- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium anodes have revolutionized the electrochemical industry, playing a crucial role in various applications ranging from water treatment to metal production. These anodes, known for their exceptional corrosion resistance and longevity, have become indispensable in many electrochemical processes. The significance of titanium anodes lies in their ability to withstand harsh chemical environments while maintaining high electrical conductivity, making them ideal for use in chlor-alkali production, water electrolysis, and cathodic protection systems. As the demand for more efficient and sustainable electrochemical technologies grows, the importance of titanium anodes continues to increase, driving innovation and research in this field.

What are the advantages of using MMO anode plates in electrochemical processes?

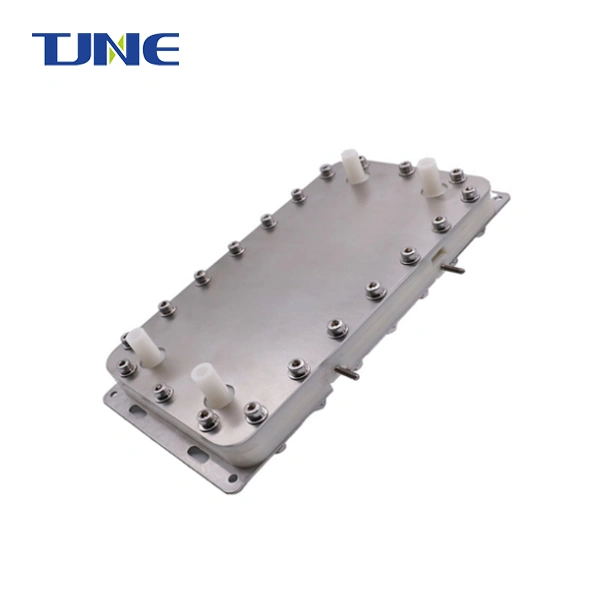

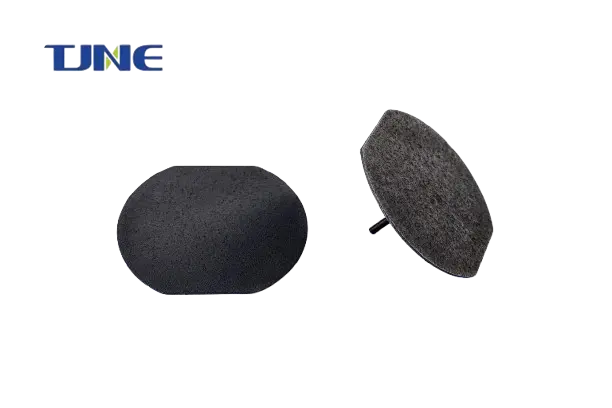

Mixed Metal Oxide (MMO) anode plates have gained significant popularity in the electrochemical industry due to their numerous advantages over traditional anodes. These plates consist of a titanium substrate coated with a mixture of metal oxides, typically including iridium, ruthenium, and tantalum oxides. The combination of these materials results in a highly effective and durable anode with several key benefits.

One of the primary advantages of MMO anode plates is their exceptional corrosion resistance. The titanium substrate provides an excellent base for the oxide coating, which forms a protective layer that prevents the underlying metal from corroding even in highly aggressive environments. This corrosion resistance translates to a significantly longer lifespan compared to traditional anodes, reducing maintenance costs and downtime in industrial applications.

Another crucial advantage of MMO anode plates is their low overpotential for oxygen and chlorine evolution reactions. This means that less energy is required to drive these reactions. The reduced energy consumption not only leads to cost savings but also contributes to a lower carbon footprint, making MMO anodes an environmentally friendly choice.

MMO anode plates also exhibit excellent dimensional stability, maintaining their shape and size even after prolonged use in harsh conditions. This stability ensures consistent performance and uniform current distribution, which is crucial for many electrochemical processes. Additionally, the oxide coating on MMO anodes has a high surface area, providing numerous active sites for electrochemical reactions and enhancing overall efficiency.

The versatility of MMO anode plates is another significant advantage. They can be customized with different oxide compositions to suit specific applications, allowing for optimized performance in various electrochemical processes.

Furthermore, MMO anode plates offer improved safety compared to some traditional anodes.

How does the lifespan of MMO anode plates compare to other anode materials?

The lifespan of Mixed Metal Oxide (MMO) anode plates is a critical factor in their growing popularity within the electrochemical industry. When compared to other anode materials, MMO anodes consistently demonstrate superior longevity, making them a cost-effective and reliable choice for many applications.

Traditional anode materials, such as graphite or lead, typically have shorter lifespans due to their susceptibility to corrosion and wear in harsh electrochemical environments. Graphite anodes, for example, can deteriorate rapidly in processes, leading to frequent replacements and increased operational costs. Lead anodes, while more durable than graphite, still face limitations in terms of their chemical stability and environmental concerns.

In contrast, MMO anode plates boast an impressive lifespan that can extend up to 10-15 years or even longer in some applications. This extended service life is primarily attributed to the combination of the corrosion-resistant titanium substrate and the stable oxide coating. The titanium base provides excellent structural integrity, while the mixed metal oxide layer offers exceptional resistance to chemical attack and erosion.

The longevity of MMO anode plates is particularly evident in cathodic protection, where they have largely replaced traditional anodes. In this application, MMO anodes can operate continuously for several years without significant degradation, whereas traditional anodes might require replacement every few months. This dramatic increase in lifespan not only reduces material costs but also minimizes production downtime associated with anode replacements.

The extended lifespan of MMO anode plates also contributes to their environmental sustainability. By reducing the frequency of replacements, these anodes help minimize waste generation and the environmental impact associated with the production and disposal of electrode materials. This aspect is becoming increasingly important as industries strive to adopt more sustainable practices.

It's worth noting that the actual lifespan of MMO anode plates can vary depending on several factors, including the specific application, operating conditions, and maintenance practices. However, even in the most demanding environments, MMO anodes consistently outperform other materials in terms of longevity.

What factors influence the performance of MMO anode plates in different applications?

The performance of Mixed Metal Oxide (MMO) anode plates in various applications is influenced by a complex interplay of factors. Understanding these factors is crucial for optimizing the design and operation of electrochemical systems that utilize MMO anodes.

One of the primary factors affecting MMO anode performance is the composition of the oxide coating. The specific combination and proportions of metal oxides in the coating can significantly impact the anode's catalytic activity, selectivity, and stability. However, the optimal composition may vary depending on the specific requirements of the application, such as the desired product, operating conditions, and longevity expectations.

The substrate preparation and coating technique also play crucial roles in MMO anode performance. The titanium substrate must be properly prepared to ensure strong adhesion of the oxide coating. Techniques such as sandblasting or etching are often employed to create a suitable surface profile. The method used to apply the oxide coating, whether it's thermal decomposition, electrodeposition, or other techniques, can affect the coating's structure, thickness, and uniformity, all of which influence the anode's performance and lifespan.

Operating conditions represent another significant set of factors that impact MMO anode performance. Parameters such as current density, electrolyte composition, temperature, and pH can all affect the anode's efficiency and longevity. For example, operating at excessively high current densities can accelerate the degradation of the oxide coating, while certain electrolyte compositions may promote or inhibit specific electrochemical reactions at the anode surface.

The presence of impurities in the electrolyte can also significantly influence MMO anode performance. Certain ions, such as calcium or magnesium, can form scale deposits on the anode surface, reducing its active area and efficiency. Other impurities may interact with the oxide coating, potentially altering its catalytic properties or accelerating its degradation.

The quality of electrical connections and current distribution across the anode surface is another critical factor. Uneven current distribution can lead to localized hot spots, accelerated wear, and reduced efficiency. Proper anode design, including the use of current distributors or optimized geometry, can help ensure uniform current distribution and maximize performance.

Maintenance practices also play a significant role in the long-term performance of MMO anode plates. Regular inspection, cleaning, and timely replacement of worn components can help maintain optimal performance and extend the anode's lifespan. In some applications, periodic reactivation of the anode surface through chemical or electrochemical treatments may be necessary to restore catalytic activity.

Finally, the specific application requirements and goals influence how MMO anode performance is evaluated and optimized.

In conclusion, the performance of MMO anode plates is a result of numerous interrelated factors, ranging from material composition and manufacturing techniques to operating conditions and maintenance practices. By carefully considering and optimizing these factors, engineers and operators can maximize the efficiency, longevity, and overall performance of MMO anodes in a wide range of electrochemical applications.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

2. Kraft, A. (2007). Doped diamond: a compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2(5), 355-385.

3. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

4. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

5. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

6. Chen, G. (2004). Electrochemical technologies in wastewater treatment. Separation and Purification Technology, 38(1), 11-41.

7. Rajeshwar, K., & Ibanez, J. G. (1997). Environmental electrochemistry: Fundamentals and applications in pollution sensors and abatement. Academic Press.

8. Chaplin, B. P. (2014). Critical review of electrochemical advanced oxidation processes for water treatment applications. Environmental Science: Processes & Impacts, 16(6), 1182-1203.

9. Simond, O., Schaller, V., & Comninellis, C. (1997). Theoretical model for the anodic oxidation of organics on metal oxide electrodes. Electrochimica Acta, 42(13-14), 2009-2012.

10. Katsaounis, A. (2010). Recent developments and trends in the electrochemical promotion of catalysis (EPOC). Journal of Applied Electrochemistry, 40(5), 885-902.

Related Industry Knowledge

- How Does Titanium Electrode Function in Electrochemical Processes?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- Electrochemical Innovation: The Role of Iridium-Tantalum Coated Titanium Anodes

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What Industries Rely on DSA Anodes for Electrochemical Processes?