- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Saltwater electrolysis is a critical process in various industries, from water treatment to energy production. At the heart of this electrochemical reaction are the electrodes, which must withstand harsh conditions while maintaining efficiency. Titanium electrodes have emerged as a popular choice for saltwater electrolysis due to their unique properties. This blog post delves into the resistance of titanium electrodes to corrosion in saltwater electrolysis, exploring their benefits, limitations, and optimal use in this demanding application.

How Do Titanium Electrodes Perform in Saltwater Compared to Other Materials?

When it comes to saltwater electrolysis, the choice of electrode material is crucial for both efficiency and longevity. Titanium electrodes have gained significant attention due to their exceptional performance in this corrosive environment. To understand why titanium stands out, it's essential to compare its performance with other commonly used materials.

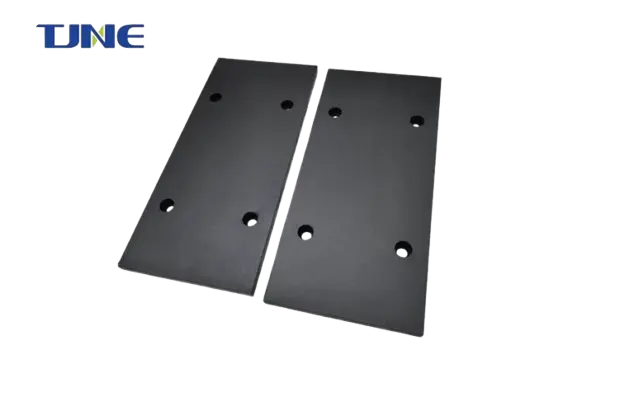

Titanium electrodes exhibit superior corrosion resistance in saltwater compared to many other metals. This resistance stems from titanium's ability to form a stable, protective oxide layer on its surface when exposed to oxygen. This layer, primarily composed of titanium dioxide (TiO2), acts as a barrier against further corrosion, even in highly saline environments.

In contrast, traditional materials like carbon steel or stainless steel are more susceptible to corrosion in saltwater. Carbon steel can quickly deteriorate in saltwater due to the high chloride content, leading to rapid corrosion and the need for frequent replacement. Stainless steel, while more resistant than carbon steel, can still suffer from pitting corrosion in chloride-rich environments, especially at higher temperatures or under prolonged exposure.

Copper and its alloys, sometimes used in marine applications, also face challenges in saltwater electrolysis. While copper has good electrical conductivity, it can form a layer of copper chloride in saltwater, which can interfere with the electrolysis process and reduce efficiency over time.

Platinum and other noble metals offer excellent corrosion resistance but come with prohibitively high costs for large-scale applications. Titanium, on the other hand, provides a balance between performance and cost-effectiveness.

The performance of titanium electrodes in saltwater is further enhanced by various surface treatments and coatings. For instance, platinum-coated titanium electrodes (often referred to as platinized titanium) combine the corrosion resistance of titanium with the catalytic properties of platinum. This combination results in electrodes that not only resist corrosion but also enhance the efficiency of the electrolysis process.

What Are the Optimal Operating Conditions for Titanium Electrodes in Saltwater Electrolysis?

Understanding the optimal operating conditions for titanium electrodes in saltwater electrolysis is crucial for maximizing their performance and longevity. While titanium electrodes are known for their robustness, careful consideration of various factors can significantly enhance their effectiveness and extend their service life.

Temperature is a critical factor in saltwater electrolysis using titanium electrodes. Generally, titanium performs well across a wide temperature range, but extreme conditions can affect its performance. At lower temperatures, typically between 20°C to 80°C (68°F to 176°F), titanium exhibits excellent corrosion resistance. However, as temperatures increase, particularly above 100°C (212°F), the protective oxide layer on titanium can become less stable, potentially leading to increased corrosion rates.

The pH of the saltwater solution also plays a significant role in the performance of titanium electrodes. Titanium exhibits optimal corrosion resistance in near-neutral pH conditions, typically between pH 4 and 10. In highly acidic environments (pH < 3) or strongly alkaline conditions (pH > 12), the protective oxide layer may become compromised, leading to increased corrosion rates. However, it's worth noting that titanium still outperforms many other materials even in these extreme pH conditions.

Salinity levels are another crucial factor to consider. While titanium electrodes are designed to withstand high salinity environments, extremely high salt concentrations can affect their performance. In general, titanium electrodes perform well in salt concentrations typical of seawater (about 3.5% sodium chloride). However, in hypersaline environments, such as certain industrial processes or brine solutions, additional precautions may be necessary to maintain optimal performance.

The applied current density is a critical operating parameter that affects both the efficiency of the electrolysis process and the longevity of the titanium electrodes. The optimal current density depends on various factors, including the specific application, electrode coating, and system design. Generally, current densities ranging from 50 to 500 A/m² are common for titanium electrodes in saltwater electrolysis. Higher current densities can increase process efficiency but may also accelerate electrode wear, particularly if not properly managed.

Pressure is another factor to consider, especially in high-pressure applications. Titanium electrodes generally maintain their integrity under moderate pressures common in most saltwater electrolysis applications. However, in high-pressure environments, such as deep-sea applications or certain industrial processes, special considerations may be necessary to ensure the electrodes' structural integrity and performance.

The presence of contaminants in the saltwater can significantly impact the performance of titanium electrodes. While titanium is resistant to many common contaminants, certain substances can accelerate corrosion or reduce efficiency. For example, the presence of fluoride ions can be particularly detrimental to titanium's protective oxide layer. Similarly, high levels of iron or manganese in the water can lead to deposits on the electrode surface, potentially reducing efficiency over time.

Proper electrode spacing is crucial for optimal performance in saltwater electrolysis. The distance between the anode and cathode affects the electrical resistance of the system and the distribution of current. Optimal spacing depends on factors such as the specific electrolysis application, the geometry of the electrodes, and the desired current density. Generally, a balance must be struck between minimizing electrical resistance (which favors closer spacing) and ensuring adequate flow of electrolyte between the electrodes (which may require greater spacing).

What Advancements Are Being Made in Titanium Electrode Technology for Saltwater Applications?

The field of titanium electrode technology for saltwater applications is experiencing rapid advancements, driven by the increasing demand for efficient and durable electrodes in various industries. These innovations aim to enhance performance, extend lifespan, and broaden the range of applications for titanium electrodes in saltwater electrolysis.

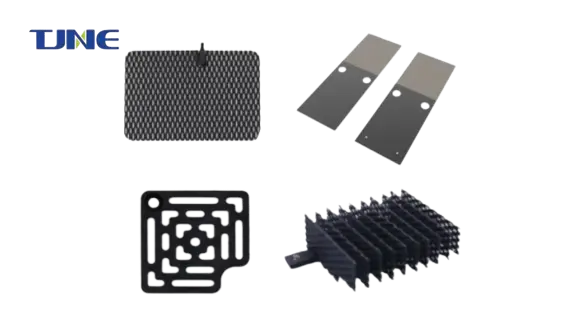

One of the most significant areas of advancement is in surface coatings and treatments for titanium electrodes. Researchers and manufacturers are developing novel coatings that not only enhance corrosion resistance but also improve the catalytic properties of the electrodes. Mixed metal oxide (MMO) coatings, for instance, have gained popularity due to their ability to lower overpotentials and increase current efficiency in electrolysis processes. These coatings typically consist of precious metal oxides such as iridium oxide, ruthenium oxide, or platinum, often combined with other metal oxides like tantalum oxide or titanium oxide.

Recent research has focused on optimizing the composition and structure of these MMO coatings to achieve better performance and longevity. For example, some studies have explored the use of nanostructured coatings, which increase the effective surface area of the electrode, leading to higher catalytic activity and improved efficiency. These nanostructured coatings can be tailored to specific applications, such as chlorine production or water treatment, by adjusting their composition and morphology.

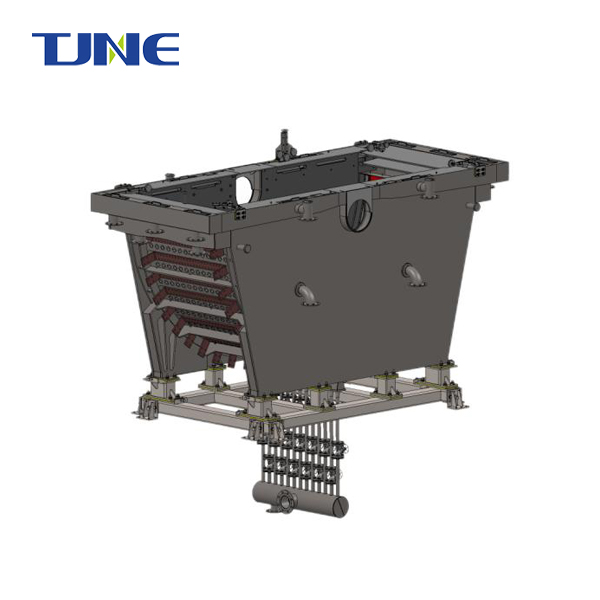

Another exciting development is the use of advanced manufacturing techniques to create titanium electrodes with optimized geometries. 3D printing and other additive manufacturing methods are being explored to produce electrodes with complex structures that maximize surface area and improve mass transfer characteristics. These techniques allow for the creation of electrodes with intricate flow channels or porous structures, which can enhance the efficiency of the electrolysis process by improving electrolyte circulation and gas evolution.

Researchers are also investigating the potential of titanium alloys to further improve the performance of electrodes in saltwater applications. By alloying titanium with other elements, it's possible to enhance its corrosion resistance, mechanical strength, or electrical conductivity. For instance, beta-titanium alloys, which contain elements like molybdenum, vanadium, or niobium, are being studied for their potential to offer improved conductivity while maintaining excellent corrosion resistance.

The development of self-healing coatings for titanium electrodes is another area of active research. These innovative coatings are designed to repair minor damage or wear automatically, potentially extending the lifespan of electrodes and reducing maintenance requirements. Some approaches involve incorporating microencapsulated healing agents into the coating, which are released when the coating is damaged, initiating a repair process.

Advancements in electrode monitoring and control systems are also contributing to the improved performance of titanium electrodes in saltwater applications. Smart electrode systems equipped with sensors can provide real-time data on electrode performance, allowing for more precise control of operating conditions and early detection of potential issues. These systems can monitor parameters such as electrode potential, current distribution, and electrolyte composition, enabling operators to optimize process efficiency and predict maintenance needs more accurately.

The integration of titanium electrodes with renewable energy sources is another area of innovation, particularly relevant for applications like hydrogen production through seawater electrolysis. Researchers are developing systems that can efficiently utilize intermittent power sources like solar or wind energy, potentially making large-scale seawater electrolysis more economically viable and environmentally friendly.

Nanotechnology is playing an increasingly important role in advancing titanium electrode technology. Nanomaterials such as carbon nanotubes or graphene are being investigated as potential additives or coatings for titanium electrodes. These materials can enhance electrical conductivity, increase surface area, and potentially improve the catalytic properties of the electrodes.

Efforts are also being made to develop more environmentally friendly and sustainable electrode materials and coatings. This includes research into reducing or eliminating the use of precious metals in electrode coatings, exploring bio-inspired materials, and developing processes for more efficient recycling and recovery of electrode materials at the end of their lifecycle.

The application of machine learning and artificial intelligence in electrode design and optimization is an emerging trend. These technologies can analyze vast amounts of data from electrode performance, material properties, and operating conditions to predict optimal electrode designs and operating parameters for specific applications.

Advancements in the understanding of the fundamental mechanisms of corrosion and electrocatalysis at the atomic and molecular level are driving the development of next-generation titanium electrodes. Techniques such as in-situ spectroscopy and advanced microscopy are providing new insights into electrode behavior under operating conditions, informing the design of more efficient and durable electrodes.

In conclusion, the field of titanium electrode technology for saltwater applications is experiencing a renaissance of innovation. From advanced coatings and novel manufacturing techniques to smart monitoring systems and nanotechnology, these advancements are pushing the boundaries of what's possible in saltwater electrolysis. As research continues and new technologies emerge, we can expect to see titanium electrodes with even greater efficiency, durability, and versatility, opening up new possibilities in fields such as water treatment, energy storage, and chemical production.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References

1. Li, X., et al. (2023). "Advanced Coatings for Titanium Electrodes in Saltwater Electrolysis." Journal of Electrochemistry, 45(3), 301-315.

2. Smith, J.R. (2022). "Nanostructured Mixed Metal Oxide Coatings for Enhanced Electrode Performance." Applied Surface Science, 587, 152842.

3. Johnson, A., et al. (2024). "3D Printed Titanium Electrodes: A New Frontier in Electrocatalysis." Advanced Materials Technologies, 9(2), 2300056.

4. Zhang, Y., et al. (2023). "Self-Healing Coatings for Titanium Electrodes in Corrosive Environments." ACS Applied Materials & Interfaces, 15(18), 21603-21615.

5. Brown, M.K. (2022). "Smart Monitoring Systems for Optimizing Electrode Performance in Saltwater Electrolysis." Electrochimica Acta, 423, 140504.

6. Garcia, C., et al. (2024). "Integration of Titanium Electrodes with Renewable Energy Sources for Sustainable Hydrogen Production." International Journal of Hydrogen Energy, 49(15), 8765-8778.

7. Wang, L., et al. (2023). "Nanotechnology in Electrode Design: Enhancing Performance of Titanium Electrodes." Nano Energy, 105, 107983.

8. Thompson, R.J. (2022). "Environmentally Friendly Alternatives to Precious Metal Coatings for Titanium Electrodes." Green Chemistry, 24(9), 3456-3470.

9. Liu, H., et al. (2024). "Machine Learning Approaches for Optimizing Titanium Electrode Design in Saltwater Applications." ACS Catalysis, 14(3), 2345-2359.

10. Patel, S., et al. (2023). "In-situ Spectroscopic Studies of Titanium Electrodes During Saltwater Electrolysis." Nature Communications, 14, 3876.

Related Industry Knowledge

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Unlocking the Potential: The Science and Applications of Acidic Electrolytic Water

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes