- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

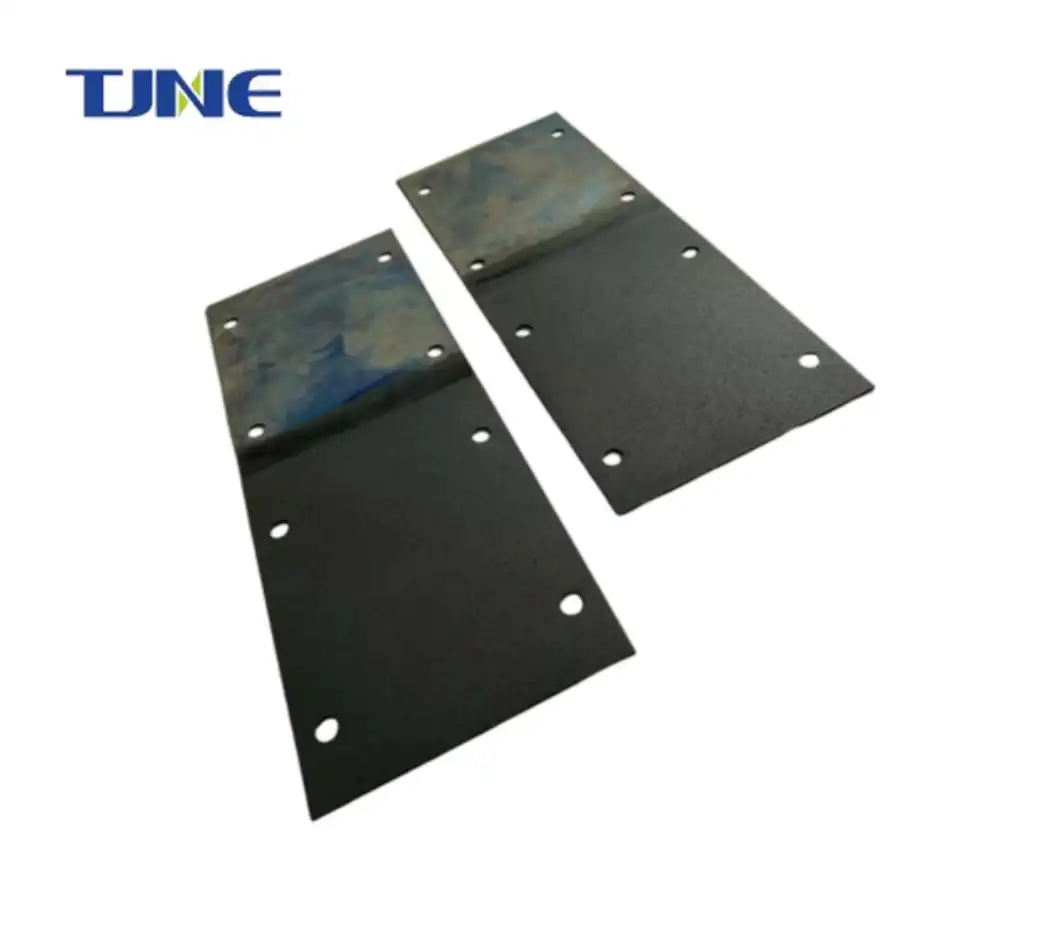

Titanium electrodes have emerged as a game-changing component in saltwater electrolysis, offering a powerful and efficient solution for various water treatment applications. These electrodes play a crucial role in the electrolytic process, which involves using electricity to break down saltwater into its constituent elements. The unique properties of titanium, including its exceptional corrosion resistance and electrical conductivity, make it an ideal material for electrodes in harsh saltwater environments. In this blog post, we'll explore the fascinating world of titanium electrodes in saltwater electrolysis and their wide-ranging applications.

Why are titanium electrodes preferred for saltwater electrolysis?

Titanium electrodes have become the go-to choice for saltwater electrolysis due to their outstanding properties and performance. The preference for titanium in this application stems from several key factors:

1. Corrosion Resistance: Saltwater is highly corrosive, capable of quickly degrading many metals. Titanium, however, forms a stable oxide layer on its surface when exposed to oxygen, providing exceptional resistance to corrosion. This protective layer allows titanium electrodes to withstand the harsh saltwater environment for extended periods, significantly increasing their lifespan compared to other materials.

2. Electrical Conductivity: While not as conductive as some metals like copper or silver, titanium offers a good balance of conductivity and corrosion resistance. When coated with noble metals like platinum or iridium, titanium electrodes can achieve even higher conductivity while maintaining their corrosion-resistant properties.

3. Durability: Titanium's high strength-to-weight ratio makes it an excellent choice for electrodes that need to withstand mechanical stress and frequent use. This durability ensures that titanium electrodes can operate reliably in demanding industrial applications.

4. Catalytic Properties: Titanium electrodes can be coated with catalytic materials to enhance their performance in specific electrolysis reactions. For example, ruthenium oxide-coated titanium electrodes are highly effective in chlorine production from saltwater.

5. Cost-Effectiveness: Although titanium is initially more expensive than some other electrode materials, its longevity and performance in saltwater environments make it a cost-effective choice in the long run. The reduced need for frequent replacements and maintenance contributes to lower overall operational costs.

6. Versatility: Titanium electrodes can be fabricated in various shapes and sizes, making them suitable for a wide range of electrolysis applications. From small-scale laboratory experiments to large industrial processes, titanium electrodes can be customized to meet specific requirements.

These advantages have made titanium electrodes the preferred choice for saltwater electrolysis in numerous industries, including water treatment, chlor-alkali production, and seawater desalination. As research continues to improve titanium electrode technology, we can expect to see even more efficient and cost-effective solutions for saltwater electrolysis in the future.

How does saltwater electrolysis with titanium electrodes work?

Saltwater electrolysis using titanium electrodes is a fascinating process that harnesses the power of electricity to break down salt (sodium chloride) and water into useful products. Understanding this process is crucial for appreciating the role of titanium electrodes in various applications. Let's break down the mechanism step by step:

1. Electrode Setup: The electrolysis system consists of two titanium electrodes - an anode (positively charged) and a cathode (negatively charged) - immersed in a saltwater solution, also known as brine.

2. Application of Electric Current: When an electric current is applied to the electrodes, it creates a potential difference between the anode and cathode. This electrical energy drives the electrolysis reaction.

3. Oxidation at the Anode: At the anode, chloride ions (Cl-) from the salt are oxidized, losing electrons to form chlorine gas (Cl2). The reaction can be represented as:

2Cl -- 2e → Cl2

4. Reduction at the Cathode: At the cathode, water molecules are reduced, gaining electrons to form hydrogen gas (H2). The reaction is:

2H++2e → H2

5. Formation of Sodium Hydroxide: The hydroxide ions produced at the cathode combine with sodium ions (Na+) from the salt to form sodium hydroxide (NaOH) in the solution.

6. Overall Reaction: The overall reaction in saltwater electrolysis can be summarized as:

NaCl+H2O → NaClO+H2 ↑

The role of titanium electrodes in this process is crucial:

- Stability: Titanium's corrosion resistance allows the electrodes to withstand the harsh chemical environment created during electrolysis. The protective oxide layer on the titanium surface prevents degradation, ensuring long-term performance.

- Efficiency: Titanium electrodes, especially when coated with catalytic materials, provide efficient electron transfer, minimizing energy losses during the electrolysis process.

- Selectivity: Depending on the coating applied to the titanium electrodes, they can be tailored to favor specific reactions. For example, certain coatings can enhance chlorine production while suppressing oxygen evolution.

- Durability: The mechanical strength of titanium allows the electrodes to maintain their shape and integrity over time, even under high current densities and gas evolution.

The products of saltwater electrolysis have numerous applications:

- Hydrogen gas can be used as a clean fuel or in industrial processes.

- Sodium hypochlorite is a valuable chemical used in many industries, water treatment, disinfection, and various industrial processes.

Advances in titanium electrode technology continue to improve the efficiency and selectivity of saltwater electrolysis. Researchers are exploring new coatings and surface modifications to enhance performance and reduce energy consumption. For example, nanostructured titanium electrodes have shown promise in increasing the surface area for reactions, potentially boosting efficiency.

Moreover, the scalability of saltwater electrolysis with titanium electrodes makes it suitable for applications ranging from small-scale water treatment systems to large industrial plants. This versatility has led to the adoption of titanium electrode-based electrolysis in various sectors, contributing to more sustainable and efficient processes in water treatment, chemical production, and energy generation.

What are the environmental benefits of using titanium electrodes in saltwater electrolysis?

The use of titanium electrodes in saltwater electrolysis offers significant environmental benefits, making it an increasingly popular choice for sustainable water treatment and chemical production processes. As global concerns about environmental impact and resource conservation continue to grow, the advantages of titanium electrodes in this application become even more apparent. Let's explore the key environmental benefits:

1. Energy Efficiency: Titanium electrodes, especially when coated with advanced catalytic materials, can significantly improve the energy efficiency of the electrolysis process. This increased efficiency means less electricity is required to produce the same amount of desired products, such as sodium hypochlorite or hydrogen. Reduced energy consumption directly translates to lower greenhouse gas emissions associated with power generation, contributing to climate change mitigation efforts.

2. Reduced Chemical Usage: Saltwater electrolysis using titanium electrodes often requires fewer additional chemicals compared to traditional water treatment methods. For instance, in water disinfection applications, the in-situ generation of sodium hypochlorite eliminates the need for transporting and storing large quantities of it, reducing the risk of chemical spills and associated environmental hazards.

3. Waste Reduction: The durability and longevity of titanium electrodes mean they need to be replaced less frequently than electrodes made from other materials. This longevity leads to reduced waste generation over time, minimizing the environmental impact associated with electrode production and disposal.

4. Sustainable Chemical Production: Using titanium electrodes in chlor-alkali process can make it more environmentally friendly by reducing energy consumption and improving product purity, leading to more sustainable chemical production practices.

5. Potential for Renewable Energy Integration: Titanium electrodes' efficiency makes this integration more feasible, potentially allowing for the production of valuable chemicals and treated water using clean energy.

6. Minimized Environmental Contamination: Unlike some other electrode materials, titanium does not leach harmful substances into the water during the electrolysis process. This property ensures that the treated water or produced chemicals are free from electrode-related contaminants, protecting both human health and aquatic ecosystems.

7. Recycling Potential: At the end of their operational life, titanium electrodes can be recycled. The recycling process for titanium is well-established, allowing for the recovery and reuse of this valuable metal, further reducing the environmental footprint of the electrolysis system.

8. Compact System Design: The high efficiency and durability of titanium electrodes often allow for more compact electrolysis system designs. Smaller systems require less construction material and occupy less space, reducing the overall environmental impact of installation and operation.

9. Versatility in Treating Different Water Sources: Titanium electrodes can effectively treat various water sources, including seawater, brackish water, and industrial wastewater. This versatility allows for the implementation of localized water treatment solutions, reducing the need for long-distance water transportation and its associated environmental costs.

The environmental benefits of using titanium electrodes in saltwater electrolysis extend beyond the immediate process. By enabling more efficient and sustainable water treatment and chemical production methods, these electrodes contribute to broader environmental goals such as water conservation, energy efficiency, and pollution reduction.

As research in this field continues, we can expect further improvements in titanium electrode technology. Current areas of investigation include developing new coating materials to enhance catalytic activity, optimizing electrode designs for even greater efficiency, and exploring ways to further integrate electrolysis systems with renewable energy sources.

The adoption of titanium electrodes in saltwater electrolysis represents a significant step towards more sustainable industrial processes. As industries and governments increasingly prioritize environmental protection and resource conservation, the role of titanium electrodes in achieving these goals is likely to expand, driving innovation and contributing to a more sustainable future.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References

1. Kraft, A. (2008). Electrochemical Water Disinfection: A Short Review. Platinum Metals Review, 52(3), 177-185.

2. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

3. Mazloomi, K., & Gomes, C. (2012). Hydrogen as an energy carrier: Prospects and challenges. Renewable and Sustainable Energy Reviews, 16(5), 3024-3033.

4. Moreno-Casillas, H. A., Cocke, D. L., Gomes, J. A., Morkovsky, P., Parga, J. R., & Peterson, E. (2007). Electrocoagulation mechanism for COD removal. Separation and Purification Technology, 56(2), 204-211.

5. Nagai, N., Takeuchi, M., Kimura, T., & Oka, T. (2003). Existence of optimum space between electrodes on hydrogen production by water electrolysis. International Journal of Hydrogen Energy, 28(1), 35-41.

6. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

7. Rajeshwar, K., & Ibanez, J. G. (1997). Environmental electrochemistry: Fundamentals and applications in pollution sensors and abatement. Academic Press.

8. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

9. Vaccaro, A. R., Javadi, S., & Johnson, S. (2019). Saltwater Chlorination Systems: A Review of the Technology and Its Applications. Journal of Water Process Engineering, 32, 100909.

10. Zoski, C. G. (Ed.). (2007). Handbook of electrochemistry. Elsevier.