- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Lifespan of Titanium Electrodes in Seawater Electrolysis Applications?

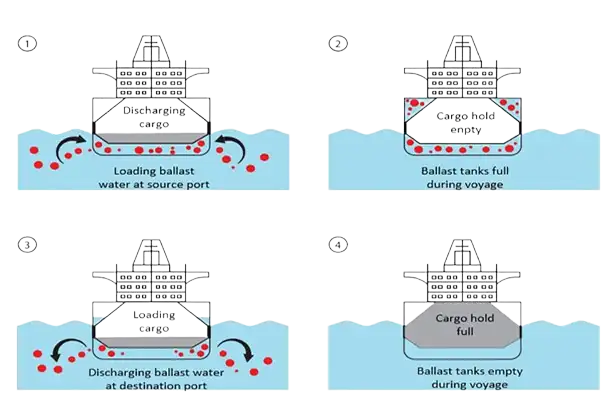

Titanium electrodes have become increasingly popular in seawater electrolysis applications due to their exceptional corrosion resistance and durability. These electrodes play a crucial role in various industrial processes, including desalination, and chlorine production. Understanding the lifespan of titanium electrodes in such demanding environments is essential for optimizing their use and ensuring cost-effective operations. In this blog post, we'll explore the factors that influence the longevity of titanium electrodes in seawater electrolysis and discuss their performance, durability, and potential for recycling.

How do titanium electrodes perform in seawater electrolysis?

Titanium electrodes have proven to be highly effective in seawater electrolysis applications, thanks to their unique properties and superior performance compared to other electrode materials. Their exceptional corrosion resistance, high strength-to-weight ratio, and ability to form a protective oxide layer make them ideal for use in harsh marine environments.

In seawater electrolysis, titanium electrodes are typically used as anodes, where they facilitate the oxidation of chloride ions to produce chlorine gas. The performance of these electrodes is characterized by several key factors:

1. Stability: Titanium electrodes demonstrate remarkable stability in seawater, maintaining their structural integrity and electrochemical properties over extended periods. This stability is primarily attributed to the formation of a passive titanium dioxide (TiO2) layer on the electrode surface, which acts as a barrier against corrosion and degradation.

2. Conductivity: While pure titanium is not an excellent electrical conductor, titanium electrodes used in seawater electrolysis are often coated with conductive materials such as mixed metal oxides (MMO) or platinum group metals (PGM). These coatings enhance the electrode's conductivity and catalytic activity, improving overall performance.

3. Efficiency: Titanium electrodes exhibit high faradaic efficiency in seawater electrolysis, meaning that a large proportion of the electrical energy supplied is converted into the desired chemical reactions. This efficiency translates to lower energy consumption and operational costs.

4. Selectivity: In chlorine production applications, titanium electrodes demonstrate excellent selectivity for chlorine evolution, minimizing the formation of unwanted by-products such as oxygen gas. This selectivity is crucial for maintaining high product quality and process efficiency.

5. Low overpotential: Titanium electrodes, especially when coated with suitable catalytic materials, exhibit low overpotential for chlorine evolution. This characteristic reduces the energy required to drive the electrolysis reaction, further enhancing the overall efficiency of the process.

The exceptional performance of titanium electrodes in seawater electrolysis has led to their widespread adoption in various industries. For instance, in desalination plants, titanium electrodes are used in electrochlorination systems to produce chlorine for disinfection purposes. In the chlor-alkali industry, these electrodes play a vital role in the production of chlorine, sodium hydroxide, and hydrogen from seawater or brine.

What factors affect the durability of titanium electrodes in seawater?

The durability of titanium electrodes in seawater electrolysis applications is influenced by a complex interplay of factors related to the electrode material, operating conditions, and environmental variables. Understanding these factors is crucial for predicting and extending the lifespan of titanium electrodes in industrial settings.

1. Coating composition and quality: Many titanium electrodes used in seawater electrolysis are coated with catalytic materials to enhance their performance. The composition and quality of these coatings significantly impact electrode durability. Mixed metal oxide (MMO) coatings, such as those containing iridium oxide (IrO2) and ruthenium oxide (RuO2), are commonly used due to their excellent catalytic properties and stability. However, the longevity of these coatings depends on factors such as coating thickness, uniformity, and adhesion to the titanium substrate.

2. Current density: The applied current density during electrolysis is a critical factor affecting electrode lifespan. Higher current densities generally lead to increased electrode wear and faster degradation of the catalytic coating. Operating at excessively high current densities can cause accelerated corrosion, delamination of the coating, and reduced overall electrode life. Conversely, maintaining current densities within the recommended range can significantly extend electrode durability.

3. Electrolyte composition: The chemical composition of seawater can vary depending on geographical location and environmental conditions. Factors such as salinity, pH, and the presence of impurities or organic matter can influence electrode durability. For instance, higher chloride concentrations may accelerate corrosion processes, while the presence of certain ions (e.g., calcium and magnesium) can lead to scale formation on the electrode surface, potentially reducing its effectiveness over time.

4. Temperature: Operating temperature plays a significant role in electrode durability. Higher temperatures generally accelerate chemical and electrochemical reactions, potentially leading to faster degradation of the electrode coating and substrate. Additionally, temperature fluctuations can cause thermal stress, potentially leading to cracking or delamination of the catalytic coating.

5. Gas evolution: The evolution of gases (primarily chlorine and oxygen) at the electrode surface during electrolysis can impact durability. Gas bubbles can cause localized high-current density spots, leading to uneven wear of the electrode coating. Moreover, the mechanical action of gas evolution can contribute to the erosion of the electrode surface over time.

By carefully considering and managing these factors, operators of seawater electrolysis systems can significantly extend the lifespan of titanium electrodes. This not only reduces operational costs associated with electrode replacement but also ensures consistent performance and reliability of the electrolysis process over extended periods.

Can titanium electrodes be recycled after use in seawater electrolysis?

The recyclability of titanium electrodes used in seawater electrolysis is an important consideration from both environmental and economic perspectives. As industries strive for more sustainable practices, the potential for recycling these electrodes has garnered increasing attention. The good news is that titanium electrodes can indeed be recycled after their use in seawater electrolysis applications, although the process involves several considerations and challenges.

1. Recyclability of titanium: Titanium is a highly recyclable metal, retaining its desirable properties even after multiple recycling cycles. This characteristic makes titanium electrodes excellent candidates for recycling once they reach the end of their operational life in seawater electrolysis systems. The recycling process for titanium generally consumes less energy compared to primary production, making it an environmentally favorable option.

2. Separation of components: Titanium electrodes used in seawater electrolysis typically consist of a titanium substrate coated with catalytic materials such as mixed metal oxides or platinum group metals. The first step in the recycling process involves separating these components. Advanced techniques like mechanical stripping, chemical leaching, or thermal treatment can be employed to remove the catalytic coating from the titanium substrate.

3. Recovery of precious metals: The catalytic coatings on titanium electrodes often contain valuable metals such as iridium, ruthenium, or platinum. These precious metals can be recovered through hydrometallurgical or pyrometallurgical processes. The recovery of these materials not only adds economic value to the recycling process but also reduces the demand for primary mining of these rare and expensive metals.

4. Reprocessing of titanium: Once the coating is removed, the titanium substrate can be reprocessed. This may involve melting and refining the titanium to remove any impurities accumulated during its use in seawater electrolysis. The recycled titanium can then be used to manufacture new electrodes or other titanium products, effectively closing the material loop.

5. Environmental benefits: Recycling titanium electrodes offers significant environmental advantages. It reduces the need for primary titanium production, which is an energy-intensive process. Additionally, recycling helps conserve natural resources and minimizes waste sent to landfills. The recovery of precious metals from the catalytic coatings also reduces the environmental impact associated with mining these materials.

6. Economic considerations: The economic viability of recycling titanium electrodes depends on various factors, including the market prices of titanium and precious metals, the efficiency of recycling technologies, and the scale of operations. As recycling technologies improve and environmental regulations become more stringent, the economic case for recycling these electrodes is likely to strengthen.

7. Challenges in recycling: Despite the potential benefits, recycling titanium electrodes from seawater electrolysis applications faces some challenges. These include:

- Contamination: Electrodes may contain various contaminants from seawater, which need to be removed during the recycling process.

- Complex coatings: Advanced electrode coatings may consist of multiple layers or complex compositions, making separation and recovery more challenging.

- Collection and transportation: Establishing efficient systems for collecting and transporting used electrodes from various locations to recycling facilities can be logistically challenging.

8. Emerging technologies: Research is ongoing to develop more efficient and cost-effective methods for recycling titanium electrodes. For example, some studies are exploring bio-hydrometallurgical processes using microorganisms to recover metals from spent electrodes. Other research focuses on improving the selectivity and efficiency of metal recovery processes.

In conclusion, the recyclability of titanium electrodes used in seawater electrolysis represents a promising avenue for enhancing the sustainability of these industrial processes. While challenges exist, ongoing research and technological advancements are continually improving the efficiency and economic viability of recycling these valuable components. As industries increasingly focus on circular economy principles, the recycling of titanium electrodes is likely to become an integral part of sustainable seawater electrolysis operations.

By considering the entire lifecycle of titanium electrodes, from production to use and finally to recycling, industries can significantly reduce their environmental footprint while potentially realizing economic benefits through the recovery of valuable materials. As technology advances and recycling processes become more sophisticated, the lifespan of titanium electrodes in seawater electrolysis applications extends beyond their operational use, contributing to a more sustainable and resource-efficient industrial landscape.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

2. Kraft, A. (2007). Doped diamond: a compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2(5), 355-385.

3. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

4. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

5. Sirés, I., Brillas, E., Oturan, M. A., Rodrigo, M. A., & Panizza, M. (2014). Electrochemical advanced oxidation processes: today and tomorrow. A review. Environmental Science and Pollution Research, 21(14), 8336-8367.

6. Chaplin, B. P. (2014). Critical review of electrochemical advanced oxidation processes for water treatment applications. Environmental Science: Processes & Impacts, 16(6), 1182-1203.

7. Moreira, F. C., Boaventura, R. A., Brillas, E., & Vilar, V. J. (2017). Electrochemical advanced oxidation processes: a review on their application to synthetic and real wastewaters. Applied Catalysis B: Environmental, 202, 217-261.

8. Radjenovic, J., & Sedlak, D. L. (2015). Challenges and opportunities for electrochemical processes as next-generation technologies for the treatment of contaminated water. Environmental Science & Technology, 49(19), 11292-11302.

9. Garcia-Segura, S., Ocon, J. D., & Chong, M. N. (2018). Electrochemical oxidation remediation of real wastewater effluents—A review. Process Safety and Environmental Protection, 113, 48-67.

10. Martínez-Huitle, C. A., Rodrigo, M. A., Sirés, I., & Scialdone, O. (2015). Single and coupled electrochemical processes and reactors

Related Industry Knowledge

- What are the Benefits of Using Titanium Electrodes in the Electrodeposition Process for Nickel And Cobalt?

- What are the Typical Applications for Nickel-Cobalt Alloys Electrodeposited on Titanium Electrodes?

- Why are titanium electrodes used specifically for ballast water management?

- Can Titanium Electrodes Help Reduce the Need for Pool Chemicals?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?

- Which electrolyzer is best for hydrogen production?