- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

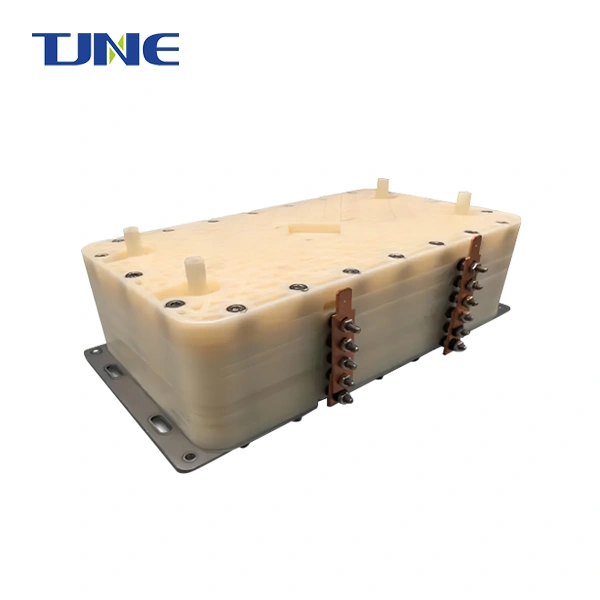

Iridium Tantalum Coated Titanium Anode

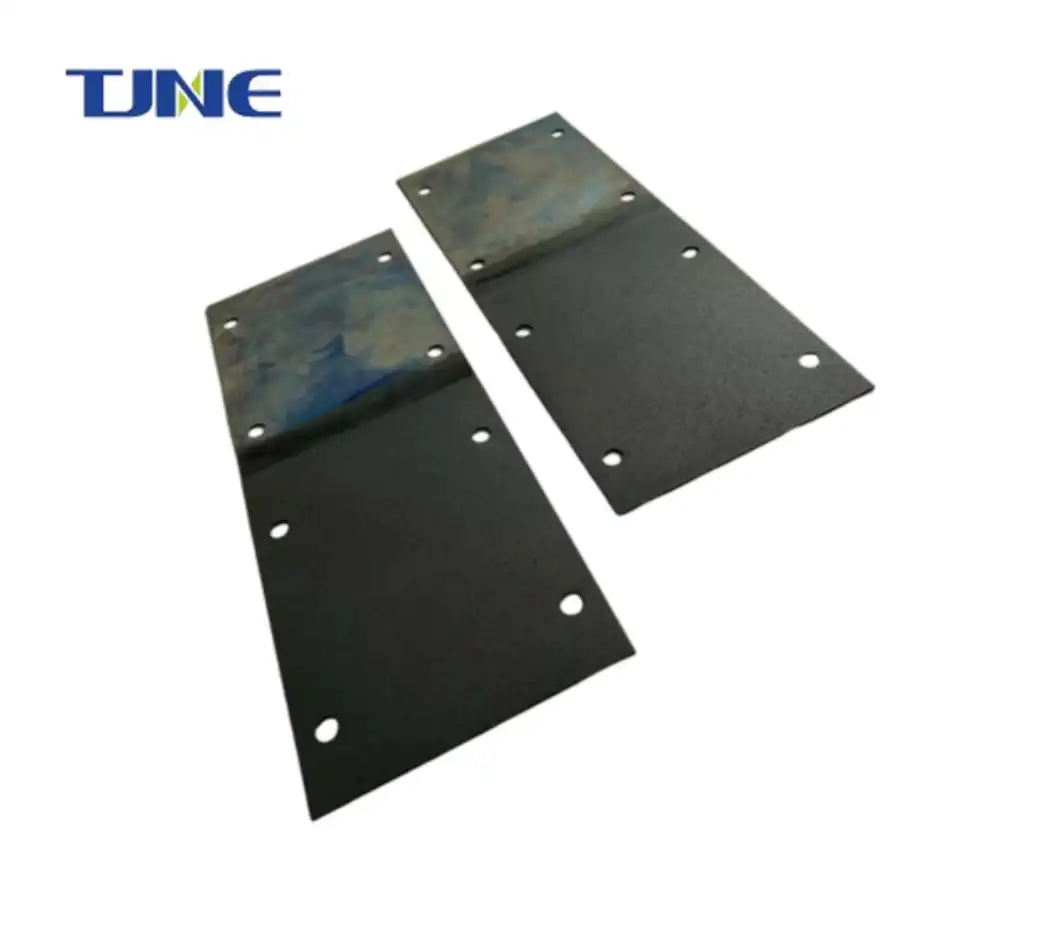

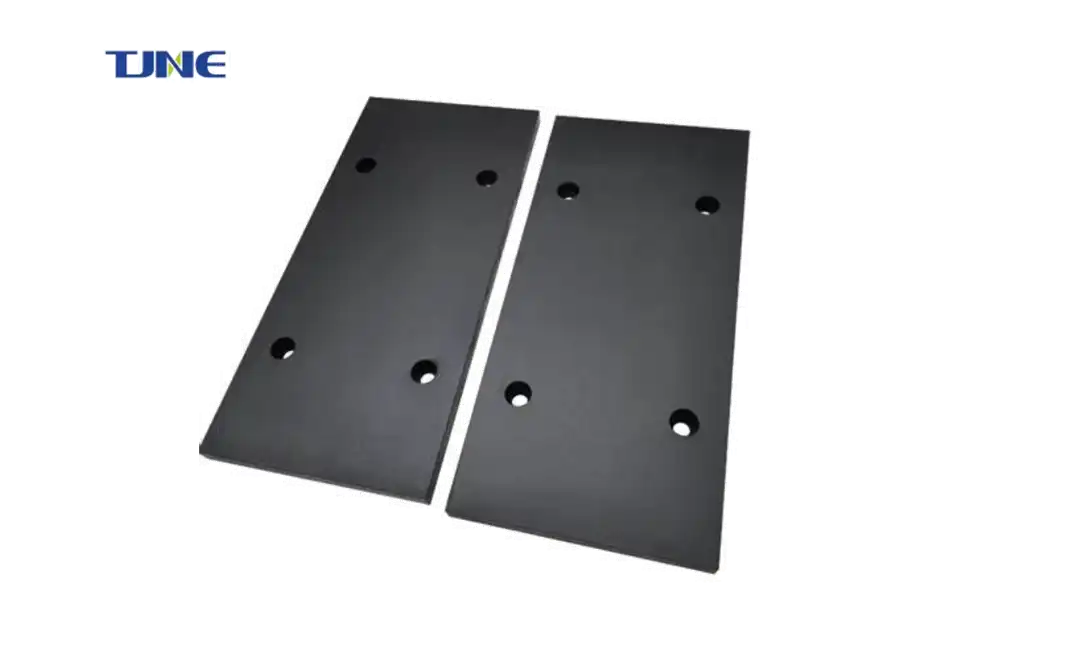

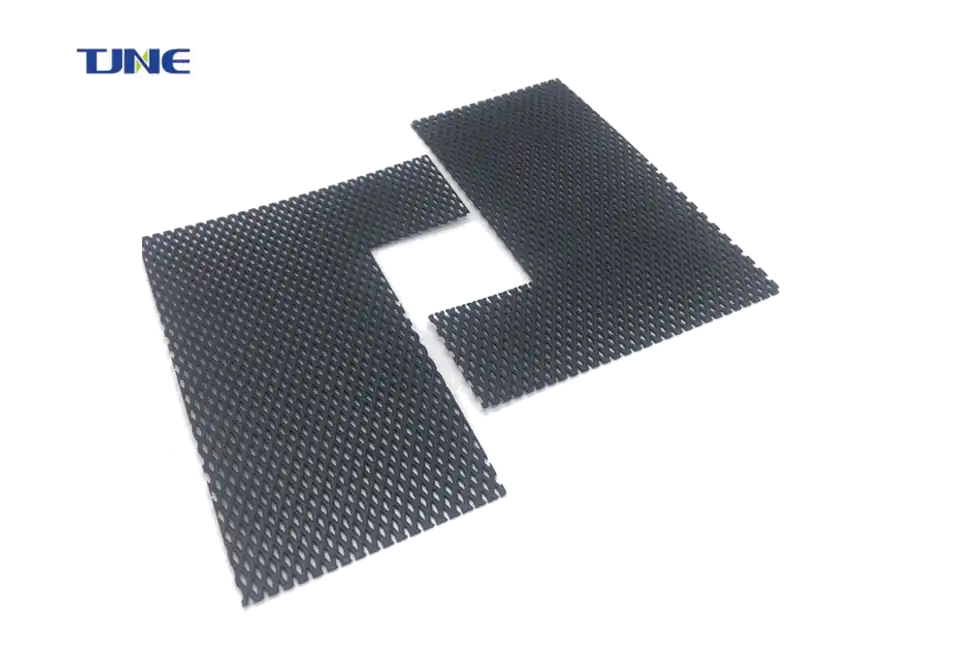

2.Material size: Customized into various shapes, including plate, mesh, wire, and tube. Different shapes have several thickness such as 1mm, 1.5mm, 2mm, 2.5mm and more.

3.Coating: Coated with iridium and tantalum metal coatings, with a service life more than 5 years. The oxygen potential is greater than or equal to 1.9v and the current density is 2000A/m2.

4.Coating thickness: 0.2-20μm, maintaining stable operation in harsh electrochemical environments.

5.Application: Used for water treatment, electrocatalytic oxidation, chlor-alkali industry, electroplating, electrochemical synthesis and cathodic protection.

The iridium tantalum coated titanium anode produced by TJNE represents a cutting-edge advancement in high-performance electrochemical anode materials, tailored for various demanding applications. This innovative anode is primarily utilized in electrolysis, electroplating, electrocatalysis, and other electrochemical processes, where reliability and efficiency are paramount. These coatings not only enhance the anode's performance but also significantly extend its lifespan, ensuring that it can operate effectively even in harsh electrochemical environments. Such environments often present challenges, including high temperatures and aggressive chemical conditions, which can lead to rapid degradation of standard materials. However, the iridium and tantalum coatings are specifically designed to maintain stable operation under these strenuous conditions, offering superior resistance to corrosion and electrochemical wear.

Iridium tantalum coated titanium anode is highly sought after in industries that require precise and efficient electrochemical reactions, such as in water treatment, energy storage, and the production of chemicals.

Our anodes are available in several sizes and shapes to meet different process conditions. The main features and advantages of the anodes are as follows:

Excellent corrosion resistance with coating thickness ranging from 0.2-20μm, maintaining good performance in harsh electrochemical environment

High catalytic oxidation ability with oxygen potential greater than or equal to 1.9v

Good electrical conductivity and low resistivity, beneficial to

improving the efficiency of the electrolysis process

Environmental friendly, releasing almost no harmful substances during the electrochemical process

| Item | Parameter |

|---|---|

| Substrate | GR1, GR2 |

| Substrate shape | Plate, mesh, tube, wire |

| Coating thickness | 0.2-20μm |

| Oxygen potential | ≥1.9V |

| Current efficiency | ≥95% |

| Operating temperature | 4-50 °C |

| Max current density | 2000A/m2 |

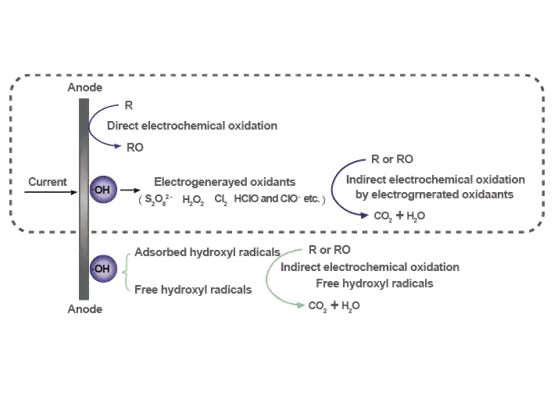

Working Principle

The iridium tantalum coating provides excellent corrosion resistance, even in harsh chemical environments. It exhibits superior stability and durability during electrolysis, making it ideal for applications such as water treatment, electroplating, and electrochemical synthesis. The coating protects the titanium substrate from degradation and enhances the anode's overall lifespan.

Application

Water treatment

Iridium tantalum coated titanium anodes find application in water treatment, where the anodes works for processes like electro-oxidation and electrochemical disinfection of municipal wastewater and industrial effluents. The anodes also exhibit outstanding electrocatalytic activity for oxygen evolution from water, generating reactive oxidants to degrade organic pollutants and inactivate disease-causing pathogens.

Electrocatalytic Oxidation

Used for wastewater treatment, utilizing specific chemical reactions to effectively remove pollutants, disinfect water, and oxidize organic compounds (COD), ammonia nitrogen, decolorization, etc. These anodes play a crucial role in improving water quality and achieving environmental sustainability.

Chlor-alkali industry

The chlor-alkali industry utilizes iridium tantalum coated titanium extensively in the electrolysis of brine for chlorine and caustic soda production. The electrodes withstand the highly corrosive brine environment while also electrolyzing salt efficiently over prolonged production runs. The dimensional stability of the titanium substrate coupled with the electrocatalytic activity of the iridium tantalum coating enables consistent and reliable performance.

Electroplating

For metal electroplating processes, like chromium plating, and other electroplating applications including nickel, copper, tin, zinc, and precious metals, iridium tantalum coated titanium anodes provide inert, non-consumable anodes necessary for uniform metal deposition onto cathodic workpieces. The anodes eliminate metal contamination from anode dissolution observed with consumable metal anodes.

Electrochemical synthesis

In the electrochemical synthesis of organic compounds and specialty chemicals, iridium tantalum coated titanium anodes withstands aggressive organic intermediates/reagents while facilitating selective electrochemical oxidation reactions at its surface. In case applications, like electrochemical fluorination and electrophilic aromatic substitution, iridium tantalum coated titanium electrodes can produce useful fluorinated and chlorinated aromatic compounds.

Cathodic protection

Additionally, iridium tantalum coated titanium anode is used as an inert auxiliary anode material in cathodic protection systems for corrosion prevention in pipelines, storage tanks, marine structures, and other metal infrastructure.

FAQ

How long does the Iridium tantalum coating last?

Our anodes have a service life of at least 5 years under normal operating conditions.

Can the anodes be customized to specific sizes?

Yes, we offer customization services to meet your unique requirements.

What is the recommended current density for these anodes?

The recommended maximum current density is 2000 A/m2.

Are the anodes suitable for highly corrosive environments?

Yes, the iridium tantalum coating provides excellent corrosion resistance, making the anodes suitable for use in aggressive environments.

Contact Us

Choose TJNE as your reliable supplier of iridium tantalum coated titanium anode. Our strong technical expertise, comprehensive one-stop service, and high-quality products ensure your satisfaction. Contact us at yangbo@tjanode.com to discuss your specific requirements.