- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

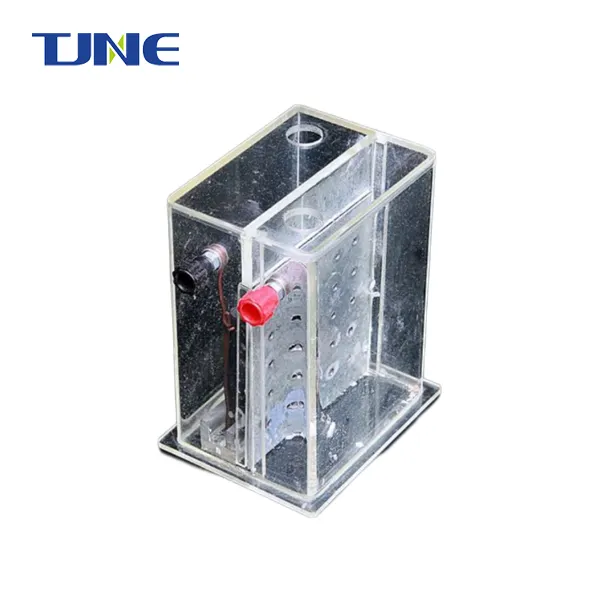

In the realm of electrochemistry, Anode Plates play a pivotal role, acting as the positive electrode in various electrolytic processes. Understanding the fundamental role and function of Anode Plates is essential for anyone involved in electrochemical applications.

Anode Plates are basic components in electrolytic cells, where they encourage the oxidation response by giving a location for electron discharge. This handle is pivotal for various mechanical forms, counting metal electroplating, water treatment, and electrolysis of different chemicals.

The essential work of Anode Plates is to serve as conductive substrates for the electrochemical response to happen. Regularly made from materials such as graphite, titanium, or blended metal oxides, Anode Plates must show fabulous electrical conductivity, erosion resistance, and mechanical quality to withstand unforgiving working conditions.

The plan of Anode Plates is custom fitted to particular applications, with varieties in estimate, shape, and fabric composition depending on the electrolyte, current thickness, and wanted response energy. Engineers carefully select the suitable Anode Plate setup to optimize execution and effectiveness in assorted electrochemical processes.

Understanding the electrochemical energy at the Anode Plate surface is vital for maximizing effectiveness and efficiency. Components such as surface range, surface unpleasantness, and catalyst coating altogether impact the response energy and generally execution of Anode Plates.

In expansion to their essential work as electron givers, Anode Plates too play a imperative part in controlling the conveyance of current inside the electrolyte. Appropriate current dissemination is fundamental for accomplishing uniform statement or disintegration of particles, guaranteeing high-quality item results in electrochemical forms.

Materials Matter: The Different Types of Anode Plates and Their Applications

The choice of material for Anode Plates is dictated by the specific requirements of the electrochemical process. Different materials offer unique properties that can be tailored to optimize performance and durability in various applications.

Graphite Anode Plates are commonly used in electrochemical processes where high conductivity and chemical resistance are paramount. Graphite's excellent electrical properties and corrosion resistance make it ideal for applications such as electroplating, electrolytic synthesis, and chlor-alkali production.

Titanium Anode Plates are favored for their exceptional corrosion resistance, particularly in aggressive environments such as seawater electrolysis and electrochemical wastewater treatment. The passive oxide layer that forms on titanium surfaces provides long-term protection against corrosion, ensuring the longevity of Anode Plates in harsh operating conditions.

Mixed metal oxide (MMO) Anode Plates combine the advantages of both graphite and titanium, offering superior conductivity and corrosion resistance. MMO coatings provide catalytic activity, enhancing reaction kinetics and overall efficiency in electrolytic processes such as water disinfection, electrowinning, and cathodic protection.

Innovations in Anode Plate materials continue to drive advancements in electrochemical technologies, with researchers exploring novel materials and coatings to improve performance, reduce costs, and enhance sustainability in various applications.

Innovation in Action: Latest Advances in Anode Plate Technology

The field of Anode Plate technology is witnessing rapid advancements driven by innovations in materials, manufacturing techniques, and design methodologies. These advancements aim to address current challenges and unlock new opportunities in electrochemical applications.

One area of innovation is the development of nanostructured Anode Plates, which offer increased surface area and enhanced catalytic activity. Nanostructured materials such as nanotubes, nanowires, and nanoparticles enable precise control over electrochemical reactions, leading to improved efficiency and selectivity in various processes.

Advances in coating technologies have also contributed to the improvement of Anode Plate performance and durability. Novel coatings, such as conductive polymers and thin film composites, provide enhanced corrosion resistance and catalytic activity, extending the lifespan of Anode Plates in aggressive environments.

Furthermore, additive manufacturing techniques, such as 3D printing, enable the rapid prototyping and customization of Anode Plates with complex geometries. This flexibility in design allows for optimized current distribution and improved process efficiency in niche applications.

The integration of digital monitoring and control systems represents another frontier in Anode Plate innovation. Real-time monitoring of operating parameters, such as temperature, pH, and current density, enables proactive maintenance and optimization of electrochemical processes, leading to increased reliability and productivity.

Sustainability and Efficiency: Anode Plates in Modern Environmental Solutions

In an era where environmental sustainability is of paramount importance, the role of Anode Plates in modern environmental solutions cannot be overstated. Electrochemical processes enabled by Anode Plates offer sustainable alternatives to traditional chemical and mechanical methods, with reduced energy consumption, waste generation, and environmental impact.

Electrochemical wastewater treatment, for example, utilizes Anode Plates to facilitate the oxidation of organic pollutants and the removal of heavy metals from industrial effluents. By harnessing the power of electrochemistry, this approach minimizes the use of chemicals and eliminates the production of harmful by-products, contributing to cleaner waterways and healthier ecosystems.

Similarly, electrochemical synthesis processes enabled by Anode Plates offer greener alternatives to traditional chemical manufacturing methods. By leveraging renewable energy sources and catalytic materials, electrochemical processes can produce valuable chemicals and fuels with higher efficiency and lower environmental footprint.

Furthermore, the recycling and recovery of valuable metals from electronic waste represent another area where Anode Plate technology can make a significant impact. Electrochemical methods allow for selective extraction and purification of metals, such as copper, nickel, and gold, from complex electronic devices, contributing to resource conservation and circular economy principles.

Conclusion

In conclusion, Anode Plates play a crucial role in advancing sustainability and efficiency in modern electrochemical applications. By embracing innovation and leveraging the unique properties of Anode Plate materials, we can continue to drive positive environmental change and build a more sustainable future.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of Anode Plate, welcome to contact us: yangbo@tjanode.com

References

1. Bard, A. J., & Faulkner, L. R. (2001). Electrochemical Methods: Fundamentals and Applications (2nd ed.). John Wiley & Sons.

2. Compton, R. G., & Banks, C. E. (Eds.). (2018). Understanding Voltammetry: Simulation of Electrode Processes (4th ed.). World Scientific Publishing.

3. Horkans, B. (2009). Electrochemical Dictionary (2nd ed.). Springer.

4. Koryta, J., Dvořák, M., & Peřina, V. (2011). Ion-Selective Electrodes (4th ed.). Springer.

5. Trasatti, S. (Ed.). (2001). Electrochemical Dictionary (2nd ed.). Springer.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- How Do Anodes Facilitate the Removal of Ammonia Nitrogen from Water?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- Unlocking the Potential: The Science and Applications of Acidic Electrolytic Water

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What is a DSA Anode and How Does It Work?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?