- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electrodeposited Titanium Electrode for Nickel-Cobalt

Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).

Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.

Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.

Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.

Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.

What is electrodeposited titanium electrode for nickel-cobalt?

Our electrodeposited titanium electrode for nickel-cobalt is a high-quality electrode designed for various applications. It offers superior performance and durability, making it an ideal choice for industries requiring efficient electroplating processes.

Our electrode is specifically designed for electroplating nickel-cobalt alloys onto various substrates. It works on the principle of electrodeposition, where an electric current is passed through an electrolyte solution containing nickel and cobalt ions, causing them to deposit on the electrode surface. This electrode is made of titanium, which offers excellent corrosion resistance and stability.

Electrodeposited Titanium Electrode for Nickel-Cobalt Benefits:

Electroplating of nickel-cobalt alloys requires optimized anode material for efficient deposition. Our electrodeposited titanium anode offers key benefits for nickel-cobalt plating:

1.Pure titanium substrate provides excellent conductivity and corrosion resistance in nickel-cobalt plating baths.

2.Proprietary fabrication process creates a uniform, porous titanium coating ideal for anode activation.

3.Large surface area enables high plating speeds and current densities.

4.Porous structure allows rapid diffusion of ions preventing passivation.

5.Can be configured as plates, baskets or rods to suit tank geometries.

6.Dimensionally stable titanium bars prevent warping or damage.

7.Quick and easy periodic activation restores optimal plating performance.

8.Long lifetime provides reduced operation costs.

9.Compared to soluble/insoluble nickel anodes, our titanium anodes facilitate faster plating with lower power consumption while minimizing passivation issues. The operational and maintenance benefits ensure superior productivity and process control for nickel-cobalt alloy deposition tailored to customer requirements.

We supply OEMs and job shops worldwide with the industry's leading optimized titanium substrate anode technology for nickel-cobalt and other alloy plating systems.

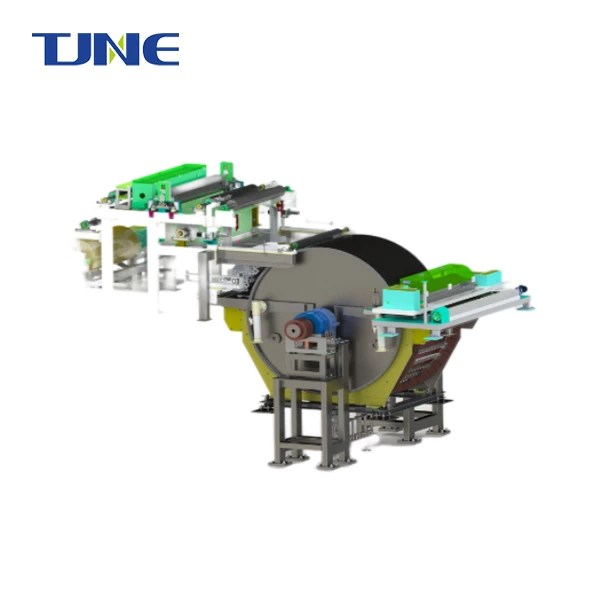

System Composition

The electrode consists of a titanium substrate with a high-quality coating that promotes efficient electrodeposition. Its unique structure and properties enable it to withstand harsh plating conditions and prolong the electrode's lifetime.

Performance Parameters

| Parameter | Value |

|---|---|

| Coating Thickness | 10-50 microns |

| Current Density | 50-2000 A/m2 |

| Working Temperature | 0-60°C |

| pH Range | 2-9 |

Technical Parameters

| Parameter | Value |

|---|---|

| Substrate Material | Titanium |

| Coating Material | Titanium Oxide |

| Coating Type | Anatase |

| Coating Structure | Uniform and dense |

Economic Indicators

| Indicator | Value |

|---|---|

| Price | Competitive |

| Lifespan | Long-lasting |

| Energy Efficiency | High |

Key Features

High-quality coating for efficient electrodeposition

Excellent corrosion resistance and stability

Durable and long-lasting

Compatible with various plating conditions

Applications

Our electrodeposited titanium electrode for nickel-cobalt is widely used in industries such as automotive, electronics, and aerospace for electroplating nickel-cobalt alloys onto various components. It is suitable for applications requiring high corrosion resistance, excellent wear resistance, and superior adhesion.

Electroplating nickel-cobalt alloys provide unique properties like high strength, corrosion and wear resistance. However, conventional anodes can limit plating speed, uniformity and bath stability. Our electrodeposited titanium anode overcomes these limitations for optimal nickel-cobalt plating.

Key application benefits:

1. High plating speed - Large surface area and rapid activation enables high current densities.

2. Improved uniformity - Porous structure prevents passivation for even deposition.

3. Superior bath stability - Pure titanium substrate has excellent compatibility.

4. Cost-effective - Long lifetime lowers operational costs.

5. Low power consumption - Efficient anode activation reduces energy usage.

6. Flexible configurations - Available as plates, baskets or rods.

7. Reliable performance - Dimensional stability prevents damage.

8. Easy maintenance - Periodic activation restores optimal conditions.

The electrodeposited titanium anode is proven worldwide in nickel-cobalt plating systems for oil & gas components, aerospace hydraulics, automotive parts, and decorative applications requiring wear and corrosion protection.

FAQ

1. Can this electrode be used for other electroplating processes?

Yes, our electrode can be used for various electroplating processes depending on the specific requirements.

2. What is the lifespan of this electrode?

Our electrode has a long lifespan, providing consistent performance over an extended period.

3. Can you provide technical support during installation and operation?

Yes, we offer comprehensive technical support to ensure the smooth installation and operation of our electrodes.

If you are interested in our electrodeposited titanium electrode for nickel-cobalt, please feel free to contact us at yangbo@tjanode.com. We are a professional manufacturer and supplier, offering high-quality products, strong technical expertise, and excellent after-sales service.

TJNE is committed to providing the best electrode solutions for your electroplating needs.