regardless of the water's chemical composition.

8. Minimal Byproduct Formation: Compared to some other electrode materials, titanium electrodes, especially when properly coated, produce fewer unwanted byproducts during the electrolysis process. This characteristic is crucial for minimizing the environmental impact of ballast water treatment and ensuring compliance with increasingly stringent regulations.

9. Energy Efficiency: While the initial conductivity of titanium is lower than some metals, the use of advanced coatings and optimized designs allows titanium electrodes to achieve high energy efficiency in ballast water treatment applications. This efficiency helps to reduce the overall power consumption of the treatment system, an important factor in shipboard operations where energy management is critical.

10. Recyclability: At the end of their operational life, titanium electrodes are fully recyclable. This aligns with the growing emphasis on sustainability in the maritime industry and can contribute to a ship's overall environmental profile.

These advantages collectively make titanium electrodes the preferred choice for many ballast water treatment system manufacturers and ship operators. While alternative materials may offer certain benefits in specific scenarios, the overall performance, durability, and environmental compatibility of titanium electrodes make them particularly well-suited to the challenges of ballast water management.

How does the cost-effectiveness of titanium electrodes compare to alternatives in long-term ballast water management?

When evaluating the cost-effectiveness of titanium electrodes in ballast water management systems, it's essential to consider both the initial investment and the long-term operational costs. While titanium electrodes may have a higher upfront cost compared to some alternatives, their superior durability and performance characteristics often result in significant long-term savings and advantages:

1. Reduced Replacement Frequency: Titanium electrodes typically have a much longer operational life than alternatives like graphite or stainless steel. This longevity means fewer replacements over the lifetime of the ballast water treatment system, reducing both material costs and the labor expenses associated with electrode replacement.

2. Lower Maintenance Costs: The corrosion resistance and durability of titanium electrodes translate to reduced maintenance requirements. This not only lowers direct maintenance costs but also minimizes system downtime, which can be extremely costly in the shipping industry where time is a critical factor.

3. Consistent Efficiency: Unlike some electrode materials that may degrade or lose effectiveness over time, titanium electrodes maintain their performance characteristics throughout their operational life. This consistency ensures that the ballast water treatment system operates at optimal efficiency, potentially reducing energy costs and ensuring continuous compliance with regulations.

4. Energy Savings: When properly designed and coated, titanium electrodes can achieve high energy efficiency in electrolytic processes. Over the long term, this can result in significant energy savings, an important factor given the rising costs of fuel and increasing focus on reducing carbon emissions in the maritime industry.

5. Compliance Assurance: The reliability and consistent performance of titanium electrodes help ensure ongoing compliance with ballast water management regulations. This reduces the risk of costly fines, delays, or denied port entry due to non-compliance, which can have substantial financial implications for shipping companies.

6. Minimal Downtime: The durability of titanium electrodes means less frequent system failures or unplanned maintenance, reducing costly downtime for ships. In the competitive shipping industry, minimizing operational interruptions can provide a significant economic advantage.

7. Adaptability to Regulatory Changes: As ballast water treatment regulations continue to evolve, systems using titanium electrodes are well-positioned to meet more stringent requirements without major overhauls. This adaptability can save costs associated with system upgrades or replacements to meet new standards.

8. Reduced Environmental Liabilities: The use of titanium electrodes minimizes the risk of introducing harmful substances into the marine environment during the treatment process. This reduction in environmental liability can translate to cost savings by avoiding potential fines or legal issues related to environmental damage.

9. Space Efficiency: The high performance of titanium electrodes often allows for more compact system designs. On ships where space is at a premium, this can translate to more efficient use of available space, potentially freeing up room for cargo or other revenue-generating activities.

10. Lifecycle Cost Advantage: When considering the total lifecycle cost of a ballast water treatment system, including initial investment, operational costs, maintenance, and eventual replacement, titanium electrodes often emerge as the most cost-effective option. While the initial investment may be higher, the long-term savings and operational benefits typically outweigh this initial cost difference.

11. Value Retention: Ships equipped with high-quality ballast water treatment systems using titanium electrodes may retain their value better in the secondary market. This can be an important consideration for ship owners looking at the long-term financial implications of their equipment choices.

12. Scalability: As shipping companies look to standardize their ballast water treatment approaches across diverse fleets, the versatility and reliability of titanium electrode-based systems offer a scalable solution. This standardization can lead to economies of scale in procurement, maintenance, and crew training.

In conclusion, while the initial cost of titanium electrodes may be higher than some alternatives, their long-term cost-effectiveness is compelling. The combination of durability, performance consistency, reduced maintenance needs, and operational efficiency makes titanium electrodes a sound investment for ship owners and operators looking to optimize their ballast water management strategies over the long term. As the maritime industry continues to prioritize both environmental compliance and operational efficiency, the value proposition of titanium electrodes in ballast water treatment systems becomes increasingly clear.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References

1. International Maritime Organization. (2024). Ballast Water Management. 、

2. Werschkun, B., et al. (2022). Emerging risks from ballast water treatment: The run-up to the International Ballast Water Management Convention. Chemosphere, 112-891.

3. Čampara, L., Frančić, V., Maglić, L., & Hasanspahić, N. (2023). Overview and comparison of ballast water treatment technologies. Journal of Marine Science and Engineering, 11(3), 729.

4. Kim, E., Arias-Thode, Y. M., & Lee, K. (2021). Recent progress in electrochemical disinfection technologies for ballast water treatment. Journal of Environmental Chemical Engineering, 9(5), 106043.

5. Batista, W. R., et al. (2023). Electrochemical disinfection of ballast water: Challenges and opportunities. Water Research, 201, 117289.

6. Lloyd's Register. (2024). Understanding ballast water management. 、

7. Mouchtouri, V. A., et al. (2022). A review of the IMO International Convention for the Control and Management of Ships' Ballast Water and Sediments. Journal of Marine Science and Engineering, 10(2), 286.

8. Delacroix, S., et al. (2023). Efficacy and environmental impact of an innovative electrochemical ballast water treatment system. Environmental Science & Technology, 47(4), 2341-2348.

9. American Bureau of Shipping. (2024). Ballast Water Management Advisory. 、

10. Zhang, N., et al. (2023). Electrochemical technologies for ballast water treatment: Current status, challenges and future directions. Chemical Engineering Journal, 430, 132893.

Related Industry Knowledge

- What is a Titanium Electrode Used For in Saltwater Electrolysis?

- Advantages of Using Titanium Electrodes for Saltwater Electrolysis

- What is the Lifespan of Titanium Electrodes in Seawater Electrolysis Applications?

- Are Titanium Electrodes Resistant to Corrosion in Saltwater Electrolysis?

- How do Titanium Electrodes Enhance the Efficiency of Seawater Electrolysis?

- Can Titanium Anodes Be Used with Saltwater Pools?

- How to Choose the Right Titanium Electrode for Your Seawater Electrolysis Project?