- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

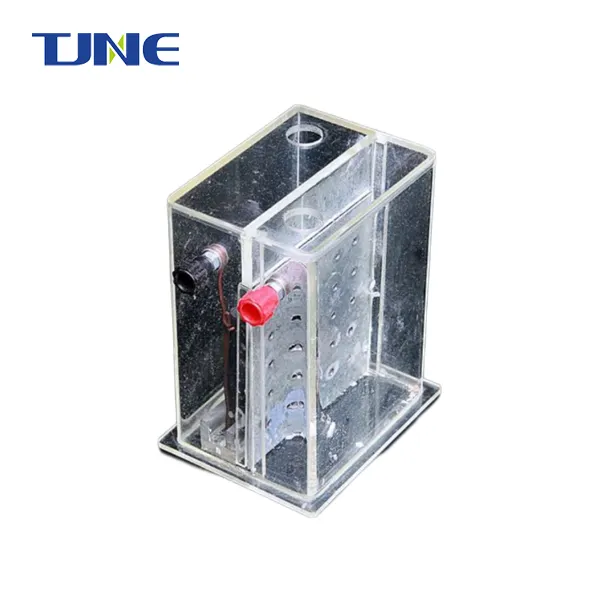

Membrane Electrolysis for NaCl

Product overview: It is a device that uses membrane electrolysis technology to prepare sodium chloride.

Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.

Application fields: water treatment, hydrogen and oxygen production, environmental protection, and chemical industry.

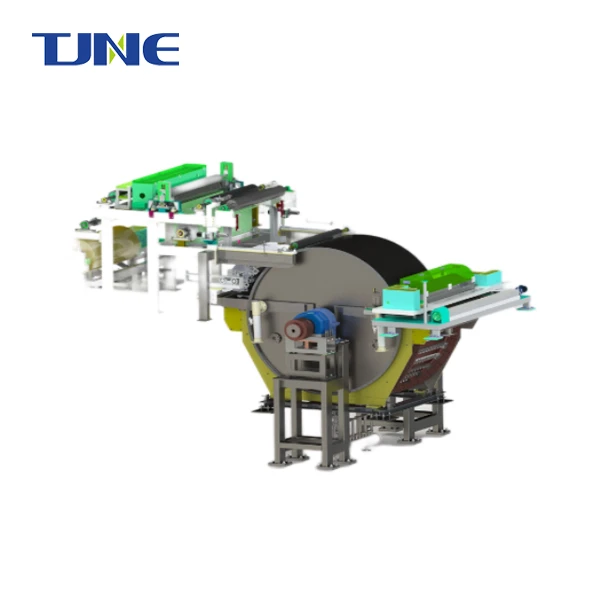

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

What is Membrane electrolysis for NaCl?

Membrane Electrolysis for NaCl is an advanced technology that utilizes a membrane to electrolyze sodium chloride( NaCl) result, performing in the product of chlorine gas( Cl2) and sodium hydroxide( NaOH).

This process is carried out in an electrolytic cell with applicable anodes and cathodes. When an electric current is passed through the NaCl result, sodium ions resettle towards the cathode, while chloride ions resettle towards the anode. At the cathode, water motes are reduced to produce hydrogen gas and hydroxide ions, while at the anode, chloride ions are oxidized to produce chlorine gas. The hydroxide ions combine with the sodium ions to form sodium hydroxide result.

System Composition:

The membrane electrolysis system consists of the following components:

An electrolytic cell with ion-exchange membranes

Anode and cathode electrodes

Power supply

Controls and monitoring system

Structure and Characteristics:

The membrane electrolysis system has a compact and efficient design. It is built with high-quality materials to ensure durability and longevity. The unique ion exchange membrane allows for selective ion transport and prevents unwanted reactions. The system is easy to operate and maintain, with user-friendly controls and monitoring features.

Performance Parameters:

| Parameter | Value |

|---|---|

| Current Efficiency | ≥ 90% |

| Chlorine Gas Purity | ≥ 99% |

| Sodium Hydroxide Concentration | Variable |

| Energy Consumption | Depends on scale and capacity |

Economic Indicators:

| Indicator | Value |

|---|---|

| ROI (Return on Investment) | High |

| Payback Period | Short |

| Production Cost | Low |

Key Features and Advantages:

High current efficiency, leading to cost savings

Pure chlorine gas production with a high purity level

Variable sodium hydroxide concentration to meet different needs

Energy-efficient operation

Low production cost

Durable and reliable system

User-friendly controls and monitoring

Applications:

Membrane electrolysis for NaCl has a wide range of applications, including:

Chemical industry for chlorine gas and sodium hydroxide production

Water treatment for disinfection and pH adjustment

Electroplating industry for metal surface treatment

Paper manufacturing for bleaching processes

Medical and pharmaceutical industry

FAQ:

1. How long is the lifespan of the ion-exchange membrane?

The lifespan of the ion-exchange membrane depends on various factors such as operating conditions and maintenance. On average, it can last for several years before replacement is required.

2. Can the system be customized based on specific requirements?

Yes, our membrane electrolysis systems can be tailored to meet specific capacity and concentration needs. Please contact us to discuss your requirements.

3. Do you provide technical support and after-sales service?

Yes, we offer comprehensive technical support and one-stop after-sales service. Our team of experts is available to assist you with any queries or issues.

4. Are your products certified?

Yes, our membrane electrolysis systems are certified and comply with international standards for quality and safety.

Contact Us:

If you are considering a Membrane Electrolysis for the NaCl system, please feel free to contact us at yangbo@tjanode.com We are a professional manufacturer and supplier, offering high-quality products and excellent service.