- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

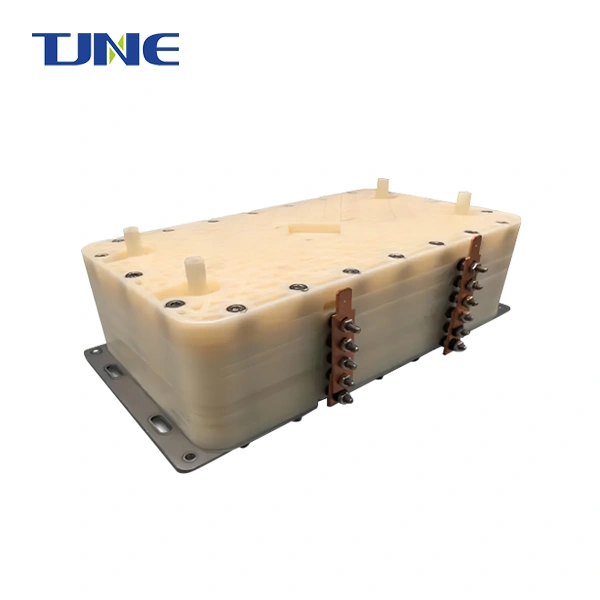

Mixed Metal Oxide (MMO) canistered wire anodes have revolutionized the field of cathodic protection, offering numerous advantages over traditional anode systems. These innovative anodes combine the durability of MMO technology with the practicality of a canister design, resulting in a highly effective solution for preventing corrosion in various industries. From offshore structures to underground pipelines, MMO canistered wire anodes have proven their worth in protecting valuable assets from the detrimental effects of electrochemical corrosion. In this blog post, we'll explore the key benefits of these advanced anode systems and why they've become increasingly popular in corrosion prevention strategies.

How do MMO canistered wire anodes improve corrosion protection in harsh environments?

In challenging environments where corrosion poses a significant threat to infrastructure and equipment, MMO canistered wire anodes offer superior protection compared to conventional anode systems. These anodes are specifically designed to withstand extreme conditions, making them ideal for use in offshore, marine, and underground applications.

One of the primary advantages of MMO canistered wire anodes in harsh environments is their exceptional durability. The mixed metal oxide coating, typically consisting of precious metals like iridium, ruthenium, and tantalum, is applied to a titanium substrate. This combination results in an anode with remarkable resistance to wear and chemical attack. Unlike traditional anodes that may deteriorate rapidly in aggressive environments, MMO anodes maintain their effectiveness over extended periods, ensuring consistent corrosion protection.

The canister design of these anodes further enhances their performance in challenging conditions. The wire anode is enclosed within a perforated metallic or non-metallic canister filled with a carbonaceous backfill material. This configuration serves multiple purposes:

1. Enhanced current distribution: The canister design allows for more uniform current distribution along the length of the anode, ensuring comprehensive protection of the target structure.

2. Mechanical protection: The canister shields the anode wire from physical damage, particularly in applications where the anode may be subjected to impacts or abrasion.

3. Improved anode-to-electrolyte interface: The carbonaceous backfill material provides a stable, conductive environment around the anode, facilitating efficient electron transfer and reducing the anode's operating resistance.

In offshore and marine environments, MMO canistered wire anodes excel at combating the corrosive effects of saltwater and marine organisms. Their resistance to chloride attack and ability to operate effectively in high-conductivity electrolytes make them an excellent choice for protecting offshore platforms, ship hulls, and port facilities. The canister design also helps prevent marine growth from interfering with the anode's performance, a common issue with exposed anode systems.

For underground applications, such as protecting buried pipelines or storage tanks, MMO canistered wire anodes offer significant advantages. The canister design helps maintain a consistent environment around the anode, even in soil conditions that may vary in moisture content or resistivity. This stability ensures that the anode continues to function effectively, regardless of seasonal changes or local soil variations.

Moreover, the low consumption rate of MMO anodes makes them particularly suitable for deep well applications, where anode replacement can be challenging and costly. Their ability to operate at high current densities without significant deterioration allows for the design of more compact and efficient cathodic protection systems in confined spaces.

The improved corrosion protection offered by MMO canistered wire anodes in harsh environments translates to several tangible benefits:

1. Extended asset life: By providing more effective and consistent protection, these anodes help extend the operational life of critical infrastructure and equipment.

2. Reduced maintenance: The durability of MMO anodes means less frequent replacement and maintenance, particularly valuable in remote or hard-to-access locations.

3. Enhanced safety: Improved corrosion protection reduces the risk of structural failures or leaks, contributing to safer operations in potentially hazardous environments.

4. Environmental protection: By preventing corrosion-related failures, MMO canistered wire anodes help mitigate the risk of environmental contamination, particularly in sensitive marine or underground ecosystems.

What are the cost-saving advantages of using MMO canistered wire anodes?

While the initial investment in MMO canistered wire anodes may be higher than traditional anode systems, their long-term cost-saving advantages make them an economically attractive option for many applications. These cost benefits stem from various factors related to their performance, longevity, and operational efficiency.

One of the most significant cost-saving aspects of MMO canistered wire anodes is their extended service life. Traditional anodes, such as high-silicon cast iron or graphite, typically have a lifespan of 10-15 years in many applications. In contrast, MMO anodes can last 20-30 years or even longer, depending on the operating conditions. This longevity translates to substantial savings in several ways:

1. Reduced replacement frequency: With a longer service life, the need for anode replacement is significantly diminished. This is particularly beneficial in applications where anode replacement is complex, time-consuming, or requires system shutdown.

2. Lower labor costs: Less frequent replacements mean reduced labor costs associated with anode installation and maintenance over the life of the cathodic protection system.

3. Minimized downtime: For critical infrastructure, such as pipelines or offshore platforms, extended anode life means fewer interruptions to operations for maintenance or replacement activities.

The high efficiency of MMO canistered wire anodes also contributes to cost savings. These anodes operate at lower resistance compared to traditional anodes, resulting in reduced power consumption for impressed current cathodic protection (ICCP) systems. Over the lifetime of the system, this improved energy efficiency can lead to significant reductions in operational costs, particularly in large-scale applications or regions with high electricity prices.

Furthermore, the canister design of these anodes offers additional economic benefits:

1. Simplified installation: The canister configuration allows for easier handling and installation compared to bare wire anodes, potentially reducing installation costs and time.

2. Improved backfill stability: The pre-packaged carbonaceous backfill in the canister ensures consistent anode performance without the need for complex on-site backfilling procedures, saving time and reducing the risk of installation errors.

3. Enhanced anode utilization: The canister design promotes more uniform anode consumption, maximizing the use of the anode material and potentially extending its effective life even further.

The cost advantages of MMO canistered wire anodes are particularly pronounced in challenging environments or remote locations. For offshore applications, for instance, the reduced need for anode replacement means fewer costly marine operations and less frequent need for specialized vessels or diving teams. In remote underground installations, such as cross-country pipelines, the extended anode life translates to fewer excavations and associated restoration work.

It's also worth considering the indirect cost savings associated with improved corrosion protection. By providing more reliable and consistent protection, MMO canistered wire anodes help prevent costly corrosion-related failures. These prevented failures can result in significant savings by avoiding:

1. Emergency repairs or replacements

2. Production losses due to unplanned shutdowns

3. Environmental cleanup costs in case of leaks or spills

4. Potential regulatory fines or legal liabilities

When evaluating the cost-effectiveness of MMO canistered wire anodes, it's crucial to consider the total cost of ownership over the entire life cycle of the cathodic protection system. While the initial investment may be higher, the long-term savings in replacement costs, maintenance, energy consumption, and prevented corrosion damage often result in a lower overall cost compared to traditional anode systems.

How do MMO canistered wire anodes enhance the longevity of cathodic protection systems?

The longevity of cathodic protection systems is crucial for ensuring continuous corrosion prevention and maintaining the integrity of valuable assets. MMO canistered wire anodes play a significant role in enhancing the durability and effectiveness of these systems, contributing to their extended operational life.

One of the primary ways MMO canistered wire anodes enhance system longevity is through their own exceptional lifespan. As mentioned earlier, these anodes can last 20-30 years or more, significantly outlasting many traditional anode materials. This extended anode life directly translates to increased longevity of the entire cathodic protection system. With fewer anode replacements required over the system's lifetime, there are fewer opportunities for system disruptions or potential weak points to develop.

The stability of MMO anodes also contributes to system longevity. Unlike some traditional anodes that may experience rapid consumption rates or unpredictable deterioration, MMO anodes provide a more consistent and predictable performance over time. This stability allows for more accurate long-term planning and maintenance scheduling, reducing the risk of unexpected system failures or protection gaps.

The canister design of these anodes further enhances system longevity in several ways:

1. Protected anode wire: By encasing the MMO wire in a canister, the anode is shielded from physical damage that could lead to premature failure. This is particularly important in environments where the anode may be exposed to impacts, abrasion, or other mechanical stresses.

2. Stable anode environment: The carbonaceous backfill within the canister provides a consistent, controlled environment for the anode. This stability helps maintain optimal anode performance over time, even if the surrounding soil or electrolyte conditions fluctuate.

3. Reduced anode passivation: The canister design, combined with the properties of MMO anodes, helps minimize the risk of anode passivation. Passivation can occur when an insulating layer forms on the anode surface, reducing its effectiveness. By maintaining a stable, conductive environment around the anode, the canister design helps ensure consistent anode output throughout its life.

The high efficiency of MMO canistered wire anodes also plays a role in system longevity. These anodes can operate at higher current densities compared to many traditional anodes, allowing for more compact and efficient system designs. This efficiency can lead to reduced stress on other system components, such as power supplies and cabling, potentially extending their operational life as well.

Moreover, the consistent performance of MMO canistered wire anodes helps maintain the effectiveness of the cathodic protection system over time. This consistency is crucial for preventing the formation of localized corrosion cells that could compromise the protected structure. By providing reliable, long-term protection, these anodes help prevent the accumulation of corrosion damage that could shorten the life of the protected asset.

The enhanced longevity provided by MMO canistered wire anodes also has implications for system design and management:

1. Simplified system upgrades: With longer-lasting anodes, system upgrades or modifications can be planned and implemented with less frequency, reducing the overall complexity of long-term system management.

2. Improved reliability: The extended life and consistent performance of these anodes contribute to increased system reliability, reducing the risk of protection failures and associated asset damage.

3. Easier compliance with regulations: Many industries are subject to strict regulations regarding corrosion protection. The long-term stability and predictable performance of MMO canistered wire anodes can make it easier to demonstrate ongoing compliance with these regulations.

4. Reduced life-cycle costs: While not directly related to technical longevity, the economic benefits of longer-lasting systems can influence decision-making around system maintenance and replacement, potentially leading to more sustainable long-term corrosion protection strategies.

In conclusion, MMO canistered wire anodes offer significant benefits in terms of corrosion protection in harsh environments, cost savings, and enhanced longevity of cathodic protection systems. Their durability, efficiency, and consistent performance make them an excellent choice for a wide range of applications, from offshore structures to underground pipelines. As industries continue to seek more effective and sustainable corrosion prevention solutions, MMO canistered wire anodes are likely to play an increasingly important role in protecting valuable assets and infrastructure.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References

1. Baeckmann, W. V., Schwenk, W., & Prinz, W. (1997). Handbook of cathodic corrosion protection. Gulf Professional Publishing.

2. Revie, R. W. (2015). Uhlig's corrosion handbook. John Wiley & Sons.

3. Cicek, V. (2014). Cathodic protection: industrial solutions for protecting against corrosion. John Wiley & Sons.

4. Roberge, P. R. (2008). Corrosion engineering: principles and practice. McGraw-Hill Education.

5. NACE International. (2013). Cathodic Protection Technologist Course Manual.

6. DNV GL. (2017). Recommended Practice DNVGL-RP-B401: Cathodic Protection Design.

7. Peabody, A. W. (2001). Peabody's control of pipeline corrosion. NACE International.

8. Shreir, L. L., Jarman, R. A., & Burstein, G. T. (1994). Corrosion: metal/environment reactions. Butterworth-Heinemann.

9. Tezdogan, T., & Demirel, Y. K. (2014). An overview of marine corrosion protection with a focus on cathodic protection and coatings. Brodogradnja: Teorija i praksa brodogradnje i pomorske tehnike, 65(2), 49-59.

10. Bushman, J. B. (2001). Galvanic anode cathodic protection system design. Bushman & Associates, Inc.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?

- What are the Applications of MMO Titanium Mesh Anodes?

Electrolyzers.webp)