- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

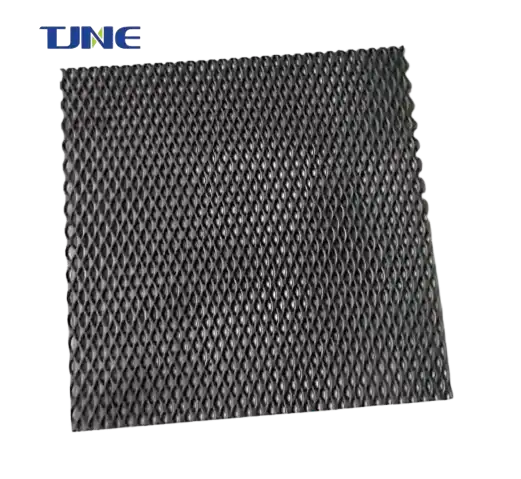

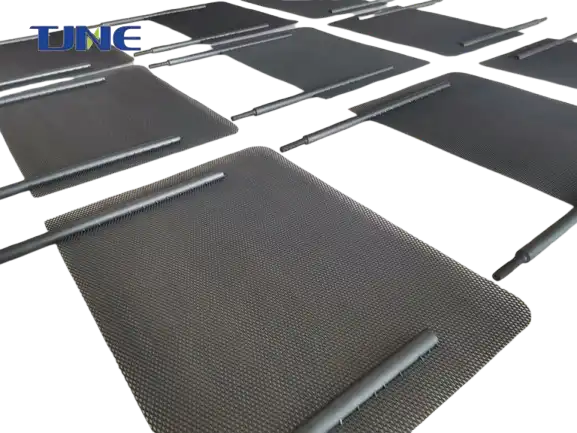

Mixed Metal Oxide (MMO) titanium mesh anodes have become increasingly popular in various industrial applications due to their exceptional performance and durability. These anodes are fabricated by coating a titanium mesh substrate with a mixture of precious metal oxides, typically including iridium, ruthenium, and tantalum. The resulting product combines the strength and corrosion resistance of titanium with the electrocatalytic properties of the metal oxides. This unique combination makes MMO titanium mesh anodes suitable for a wide range of applications, from cathodic protection to water treatment and electrolysis processes.

How do MMO titanium mesh anodes work in cathodic protection systems?

Cathodic protection is a technique used to prevent corrosion of metal structures exposed to corrosive environments, such as underground pipelines, offshore platforms, and marine vessels. MMO titanium mesh anodes play a crucial role in impressed current cathodic protection (ICCP) systems, where they serve as the anode component.

In an ICCP system, the MMO titanium mesh anode is connected to a DC power source and placed in close proximity to the metal structure that needs protection. The anode releases electrons into the surrounding electrolyte (such as soil or seawater), which then flow towards the protected structure (cathode). This flow of electrons creates a protective layer on the cathode's surface, effectively preventing corrosion.

The mesh structure of MMO titanium anodes offers several advantages in cathodic protection applications:

1. Large surface area: The mesh design provides a high surface area-to-volume ratio, allowing for efficient electron distribution and current output.

2. Uniform current distribution: The open structure of the mesh enables a more uniform distribution of current across the protected surface, ensuring comprehensive protection.

3. Low resistance: The titanium substrate offers low electrical resistance, minimizing power consumption and improving overall system efficiency.

4. Durability: MMO coatings on titanium mesh are highly resistant to wear and corrosion, ensuring long-term performance in harsh environments.

5. Flexibility: The mesh structure can be easily shaped and fitted to conform to complex geometries, making it suitable for protecting structures with irregular surfaces.

MMO titanium mesh anodes have proven particularly effective in protecting reinforced concrete structures, such as bridges, parking garages, and marine piers. In these applications, the mesh can be embedded within the concrete during construction or applied to the surface of existing structures. The open structure of the mesh allows for good bonding with the concrete while providing effective cathodic protection to the embedded steel reinforcement.

Furthermore, MMO titanium mesh anodes are widely used in offshore and subsea applications, where their corrosion resistance and durability are essential. They can be installed on offshore platforms, subsea pipelines, and other marine structures to provide long-lasting protection against the highly corrosive seawater environment.

What are the advantages of using MMO titanium mesh anodes in water treatment?

Water treatment is another field where MMO titanium mesh anodes have found significant applications. These anodes are extensively used in electrochemical water treatment processes, including electrocoagulation, electrooxidation, and electrochlorination. The unique properties of MMO titanium mesh anodes offer several advantages in water treatment applications:

1. Efficient contaminant removal: The electrocatalytic properties of the MMO coating enable efficient oxidation of various organic and inorganic contaminants in water. This includes the removal of heavy metals, organic pollutants, and pathogens.

2. Chlorine generation: In electrochlorination systems, MMO titanium mesh anodes can efficiently generate chlorine from chloride ions present in the water. This in-situ chlorine production is particularly useful for disinfection in swimming pools, cooling towers, and drinking water treatment plants.

3. Low energy consumption: The high electrocatalytic activity of MMO coatings, combined with the low electrical resistance of the titanium substrate, results in lower energy consumption compared to traditional electrode materials.

4. Chemical-free treatment: Electrochemical water treatment using MMO titanium mesh anodes often reduces or eliminates the need for chemical additives, making it an environmentally friendly alternative to conventional treatment methods.

5. Scalability: The mesh structure allows for easy scaling of treatment systems to accommodate various water flow rates and contaminant loads.

6. Long lifespan: The corrosion resistance and durability of MMO titanium mesh anodes contribute to a long operational life, reducing maintenance and replacement costs.

In municipal water treatment plants, MMO titanium mesh anodes are used in advanced oxidation processes to remove recalcitrant organic compounds and emerging contaminants that are not effectively removed by conventional treatment methods. The high oxidation potential of these anodes enables the breakdown of complex organic molecules into simpler, more biodegradable compounds.

Industrial wastewater treatment is another area where MMO titanium mesh anodes excel. They are particularly effective in treating wastewater from textile, pharmaceutical, and petrochemical industries, which often contain high levels of organic pollutants and colored compounds. The electrooxidation process using MMO anodes can achieve high removal rates for these contaminants, often surpassing the performance of traditional biological treatment methods.

Can MMO titanium mesh anodes improve the efficiency of electrolysis processes?

Electrolysis is a key process in various industrial applications, including metal recovery, chlor-alkali production, and hydrogen generation. MMO titanium mesh anodes have demonstrated significant potential in improving the efficiency and performance of these electrolysis processes.

In metal recovery applications, such as electrowinning of copper or zinc, MMO titanium mesh anodes offer several advantages:

1. High current efficiency: The electrocatalytic properties of the MMO coating enable high current efficiencies, leading to improved metal recovery rates.

2. Low overpotential: MMO anodes exhibit low overpotential for oxygen evolution, reducing energy consumption in the electrolysis process.

3. Resistance to passivation: The stable oxide coating prevents the formation of passivating layers on the anode surface, ensuring consistent performance over time.

4. Dimensional stability: Unlike traditional lead anodes, MMO titanium mesh anodes maintain their shape and dimensions during operation, leading to more uniform current distribution and consistent product quality.

In the chlor-alkali industry, where chlorine and sodium hydroxide are produced through the electrolysis of brine, MMO titanium mesh anodes have become the standard. Their ability to efficiently generate chlorine while resisting corrosion in the highly aggressive chlorine environment has led to significant improvements in process efficiency and product quality.

Hydrogen production through water electrolysis is an emerging field where MMO titanium mesh anodes show promise. While platinum-based catalysts are commonly used for the oxygen evolution reaction (OER) in water electrolysis, MMO coatings offer a more cost-effective alternative with comparable performance. The high surface area of the mesh structure, combined with the catalytic activity of the MMO coating, enables efficient oxygen evolution, thereby improving the overall efficiency of hydrogen production.

The use of MMO titanium mesh anodes in electrolysis processes also brings environmental benefits. Their long lifespan and resistance to wear reduce the frequency of replacement, minimizing waste generation. Additionally, the absence of toxic materials in their composition (unlike lead anodes) makes them a more environmentally friendly choice for industrial electrolysis applications.

In conclusion, MMO titanium mesh anodes have proven to be versatile and effective in a wide range of applications, from cathodic protection to water treatment and electrolysis processes. Their unique combination of properties, including high electrocatalytic activity, corrosion resistance, and durability, makes them an ideal choice for many industrial electrochemical applications. As research in this field continues, we can expect to see further improvements in MMO coatings and expanded applications for these innovative electrode materials.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd. please contact yangbo@tjanode.com.

References:

1. Kraft, A. (2007). Doped diamond: A compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2(5), 355-385.

2. Chen, X., Chen, G., & Yue, P. L. (2001). Stable Ti/IrOx-Sb2O5-SnO2 anode for O2 evolution with high oxygen evolution efficiency. The Journal of Physical Chemistry B, 105(20), 4623-4628.

3. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

4. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

5. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

6. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

7. Nidheesh, P. V., Zhou, M., & Oturan, M. A. (2018). An overview on the removal of synthetic dyes from water by electrochemical advanced oxidation processes. Chemosphere, 197, 210-227.

8. Sires, I., Brillas, E., Oturan, M. A., Rodrigo, M. A., & Panizza, M. (2014). Electrochemical advanced oxidation processes: today and tomorrow. A review. Environmental Science and Pollution Research, 21(14), 8336-8367.

9. Zoski, C. G. (Ed.). (2007). Handbook of Electrochemistry. Elsevier.

10. Pletcher, D., & Walsh, F. C. (1990). Industrial Electrochemistry. Springer Science & Business Media.

Related Industry Knowledge

- What Maintenance Practices are Best for MMO Mesh Anodes?

- How Efficient are MMO Mesh Anodes in Cathodic Protection Systems?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection