- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

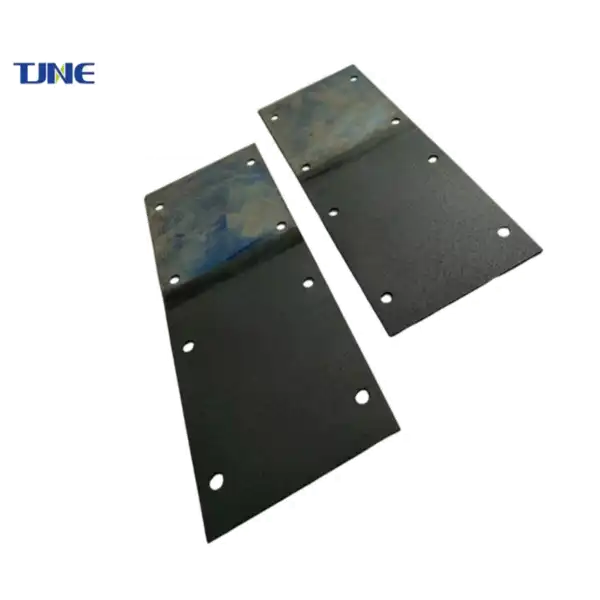

Ruthenium Iridium coated Titanium Anodes, also known as Mixed Metal Oxide (MMO) anodes, have become increasingly popular in various industrial applications due to their exceptional durability, efficiency, and electrochemical properties. These anodes are composed of a titanium substrate coated with a mixture of ruthenium and iridium oxides, creating a powerful and versatile electrode for electrochemical processes. The unique combination of these materials results in anodes that exhibit high catalytic activity, low overpotential, and excellent resistance to corrosion, making them ideal for use in demanding industrial environments.

How are Ruthenium Iridium coated Titanium Anodes manufactured?

The manufacturing process of Ruthenium Iridium coated Titanium Anodes is a complex and precise procedure that involves several key steps. The process begins with the preparation of the titanium substrate, which serves as the base for the anode. The titanium is carefully cleaned and etched to create a rough surface that promotes better adhesion of the coating.

Next, a precursor solution containing ruthenium and iridium compounds is prepared. This solution is typically a mixture of ruthenium chloride and iridium chloride, along with other additives that help control the coating properties. The precursor solution is then applied to the titanium substrate using various techniques, such as brush coating, dip coating, or spray coating.

After the coating is applied, the anodes undergo a thermal decomposition process. This involves heating the coated titanium in a controlled atmosphere at temperatures ranging from 400°C to 500°C. During this process, the precursor compounds decompose and form a stable oxide layer on the titanium surface. The heating process is carefully controlled to ensure the formation of a uniform and well-adhered coating.

Multiple coating and heating cycles may be performed to achieve the desired thickness and composition of the oxide layer. The final step often involves a post-treatment process to further enhance the electrochemical properties and durability of the anode.

The manufacturing process requires precise control over various parameters, including the composition of the precursor solution, coating thickness, and thermal treatment conditions. These factors significantly influence the performance and lifespan of the anodes. Advanced quality control measures, such as surface analysis techniques and electrochemical testing, are employed throughout the manufacturing process to ensure consistent product quality.

Continuous research and development efforts in the field have led to improvements in the manufacturing process, resulting in anodes with enhanced performance characteristics. For instance, some manufacturers have developed proprietary coating formulations and application techniques that optimize the distribution of ruthenium and iridium in the oxide layer, leading to improved catalytic activity and longer service life.

The manufacturing of Ruthenium Iridium coated Titanium Anodes is a specialized process that requires significant expertise and advanced equipment. As a result, these anodes are typically produced by specialized companies that have invested in the necessary technology and have developed proprietary techniques to create high-quality, long-lasting anodes for various industrial applications.

What are the key benefits of using Ruthenium Iridium coated Titanium Anodes in industrial processes?

Ruthenium Iridium coated Titanium Anodes offer numerous advantages that make them indispensable in many industrial processes. These benefits stem from the unique properties of the coating materials and their synergistic interaction with the titanium substrate.

One of the primary benefits is the exceptional durability of these anodes. The ruthenium-iridium oxide coating provides superior resistance to corrosion and erosion, even in highly aggressive chemical environments. This durability translates to longer service life, reduced maintenance requirements, and lower overall operational costs for industrial users.

The high catalytic activity of Ruthenium Iridium coated Titanium Anodes is another significant advantage. The mixed metal oxide coating exhibits excellent electrocatalytic properties, particularly for oxygen evolution reactions. This high catalytic activity allows for more efficient electrochemical processes, reducing energy consumption and improving overall process efficiency.

Low overpotential is another key benefit of these anodes. Overpotential refers to the additional voltage required to drive an electrochemical reaction beyond the thermodynamically determined potential. The ruthenium-iridium oxide coating minimizes this overpotential, allowing electrochemical reactions to proceed more readily and with less energy input. This characteristic is particularly valuable in applications where energy efficiency is a critical factor.

The stability of the coating under various operating conditions is another advantage. Ruthenium Iridium coated Titanium Anodes maintain their performance over a wide range of pH levels, temperatures, and current densities. This stability ensures consistent performance across different applications and operating conditions, making these anodes versatile tools in industrial electrochemistry.

Furthermore, these anodes offer excellent dimensional stability. Unlike some other anode materials that may deform or erode over time, Ruthenium Iridium coated Titanium Anodes maintain their shape and size throughout their operational life. This dimensional stability is crucial in applications where precise electrode geometry is essential for optimal performance.

The combination of titanium as the substrate material with the ruthenium-iridium oxide coating also results in anodes with a favorable weight-to-performance ratio. The lightweight nature of titanium, coupled with the high performance of the oxide coating, allows for the creation of large-scale anodes that are both effective and manageable in industrial settings.

Another benefit is the uniform current distribution provided by these anodes. The conductive oxide coating ensures that electrical current is distributed evenly across the anode surface, leading to more uniform electrochemical reactions. This characteristic is particularly important in applications such as electroplating, where uniform current distribution is essential for achieving consistent coating quality.

Lastly, Ruthenium Iridium coated Titanium Anodes offer environmental benefits compared to some alternative anode materials. They do not release harmful substances during operation and can contribute to more environmentally friendly electrochemical processes. This aspect is becoming increasingly important as industries strive to adopt more sustainable practices.

What are the primary applications of Ruthenium Iridium coated Titanium Anodes in water treatment?

Ruthenium Iridium coated Titanium Anodes play a crucial role in various water treatment applications, leveraging their unique properties to address a wide range of water quality issues. These anodes have become increasingly important in the face of growing global water scarcity and the need for more efficient and effective water treatment technologies.

One of the primary applications of these anodes in water treatment is in electrochlorination systems. Electrochlorination is a process used to generate chlorine on-site for water disinfection. Ruthenium Iridium coated Titanium Anodes are highly efficient in the electrolysis of saltwater or brine solutions to produce chlorine. This on-site generation eliminates the need for transportation and storage of hazardous chlorine gas, improving safety and reducing costs. The high catalytic activity of these anodes allows for efficient chlorine production even at low salt concentrations, making them suitable for both seawater and freshwater applications.

Another significant application is in advanced oxidation processes (AOPs) for water and wastewater treatment. AOPs are powerful treatment methods used to remove persistent organic pollutants, pharmaceuticals, and other difficult-to-treat contaminants from water. Ruthenium Iridium coated Titanium Anodes are used in electrochemical advanced oxidation processes (EAOPs) to generate highly reactive species such as hydroxyl radicals, which can break down complex organic compounds into simpler, less harmful substances. The high oxygen evolution overpotential of these anodes makes them particularly effective in generating these reactive species, leading to more efficient treatment processes.

In industrial wastewater treatment, these anodes are employed in electrocoagulation systems. Electrocoagulation is an electrochemical method used to remove suspended solids, emulsified oils, and heavy metals from wastewater. The Ruthenium Iridium coated Titanium Anodes serve as the inert electrode in these systems, facilitating the electrochemical reactions that lead to the formation of coagulants in situ. This process can effectively treat a wide range of industrial effluents, including those from the textile, food processing, and metal finishing industries.

Desalination is another area where Ruthenium Iridium coated Titanium Anodes find application. In electrodialysis and electrodeionization processes used for water desalination, these anodes play a crucial role in facilitating the movement of ions across selective membranes. The stability of these anodes in high-salinity environments and their resistance to chlorine make them ideal for long-term use in desalination plants.

These anodes are also used in electrochemical disinfection systems for swimming pools and cooling towers. In these applications, the anodes generate mixed oxidants directly in the water, providing effective disinfection without the need for chemical additions. This approach can lead to improved water quality, reduced chemical usage, and lower operational costs.

In the field of groundwater remediation, Ruthenium Iridium coated Titanium Anodes are employed in permeable reactive barriers and in-situ chemical oxidation systems. These electrochemical treatment methods can effectively remove contaminants such as chlorinated solvents, petroleum hydrocarbons, and heavy metals from groundwater. The durability and efficiency of these anodes make them suitable for long-term operation in subsurface environments.

Lastly, these anodes are finding increasing use in emerging water treatment technologies such as electro-Fenton processes and bioelectrochemical systems. In electro-Fenton processes, the anodes are used to generate hydrogen peroxide in situ, which then reacts with iron ions to produce highly reactive hydroxyl radicals for contaminant degradation. In bioelectrochemical systems, such as microbial fuel cells and microbial electrolysis cells, these anodes serve as efficient electron acceptors, supporting the growth of electroactive microorganisms for wastewater treatment and resource recovery.

The versatility and effectiveness of Ruthenium Iridium coated Titanium Anodes in these various water treatment applications highlight their importance in addressing current and future water quality challenges. As water treatment technologies continue to evolve, these anodes are likely to play an even more significant role in ensuring the availability of clean, safe water for diverse uses.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References

1. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

2. Chen, X., Chen, G., & Yue, P. L. (2001). Stable Ti/IrOx-Sb2O5-SnO2 anode for O2 evolution with high oxygen evolution efficiency. The Journal of Physical Chemistry B, 105(20), 4623-4628.

3. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

4. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

5. Chaplin, B. P. (2014). Critical review of electrochemical advanced oxidation processes for water treatment applications. Environmental Science: Processes & Impacts, 16(6), 1182-1203.

6. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

7. Sirés, I., Brillas, E., Oturan, M. A., Rodrigo, M. A., & Panizza, M. (2014). Electrochemical advanced oxidation processes: today and tomorrow. A review. Environmental Science and Pollution Research, 21(14), 8336-8367.

8. Feng, Y., Yang, L., Liu, J., & Logan, B. E. (2016). Electrochemical technologies for wastewater treatment and resource reclamation. Environmental Science: Water Research & Technology, 2(5), 800-831.

9. Radjenovic, J., & Sedlak, D. L. (2015). Challenges and opportunities for electrochemical processes as next-generation technologies for the treatment of contaminated water. Environmental Science & Technology, 49(19), 11292-11302.

10. Moreira, F. C., Boaventura, R. A., Brillas, E., & Vilar, V. J. (2017). Electrochemical advanced oxidation processes: a review on their application to synthetic and real wastewaters. Applied Catalysis B: Environmental, 202, 217-261.

Related Industry Knowledge

- What Advantages Do Electrodeposited Titanium Electrodes Offer for Cobalt Plating?

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- Why Should You Consider Titanium Electrodes for Copper Plating?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What Is a Chlorine Generator Electrolyzer and How Does It Operate?

- What is a DSA Anode and How Does It Work?

- What Industries Benefit from Chlorine Generator Electrolyzers for On-Site Production?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?