- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mixed Metal Oxide (MMO) Titanium Probe Anodes play a crucial role in protecting various structures and equipment from corrosion, particularly in challenging environments. These advanced anodes have become indispensable in industries ranging from oil and gas to marine applications, owing to their superior performance and longevity. In this blog post, we'll explore the importance of MMO Titanium Probe Anodes in corrosion protection and delve into some frequently asked questions about their applications and benefits.

How do MMO Titanium Probe Anodes Work in Cathodic Protection Systems?

Cathodic protection is a widely used technique to prevent corrosion in metal structures exposed to electrolytes, such as soil or water. MMO Titanium Probe Anodes are a key component in impressed current cathodic protection (ICCP) systems, which are designed to protect large structures or those in highly corrosive environments.

The working principle of MMO Titanium Probe Anodes in cathodic protection systems is based on electrochemistry. These anodes are connected to a power source and placed in the electrolyte near the structure to be protected. When current is applied, the anode releases electrons into the electrolyte, which then flow to the cathode (the protected structure). This flow of electrons shifts the electrical potential of the protected structure to a more negative value, effectively preventing the electrochemical reactions that cause corrosion.

MMO Titanium Probe Anodes are particularly effective in this role due to their unique composition and properties. The titanium substrate provides excellent mechanical strength and corrosion resistance, while the mixed metal oxide coating, typically consisting of precious metal oxides like iridium, ruthenium, or tantalum, offers exceptional electrochemical performance.

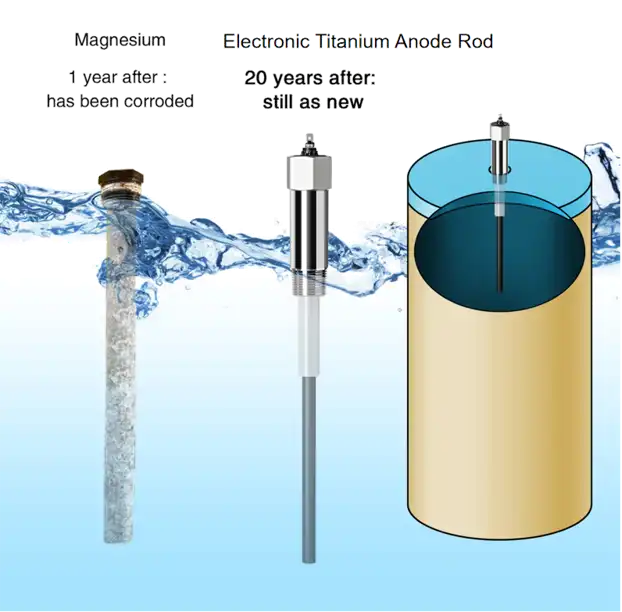

One of the key advantages of MMO Titanium Probe Anodes is their low consumption rate. Unlike traditional anodes made of materials like graphite or high-silicon cast iron, MMO anodes have a much longer lifespan, often lasting for decades with minimal degradation. This longevity is crucial in applications where frequent anode replacement would be costly or impractical, such as in offshore structures or buried pipelines.

Moreover, MMO Titanium Probe Anodes can operate at higher current densities compared to conventional anodes. This means they can provide more effective protection with a smaller anode surface area, making them ideal for applications where space is limited or where a high level of protection is required in a compact design.

The versatility of MMO Titanium Probe Anodes also contributes to their essential role in corrosion protection. They can be used in a wide range of environments, including seawater, freshwater, soil, and even concrete. This adaptability makes them suitable for protecting diverse structures such as ships, offshore platforms, underground storage tanks, and reinforced concrete structures.

What Are the Advantages of Using MMO Titanium Probe Anodes Over Traditional Anodes?

When comparing MMO Titanium Probe Anodes to traditional anode materials, several significant advantages become apparent, explaining why they have become essential in modern corrosion protection systems.

1. Longevity and Durability:

One of the most significant advantages of MMO Titanium Probe Anodes is their exceptional lifespan. Traditional anodes, such as graphite or high-silicon cast iron, tend to have higher consumption rates, requiring frequent replacement. In contrast, MMO anodes can last for decades, even in harsh environments. This longevity is due to the combination of the corrosion-resistant titanium substrate and the stable mixed metal oxide coating. The extended lifespan not only reduces maintenance costs but also ensures continuous protection for the structure, minimizing the risk of corrosion-related failures.

2. Higher Current Capacity:

MMO Titanium Probe Anodes can operate at much higher current densities compared to traditional anodes. This capability allows for more effective corrosion protection, especially in highly corrosive environments or for large structures. The ability to deliver higher currents from a smaller anode surface area makes MMO anodes particularly valuable in applications where space is limited or where a high level of protection is required.

3. Dimensional Stability:

Unlike traditional anodes that can change shape or size as they are consumed, MMO Titanium Probe Anodes maintain their dimensional stability throughout their operational life. This stability is crucial for maintaining consistent current distribution and ensuring uniform protection of the structure. It also simplifies system design and maintenance, as the anode's performance remains predictable over time.

4. Versatility in Various Environments:

MMO Titanium Probe Anodes demonstrate excellent performance across a wide range of environments, including seawater, freshwater, soil, and even concrete. This versatility makes them suitable for diverse applications, from offshore structures and ships to buried pipelines and reinforced concrete. Traditional anodes often have limitations in certain environments, requiring different materials for different applications.

5. Lower Weight and Compact Design:

The high efficiency and current capacity of MMO Titanium Probe Anodes mean that smaller anodes can be used to achieve the same level of protection as larger traditional anodes. This characteristic is particularly advantageous in applications where weight and space are critical factors, such as in marine vessels or offshore platforms.

6. Resistance to Passivation:

MMO coatings are highly resistant to passivation, a process where a layer of oxide forms on the anode surface, reducing its effectiveness. This resistance ensures that the anode continues to perform efficiently over its entire lifespan, maintaining consistent protection for the structure.

7. Environmental Considerations:

MMO Titanium Probe Anodes are considered more environmentally friendly compared to some traditional anodes. They do not release harmful substances into the environment as they operate, and their long lifespan means less frequent replacement and disposal of anodes.

8. Cost-Effectiveness in the Long Term:

While the initial cost of MMO Titanium Probe Anodes may be higher than traditional anodes, their long lifespan and low maintenance requirements make them more cost-effective in the long run. The reduced need for replacement, coupled with consistent performance, results in lower overall lifecycle costs for corrosion protection systems.

9. Improved System Design Flexibility:

The superior performance characteristics of MMO Titanium Probe Anodes offer greater flexibility in designing cathodic protection systems. Engineers can optimize anode placement and system configuration more effectively, leading to more efficient and reliable corrosion protection solutions.

10. Compatibility with Advanced Monitoring Systems:

MMO Titanium Probe Anodes are well-suited for integration with modern corrosion monitoring and control systems. Their stable performance characteristics make it easier to implement remote monitoring and automated control systems, enhancing the overall effectiveness of corrosion protection strategies.

How Are MMO Titanium Probe Anodes Manufactured and What Factors Influence Their Performance?

The manufacturing process of MMO Titanium Probe Anodes is a sophisticated procedure that directly influences their performance and longevity. Understanding this process and the factors affecting anode performance is crucial for professionals involved in corrosion protection.

Manufacturing Process:

1. Substrate Preparation:

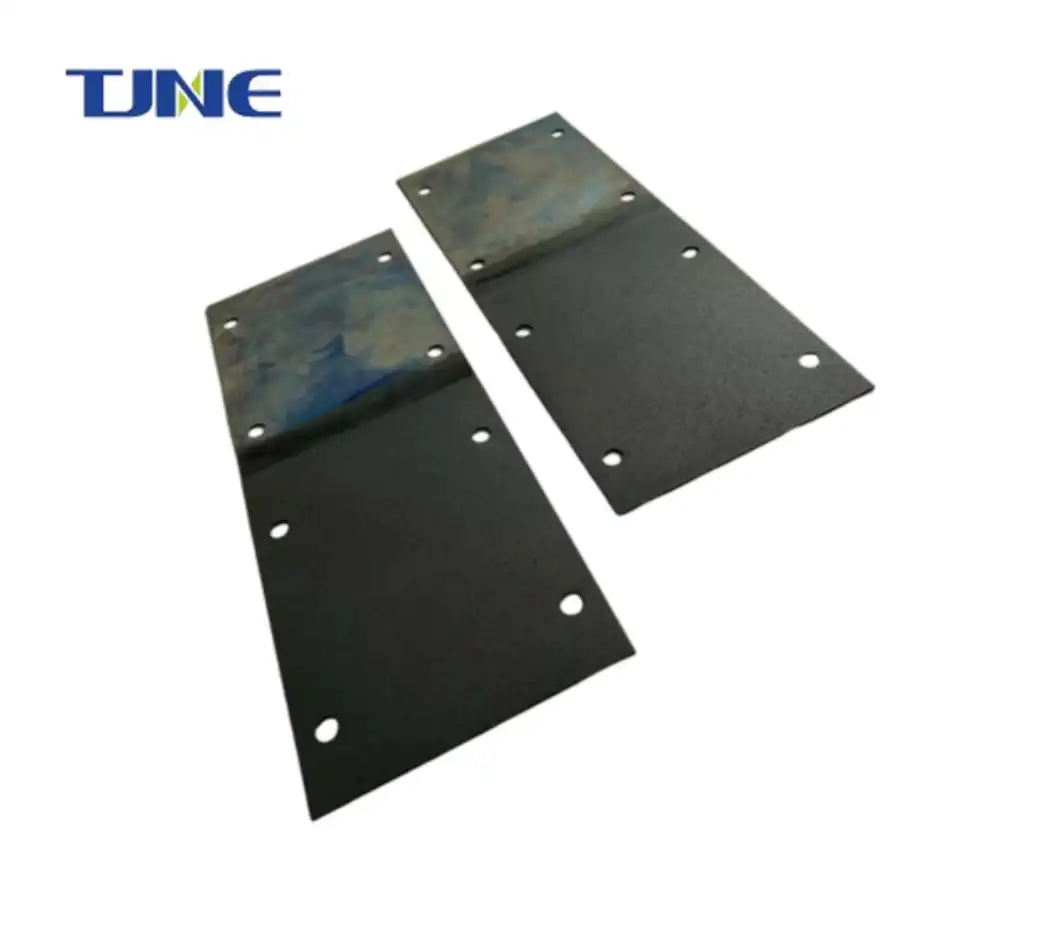

The process begins with high-grade titanium, chosen for its excellent corrosion resistance and mechanical properties. The titanium is typically formed into the desired shape, such as rods, tubes, or plates. The surface of the titanium is then carefully prepared to ensure optimal adhesion of the mixed metal oxide coating. This preparation often involves sandblasting or etching to create a slightly roughened surface.

2. Coating Application:

The mixed metal oxide coating is the heart of the anode's electrochemical performance. This coating typically consists of a mixture of precious metal oxides, such as iridium oxide, ruthenium oxide, and sometimes tantalum oxide. The coating is applied through a series of steps:

a. Precursor Solution Preparation: A solution containing the metal salts of the desired oxides is prepared.

b. Application: The precursor solution is applied to the titanium substrate. This can be done through various methods, including dipping, painting, or spraying.

c. Thermal Decomposition: The coated substrate is then subjected to high temperatures, typically in a furnace. This process causes the metal salts to decompose into their oxide forms, creating a tightly bonded coating on the titanium surface.

d. Multiple Layers: The process of application and thermal decomposition is often repeated several times to build up the desired thickness and composition of the coating.

3. Quality Control:

After the coating process, the anodes undergo rigorous quality control checks. These may include visual inspections, electrochemical testing to verify performance, and adherence tests to ensure the coating is properly bonded to the substrate.

4. Final Assembly:

Depending on the specific application, the anodes may be fitted with connection cables, insulators, or other components to prepare them for installation in cathodic protection systems.

Factors Influencing Performance:

Several key factors influence the performance of MMO Titanium Probe Anodes:

1. Coating Composition:

The specific mix of metal oxides in the coating significantly affects the anode's performance. Different compositions can be optimized for various environments and current densities. For example, higher iridium content generally improves performance in chloride-rich environments like seawater.

2. Coating Thickness and Uniformity:

The thickness of the mixed metal oxide coating affects both the anode's lifespan and its current distribution characteristics. A uniform coating ensures consistent performance across the entire anode surface.

3. Substrate Quality:

The purity and surface condition of the titanium substrate influence the adherence of the coating and the overall mechanical integrity of the anode.

4. Operating Environment:

The performance of MMO Titanium Probe Anodes can vary depending on the specific environment in which they are used. Factors such as electrolyte composition, temperature, and pH can all affect anode performance and lifespan.

5. Current Density:

The current density at which the anode operates significantly impacts its performance and lifespan. While MMO anodes can handle higher current densities than traditional anodes, there are still optimal ranges for different applications.

6. Manufacturing Process Control:

The precise control of each step in the manufacturing process, from substrate preparation to final coating, is crucial for producing high-quality, consistent anodes.

7. Quality of Electrical Connections:

Proper electrical connections between the anode and the power source are essential for optimal performance. Poor connections can lead to uneven current distribution and reduced effectiveness.

8. Design and Placement in the Cathodic Protection System:

The overall design of the cathodic protection system, including anode placement and spacing, influences how effectively the anodes perform their protective function.

9. Maintenance and Monitoring:

Regular monitoring of anode performance and timely maintenance can significantly extend the effective lifespan of MMO Titanium Probe Anodes.

Understanding these manufacturing processes and performance factors is crucial for engineers and technicians working with cathodic protection systems. It allows for better system design, more accurate prediction of anode lifespan, and optimization of corrosion protection strategies. As research and development in this field continue, we can expect further improvements in MMO Titanium Probe Anode technology, potentially leading to even more efficient and durable corrosion protection solutions.

In conclusion, MMO Titanium Probe Anodes have revolutionized the field of cathodic protection and corrosion control. Their unique combination of longevity, high performance, and versatility makes them essential in protecting critical infrastructure across various industries. As corrosion continues to pose significant challenges to modern engineering and construction, the role of MMO Titanium Probe Anodes in ensuring the safety, durability, and cost-effectiveness of structures in corrosive environments remains paramount. Their continued development and application will undoubtedly play a crucial role in addressing future corrosion challenges in an increasingly complex industrial landscape.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Shreir, L. L., Jarman, R. A., & Burstein, G. T. (Eds.). (1994). Corrosion: Metal/Environment Reactions. Butterworth-Heinemann.

2. Revie, R. W., & Uhlig, H. H. (2008). Corrosion and corrosion control: an introduction to corrosion science and engineering. John Wiley & Sons.

3. Baeckmann, W. V., Schwenk, W., & Prinz, W. (1997). Handbook of cathodic corrosion protection. Gulf Professional Publishing.

4. Roberge, P. R. (2008). Corrosion engineering: principles and practice. McGraw-Hill Professional.

5. Cicek, V. (2014). Cathodic protection: industrial solutions for protecting against corrosion. John Wiley & Sons.

6. Bardal, E. (2004). Corrosion and protection. Springer Science & Business Media.

7. Peabody, A. W. (2001). Control of pipeline corrosion. NACE International.

8. Hack, H. P. (Ed.). (1999). Designing cathodic protection systems for marine structures and vehicles. ASTM International.

9. Lazzari, L., & Pedeferri, P. (2006). Cathodic protection. Polipress.

10. Talbot, D., & Talbot, J. (2007). Corrosion science and technology. CRC Press.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?