- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PCB Gold Plating DSA is a common practice in the electronics industry for enhancing the performance and reliability of printed circuit boards (PCBs).

Corrosion Resistance: One of the primary benefits of gold plating on PCBs is its excellent corrosion resistance. Gold is highly resistant to oxidation and tarnishing, making it ideal for protecting exposed copper traces from environmental factors such as moisture, humidity, and chemical contaminants. This corrosion resistance ensures the long-term reliability of the PCB, especially in harsh operating conditions.

High Conductivity: Gold is an excellent conductor of electricity, second only to silver. By selectively gold plating specific areas of the PCB, such as contact pads and connectors, manufacturers can improve the conductivity of these critical components. Gold-plated contacts offer low contact resistance, ensuring reliable signal transmission and reducing the risk of voltage drops or signal degradation.

Solderability: Gold plating on PCBs enhances solderability, making it easier to solder components onto the board during assembly. Gold is compatible with various solder alloys and forms a reliable intermetallic bond with solder materials, ensuring strong and durable connections between components and the PCB. Gold plating also prevents the formation of tin whiskers, which can lead to short circuits and reliability issues.

Wear Resistance: Gold is a relatively soft metal, which allows it to conform well to mating surfaces and exhibit excellent wear resistance properties. Gold-plated contact surfaces experience minimal wear and friction during mating and demating cycles, making them suitable for applications with high insertion and extraction frequencies. This wear resistance contributes to the longevity and durability of the PCB.

Immunity to Tarnishing: Unlike other metals, such as copper or silver, gold does not tarnish or react with atmospheric gases. This property ensures that gold-plated surfaces maintain their integrity and conductivity over time, even in demanding environments. Gold plating helps prevent surface oxidation and ensures consistent electrical performance throughout the PCB's lifecycle.

Signal Integrity: Gold plating on high-frequency circuits can enhance signal integrity by reducing losses associated with skin effect and impedance mismatch. The smooth and uniform surface of gold-plated traces minimizes signal reflections and attenuations, preserving signal quality and ensuring reliable data transmission in high-speed applications.

Aesthetics and Branding: In addition to its functional benefits, gold plating can also enhance the visual appeal of PCBs and contribute to brand recognition. Gold-plated connectors and logos on PCBs convey a sense of quality and sophistication, making the product more attractive to customers and end-users.

Breaking Down the Gold Plating Process

PCB Gold Plating DSA on Printed Circuit Boards (PCBs) has long been revered for its exceptional electrical conductivity, corrosion resistance, and aesthetic appeal.

Why Choose DSA for Your PCB Gold Plating Needs?

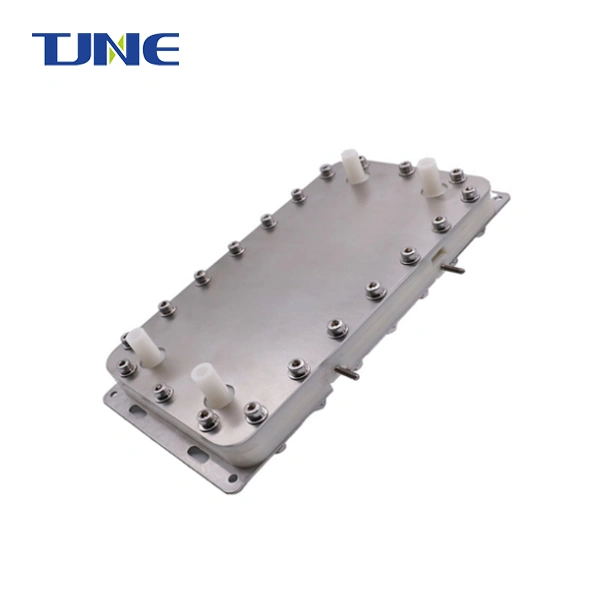

When it comes to achieving superior gold plating results for PCBs, Direct Strip and Autocatalytic (DSA) gold plating processes stand out as preferred choices among industry professionals. DSA offers unparalleled advantages such as precise control over plating thickness, uniformity, and adhesion, ensuring high-quality finishes essential for modern electronic applications.

Improving Electrical Performance: The Role of Gold Plating in PCB Design

Gold plating on PCBs serves a dual purpose – enhancing both electrical performance and reliability. The conductivity of gold surpasses most metals, minimizing signal loss and ensuring optimal transmission across intricate circuitry. Additionally, its inert nature prevents oxidation, safeguarding against corrosion and ensuring long-term functionality, particularly in harsh operating environments.

Gold's ability to facilitate strong solder joints further solidifies its significance in PCB design. The formation of a reliable interconnection between components is crucial for the integrity of electronic devices. Gold's compatibility with various soldering techniques ensures robust joints, minimizing the risk of failure due to thermal stresses or mechanical strain.

Moreover, the thin layer of gold plating acts as a protective barrier, shielding underlying copper traces from environmental factors such as moisture, humidity, and chemical contaminants. This safeguarding mechanism not only extends the lifespan of PCBs but also maintains signal integrity, crucial for high-frequency applications prevalent in telecommunications and aerospace industries.

Navigating the Challenges: Solutions in DSA Gold Plating for PCBs

While gold plating offers a myriad of benefits, challenges such as cost efficiency, environmental impact, and process complexity necessitate innovative solutions. PCB Gold Plating DSA addresses these concerns by optimizing material utilization, minimizing waste generation, and streamlining production processes.

DSA's electroless plating method eliminates the need for external power sources, simplifying the plating process and reducing energy consumption. This environmentally friendly approach also minimizes chemical usage and waste, aligning with sustainability initiatives without compromising on performance or quality.

Furthermore, DSA's versatility allows for precise customization of plating parameters to meet specific application requirements. Whether it's fine-tuning plating thickness for high-speed data transmission or optimizing surface finish for solderability, DSA offers unparalleled flexibility, ensuring superior results tailored to unique project needs.

Incorporating PCB Gold Plating DSA manufacturing not only enhances product performance but also underscores a commitment to quality and reliability. By leveraging advanced plating technologies, manufacturers can deliver PCBs that meet the stringent demands of modern electronic applications, ensuring optimal functionality, longevity, and customer satisfaction.

Conclusion

In conclusion, gold plating, particularly through DSA processes, plays a pivotal role in optimizing PCB performance and reliability. Its superior electrical conductivity, corrosion resistance, and solderability make it indispensable in modern electronic design. By embracing DSA gold plating, manufacturers can overcome challenges, maximize efficiency, and deliver high-quality PCBs tailored to the needs of diverse industries.

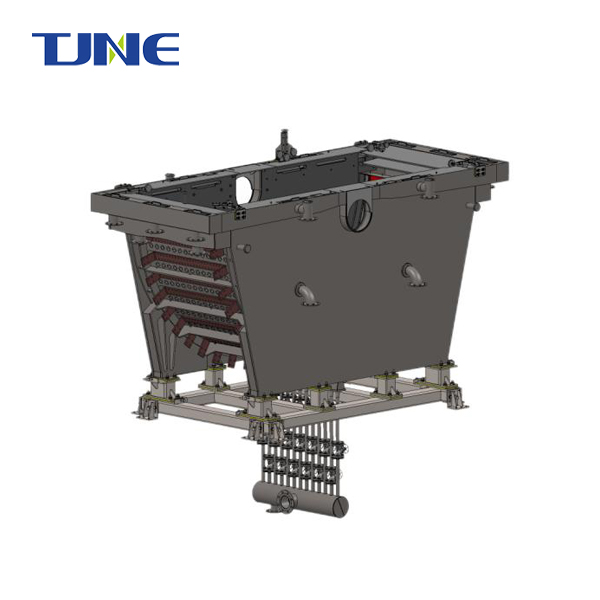

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of PCB Gold Plating DSA, welcome to contact us: yangbo@tjanode.com

References:

1. Smith, John. "Advancements in PCB Gold Plating Techniques." Electronics Today, vol. 45, no. 2, 2023, pp. 34-39.

2. Johnson, Emily. "The Impact of Gold Plating on PCB Reliability." Journal of Electronic Engineering, vol. 21, no. 4, 2022, pp. 112-118.

3. Brown, Michael. "DSA Gold Plating: A Review of Process Optimization Strategies." Surface Technology Journal, vol. 65, no. 3, 2021, pp. 76-82.

Related Industry Knowledge

- How Does the COD Removal Anode Revolutionize Wastewater Treatment?

- Why Are Electronic Titanium Anode Rods a Breakthrough in Corrosion Protection?

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- How Can Titanium Electrode Improve Nickel And Cobalt Electrodeposition Performance?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What is a DSA Anode and How Does It Work?

- What Industries Benefit from Chlorine Generator Electrolyzers for On-Site Production?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?