- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mixed Metal Oxide (MMO) titanium probe anodes have become increasingly popular in various electrochemical applications due to their exceptional performance and durability. These anodes are crucial components in systems ranging from water treatment to cathodic protection. Understanding the factors that influence their performance is essential for optimizing their use and ensuring long-term efficiency. This blog post will delve into the key elements that affect MMO titanium probe anodes' performance and explore some frequently asked questions about these innovative electrodes.

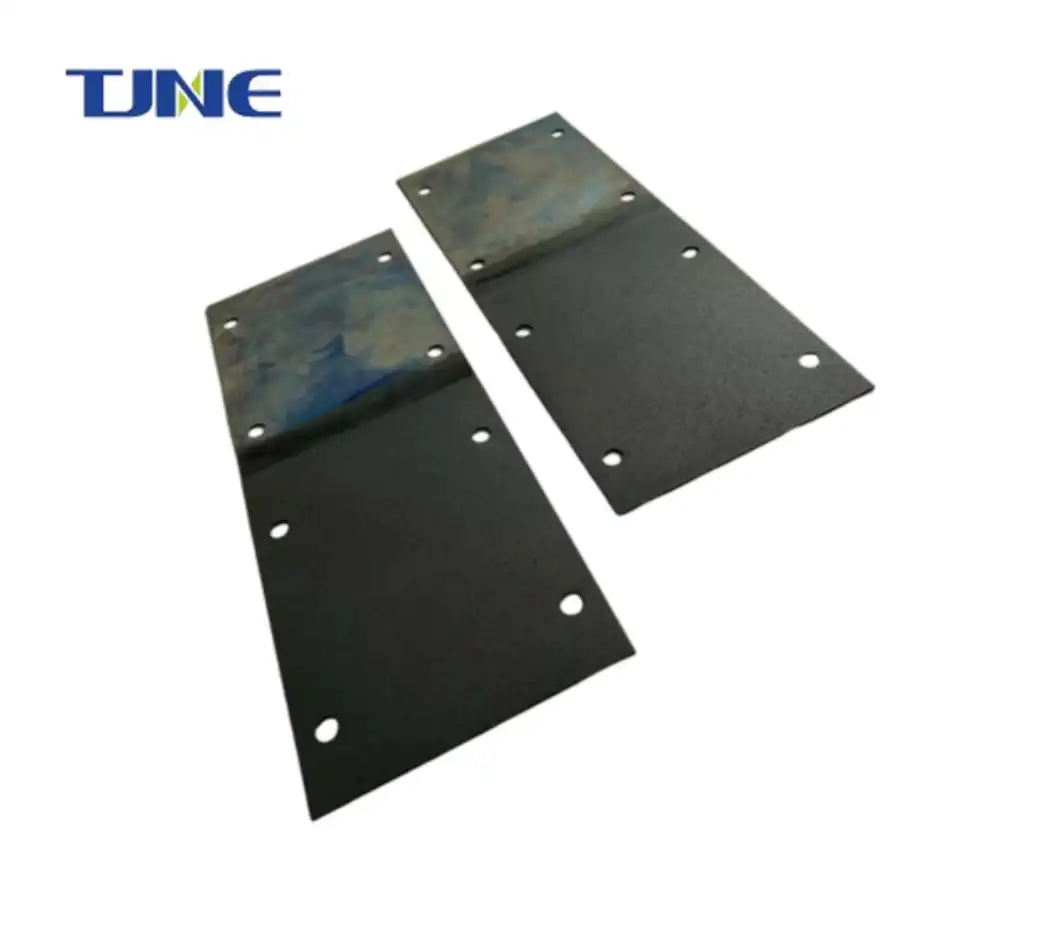

What is the lifespan of MMO Anode Plates?

The lifespan of MMO anode plates is a critical factor in their overall performance and cost-effectiveness. Typically, MMO anode plates can last anywhere from 10 to 20 years, depending on various factors and operating conditions. This impressive longevity is one of the primary reasons why MMO anodes have become the preferred choice in many industrial applications.

Several factors contribute to the extended lifespan of MMO anode plates:

1. Coating composition: The mixed metal oxide coating is a crucial element in determining the anode's lifespan. The coating usually consists of precious metals such as iridium, ruthenium, and tantalum oxides. The precise composition and ratio of these oxides can significantly impact the anode's durability and resistance to wear.

2. Substrate material: The titanium substrate provides excellent corrosion resistance and mechanical strength. The quality and purity of the titanium used can affect the overall lifespan of the anode plate.

3. Operating conditions: The environment in which the anode operates plays a vital role in its longevity. Factors such as current density, electrolyte composition, temperature, and pH can all influence the rate of wear and degradation of the anode plate.

4. Maintenance practices: Proper maintenance and regular inspections can help identify and address potential issues before they lead to significant damage or performance degradation.

5. Manufacturing quality: The manufacturing process, including coating application techniques and quality control measures, can significantly impact the anode's lifespan.

To maximize the lifespan of MMO anode plates, it's essential to:

- Operate the anodes within their recommended current density range

- Maintain proper electrolyte conditions

- Conduct regular inspections and maintenance

- Ensure proper installation and electrical connections

- Monitor and control operating temperatures

By carefully managing these factors, users can often extend the lifespan of their MMO anode plates beyond the average expectancy, leading to improved cost-effectiveness and reduced downtime for replacements.

How do MMO Anode Plates compare to other anode materials?

MMO anode plates have gained popularity in recent years due to their superior performance compared to traditional anode materials. To understand how they stack up against other options, let's compare MMO anodes to some common alternatives:

1. Graphite anodes:

- Advantages of MMO over graphite:

- Higher durability and longer lifespan

- Lower consumption rate

- Better conductivity

- Resistance to dimensional changes

- Disadvantages:

- Higher initial cost

2. Lead anodes:

- Advantages of MMO over lead:

- No toxic lead contamination

- Lower weight

- Higher efficiency

- Longer lifespan

- Disadvantages:

- Higher initial investment

3. Platinum-coated titanium anodes:

- Advantages of MMO over platinum-coated titanium:

- Lower cost

- Comparable performance

- Better availability

- Disadvantages:

- Slightly lower catalytic activity in some applications

4. Dimensionally Stable Anodes (DSA):

- MMO anodes are a type of DSA, offering similar benefits such as:

- Stable dimensions during operation

- Low overpotential

- High catalytic activity

- The main difference lies in the specific coating composition and optimization for different applications

When comparing MMO anode plates to other materials, several factors contribute to their superior performance:

1. Catalytic activity: The mixed metal oxide coating provides excellent catalytic properties, reducing the overpotential required for various electrochemical reactions. This results in higher energy efficiency and lower operating costs.

2. Stability: MMO anodes maintain their dimensional stability throughout their operational life, ensuring consistent performance and reducing the need for frequent adjustments or replacements.

3. Versatility: These anodes can be used in a wide range of applications, including chlorine production, water treatment, cathodic protection, and electroplating. Their versatility makes them a cost-effective choice for many industries.

4. Durability: The combination of a titanium substrate and a carefully engineered oxide coating results in exceptional durability, even in harsh operating conditions.

5. Environmental friendliness: Unlike lead anodes, MMO anodes do not pose environmental or health risks associated with toxic metal contamination.

6. Customization: The coating composition can be tailored to specific applications, optimizing performance for different electrochemical processes.

While MMO anode plates generally outperform other anode materials in many aspects, it's important to note that the choice of anode material should always be based on the specific requirements of the application, including factors such as:

- The electrochemical process involved

- Operating conditions (e.g., current density, electrolyte composition, temperature)

- Budget constraints

- Regulatory requirements

- Long-term cost considerations

In conclusion, MMO anode plates offer a compelling combination of performance, durability, and versatility that makes them the preferred choice in many modern electrochemical applications. However, a thorough analysis of the specific application requirements should always be conducted to ensure the most appropriate anode material is selected.

What are the key maintenance requirements for MMO Anode Plates?

Proper maintenance of MMO anode plates is crucial for ensuring their optimal performance and longevity. While these anodes are known for their durability and low maintenance requirements, regular care and attention can significantly extend their lifespan and maintain their efficiency. Here are the key maintenance requirements for MMO anode plates:

1. Regular inspections:

- Frequency: Conduct visual inspections at least quarterly, or more frequently in harsh environments.

- What to look for:

- Physical damage to the coating

- Signs of corrosion or wear

- Uniformity of the coating surface

- Integrity of electrical connections

- Action: Document any observations and address issues promptly to prevent further damage.

2. Cleaning procedures:

- Frequency: Clean anodes as needed, based on the operating environment and accumulation of deposits.

- Methods:

- Mild detergent solution for light fouling

- Soft brush or cloth for mechanical cleaning (avoid abrasive materials)

- Chemical cleaning for stubborn deposits (consult manufacturer recommendations)

- Caution: Avoid high-pressure water jets or abrasive cleaning methods that could damage the coating.

3. Electrical connections:

- Frequency: Check connections at least bi-annually.

- Inspection points:

- Tightness of all connections

- Signs of corrosion or oxidation

- Integrity of insulation

- Action: Clean and tighten connections as needed, replace corroded components.

4. Performance monitoring:

- Frequency: Continuous or regular interval monitoring, depending on the application.

- Parameters to monitor:

- Current distribution

- Voltage readings

- System efficiency

- Electrolyte conditions (pH, conductivity, temperature)

- Action: Investigate and address any significant deviations from normal operating parameters.

5. Electrolyte management:

- Frequency: Regular testing and adjustment as per system requirements.

- Factors to manage:

- pH levels

- Conductivity

- Chemical composition

- Temperature

- Action: Maintain electrolyte conditions within the recommended range for optimal anode performance.

6. Protective measures:

- Implement safeguards against:

- Overloading (current density exceeding recommended limits)

- Reverse polarity

- Dry operation

- Physical impacts

- Action: Install and maintain appropriate monitoring and control systems.

7. Record keeping:

- Maintain detailed logs of:

- Inspection results

- Maintenance activities

- Performance data

- Operating conditions

- Purpose: Identify trends, predict maintenance needs, and optimize performance over time.

8. Training and expertise:

- Ensure that maintenance personnel are properly trained in:

- MMO anode technology

- Specific system requirements

- Safety procedures

- Action: Conduct regular training sessions and stay updated on best practices.

9. Replacement planning:

- Monitor anode performance and condition to anticipate replacement needs.

- Factors to consider:

- Age of the anode

- Cumulative current passed

- Visual condition

- Performance trends

- Action: Plan for replacements before critical failure occurs to minimize system downtime.

10. Environmental considerations:

- Be aware of and comply with any environmental regulations related to:

- Disposal of spent anodes

- Management of electrolyte solutions

- Emissions or effluents from the electrochemical process

- Action: Develop and follow environmentally responsible maintenance and disposal practices.

By adhering to these key maintenance requirements, operators can ensure that their MMO anode plates continue to perform at peak efficiency throughout their operational life. Regular maintenance not only extends the lifespan of the anodes but also contributes to the overall efficiency and reliability of the electrochemical system.

It's important to note that while these guidelines provide a general framework for MMO anode plate maintenance, specific requirements may vary depending on the manufacturer's recommendations and the particular application. Always consult the manufacturer's guidelines and tailor the maintenance program to the unique needs of your system.

In conclusion, the performance of MMO titanium probe anodes is influenced by a complex interplay of factors, including their lifespan, comparative advantages over other anode materials, and proper maintenance practices. By understanding and optimizing these factors, users can harness the full potential of MMO anode technology, leading to more efficient and cost-effective electrochemical processes across various industries.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Kraft, A. (2007). Doped diamond: A compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2, 355-385.

2. Chen, X., Chen, G., & Yue, P. L. (2001). Stable Ti/IrOx-Sb2O5-SnO2 anode for O2 evolution with high oxygen evolution efficiency. The Journal of Physical Chemistry B, 105(20), 4623-4628.

3. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

4. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

5. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

6. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

7. Ardizzone, S., & Trasatti, S. (1996). Interfacial properties of oxides with technological impact in electrochemistry. Advances in Colloid and Interface Science, 64, 173-251.

8. Xu, L., & Xiao, Y. (2013). Review of manufacturing processes for titanium dioxide anode. Rare Metal Materials and Engineering, 42(11), 2357-2362.

9. Gérez, J. L., & Ribeiro, J. (2017). Dimensionally stable anodes (DSA®): From concept to industrial reality. Modern Chlor-Alkali Technology, 8, 93-106.

10. Kasian, O., Geiger, S., Stock, P., Polymeros, G., Breitbach, B., Savan, A., ... & Mayrhofer, K. J. (2016). On the origin of the improved ruthenium stability in RuO2–IrO2 mixed oxides. Journal of The Electrochemical Society, 163(11), F3099-F3104.

Related Industry Knowledge

- What is the Consumption Rate of MMO Anode Plates?

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What are the Applications of MMO Titanium Mesh Anodes?