- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

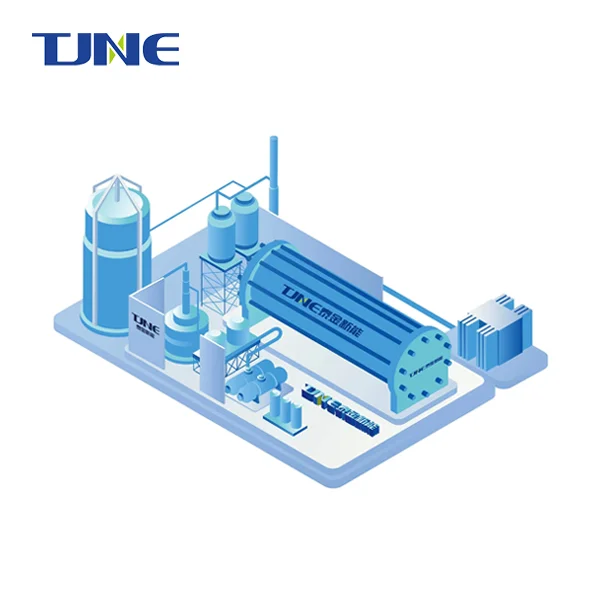

Titanium has gained significant attention in the field of electrochemistry due to its unique properties and potential applications as an anode material. As a lightweight, strong, and corrosion-resistant metal, titanium offers several advantages for use in electrochemical systems. However, its suitability as an anode depends on various factors and specific applications. This blog post will explore the characteristics of titanium as an anode material, focusing on its use with Dimensionally Stable Anode (DSA) coatings, and address some common questions about its performance and applications.

What are the advantages of using DSA coated titanium anodes?

DSA coated titanium anodes have revolutionized the field of electrochemistry and industrial electrolysis processes. These anodes offer a unique combination of benefits that make them highly desirable for various applications. Let's explore the advantages of using DSA coated titanium anodes in detail.

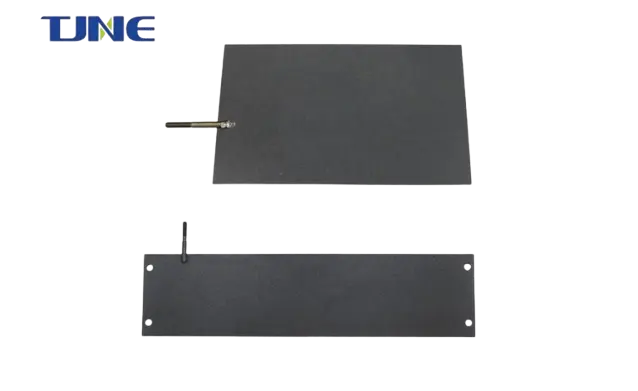

First and foremost, the use of titanium as the base material provides exceptional durability and longevity. Titanium is known for its excellent corrosion resistance, even in harsh chemical environments. When coated with DSA materials, such as mixed metal oxides, the anode's lifespan is significantly extended compared to traditional anode materials like graphite or lead.

The DSA coating itself brings several advantages to the table. These coatings typically consist of a mixture of noble metal oxides, such as ruthenium oxide, iridium oxide, or tantalum oxide. The composition of the coating can be tailored to specific applications, optimizing the anode's performance for different electrolysis processes. The coating provides a highly stable and active surface for electrochemical reactions, resulting in improved efficiency and reduced energy consumption.

One of the most significant advantages of DSA coated titanium anodes is their low overpotential for oxygen and chlorine evolution reactions. This characteristic allows for lower operating voltages, which translates to substantial energy savings in industrial processes. For example, in chlor-alkali production, DSA coated titanium anodes have been shown to reduce energy consumption by up to 15% compared to traditional graphite anodes.

Another benefit is the dimensional stability of these anodes. Unlike some other anode materials that may degrade or change shape over time, DSA coated titanium anodes maintain their dimensions throughout their operational life. This stability ensures consistent performance and eliminates the need for frequent adjustments or replacements in industrial settings.

The versatility of DSA coated titanium anodes is also worth noting. They can be used in a wide range of applications, including water treatment, metal electrowinning, cathodic protection, and the production of various chemicals. This versatility makes them a cost-effective solution for many industries, as the same type of anode can often be used across different processes with minimal modifications.

Furthermore, DSA coated titanium anodes offer excellent selectivity for desired reactions. The coating composition can be optimized to promote specific electrochemical reactions while suppressing unwanted side reactions. This selectivity leads to higher product purity and reduced waste generation in industrial processes.

Lastly, the environmental benefits of using DSA coated titanium anodes cannot be overlooked. Their long lifespan and energy efficiency contribute to reduced waste and lower carbon footprints in industrial operations. Additionally, these anodes do not release harmful substances into the environment during operation, making them a more sustainable choice compared to some traditional anode materials.

How does the performance of DSA coated titanium anodes compare to other anode materials?

When evaluating the performance of DSA coated titanium anodes, it's essential to compare them with other common anode materials used in electrochemical processes. This comparison helps us understand the unique advantages and potential limitations of DSA coated titanium anodes in different applications.

One of the primary competitors to DSA coated titanium anodes is graphite. Graphite anodes have been widely used in various electrochemical processes due to their low cost and good conductivity. However, DSA coated titanium anodes offer several advantages over graphite. Firstly, they have a much longer lifespan, often lasting 5-10 times longer than graphite anodes in similar operating conditions. This extended lifespan results in reduced maintenance and replacement costs over time.

In terms of efficiency, DSA coated titanium anodes generally outperform graphite anodes. The lower overpotential for oxygen and chlorine evolution reactions means that DSA coated titanium anodes can operate at lower voltages, resulting in significant energy savings. For example, in chlor-alkali production, the energy consumption can be reduced by up to 15% when switching from graphite to DSA coated titanium anodes.

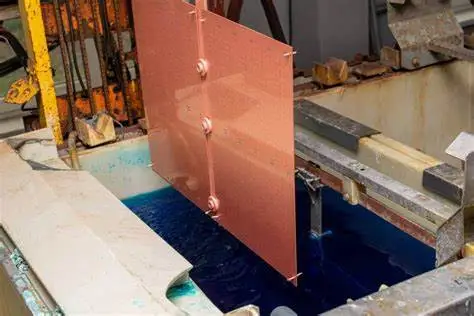

Another material often used for anodes is lead and lead alloys. While lead anodes are relatively inexpensive, they suffer from several drawbacks compared to DSA coated titanium anodes. Lead anodes are prone to corrosion and can contaminate the electrolyte and final product with lead ions. This contamination is particularly problematic in applications where product purity is crucial. DSA coated titanium anodes, on the other hand, do not introduce any metal contamination into the process, making them ideal for high-purity applications.

In terms of dimensional stability, DSA coated titanium anodes significantly outperform both graphite and lead anodes. Graphite anodes tend to erode over time, changing their shape and affecting the uniformity of current distribution. Lead anodes can also deform under certain operating conditions. The dimensional stability of DSA coated titanium anodes ensures consistent performance throughout their operational life, reducing the need for frequent adjustments or replacements.

When it comes to versatility, DSA coated titanium anodes have a clear advantage. They can be used in a wide range of pH conditions and electrolytes, whereas graphite and lead anodes are often limited to specific applications. This versatility makes DSA coated titanium anodes suitable for various industries and processes, from water treatment to metal electrowinning.

The selectivity of electrochemical reactions is another area where DSA coated titanium anodes excel. The composition of the DSA coating can be tailored to promote specific reactions while suppressing unwanted side reactions. This level of control is often not possible with graphite or lead anodes, leading to lower product purity and increased waste generation.

In terms of environmental impact, DSA coated titanium anodes are generally considered more environmentally friendly than both graphite and lead anodes. They do not release harmful substances during operation and their longer lifespan means less waste generation over time. The energy efficiency of DSA coated titanium anodes also contributes to a lower carbon footprint in industrial processes.

However, it's important to note that the initial cost of DSA coated titanium anodes is typically higher than that of graphite or lead anodes. This higher upfront cost can be a barrier to adoption in some cases. However, when considering the total cost of ownership, including energy savings, reduced maintenance, and longer lifespan, DSA coated titanium anodes often prove to be more cost-effective in the long run.

What factors affect the lifespan of DSA coated titanium anodes?

The lifespan of DSA coated titanium anodes is a critical factor in their overall performance and cost-effectiveness. While these anodes are known for their durability, several factors can influence their operational life. Understanding these factors is crucial for optimizing the use of DSA coated titanium anodes and maximizing their longevity in various applications.

One of the primary factors affecting the lifespan of DSA coated titanium anodes is the operating current density. Higher current densities generally lead to faster degradation of the DSA coating. This is because higher currents increase the rate of electrochemical reactions occurring at the anode surface, which can accelerate the wear of the coating. It's essential to operate the anodes within their recommended current density range to avoid premature failure. For instance, in chlor-alkali production, maintaining the current density below 3-4 kA/m² can significantly extend the anode's lifespan.

The composition of the electrolyte also plays a crucial role in determining the longevity of DSA coated titanium anodes. Certain ions present in the electrolyte can interact with the coating, potentially causing degradation over time. For example, the presence of fluoride ions can be particularly detrimental to some DSA coatings. Similarly, extreme pH conditions can affect the stability of the coating. It's important to consider the compatibility of the DSA coating composition with the specific electrolyte used in the process.

Temperature is another critical factor influencing the lifespan of these anodes. Higher operating temperatures generally accelerate the degradation of the DSA coating. This is due to increased rates of chemical and electrochemical reactions at elevated temperatures. Maintaining the operating temperature within the recommended range for the specific DSA coating can help prolong the anode's life. In some cases, cooling systems may be employed to control the temperature and extend the anode's lifespan.

The quality of the DSA coating itself is a crucial determinant of the anode's longevity. Factors such as the coating thickness, uniformity, and adherence to the titanium substrate all play a role in the anode's performance and lifespan. High-quality coatings applied using advanced techniques like thermal decomposition or electrodeposition tend to have better durability. Regular quality control and working with reputable manufacturers can ensure the use of high-quality DSA coated titanium anodes.

Mechanical stress is another factor that can affect the lifespan of these anodes. Physical impacts, vibrations, or excessive gas evolution can lead to cracking or flaking of the DSA coating. Proper handling during installation and maintenance, as well as designing the electrochemical system to minimize mechanical stress, can help preserve the integrity of the coating.

The presence of contaminants in the electrolyte can also impact the lifespan of DSA coated titanium anodes. Certain organic compounds or metal ions can adsorb onto the anode surface, potentially blocking active sites or causing unwanted side reactions. Regular electrolyte maintenance and filtration can help mitigate this issue and extend the anode's operational life.

Operational factors such as start-stop cycles and current reversals can also affect the longevity of DSA coated titanium anodes. Frequent power cycling can lead to thermal stress and potential delamination of the coating. Similarly, accidental current reversals can cause rapid degradation of the DSA coating. Implementing proper operational protocols and safeguards can help prevent these issues and extend the anode's lifespan.

The choice of DSA coating composition itself is a critical factor in determining the anode's lifespan for specific applications. Different coating compositions offer varying levels of stability and performance in different environments. For instance, ruthenium oxide-based coatings are often preferred for chlorine evolution, while iridium oxide-based coatings are more suitable for oxygen evolution in acidic media. Selecting the appropriate coating composition for the specific application can significantly impact the anode's longevity.

Lastly, regular maintenance and monitoring can play a significant role in extending the lifespan of DSA coated titanium anodes. Periodic inspections, performance evaluations, and timely recoating when necessary can help maintain the anode's efficiency and prolong its operational life. Implementing a comprehensive maintenance program can help identify and address potential issues before they lead to premature anode failure.

In conclusion, titanium can indeed be an excellent anode material when properly coated with DSA materials. The combination of titanium's inherent properties with the electrochemical advantages of DSA coatings results in anodes that offer superior performance, longevity, and versatility compared to many traditional anode materials. While the initial cost may be higher, the long-term benefits in terms of energy efficiency, reduced maintenance, and environmental friendliness often make DSA coated titanium anodes a cost-effective choice for many industrial applications. However, to fully realize these benefits, it's crucial to consider the various factors that can affect their lifespan and implement appropriate measures to optimize their performance and longevity.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

2. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

3. Chen, X., Chen, G., & Yue, P. L. (2001). Stable Ti/IrOx-Sb2O5-SnO2 anode for O2 evolution with high oxygen evolution efficiency. The Journal of Physical Chemistry B, 105(20), 4623-4628.

4. Panic, V. V., Nikolic, B. Z., & Dekanski, A. B. (2015). Oxygen evolution reaction on Ti/RuO2 coating: Effect of the substrate roughness. Russian Journal of Electrochemistry, 51(4), 386-394.

5. Kraft, A. (2007). Doped diamond: a compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2(5), 355-385.

6. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

7. Karlsson, R. K., & Cornell, A. (2016). Selectivity between oxygen and chlorine evolution in the chlor-alkali and chlorate processes. Chemical Reviews, 116(5), 2982-3028.

8. Morales-Acosta, D., Rodriguez, J. L., & Godinez, L. A. (2014). Mathematical modeling of dimensionally stable anodes in chlor-alkali membrane cells: Transport phenomena and thermodynamic analysis. Journal of Applied Electrochemistry, 44(11), 1307-1320.

9. Xu, L., & Xiao, Y. (2015). Review of manufacturing processes for titanium dioxide anode. Rare Metal Materials and Engineering, 44(1), 241-246.

10. Krstajić, N., Popović, M., Grgur, B., Vojnović, M., & Šepa, D. (2001). On the kinetics of the hydrogen evolution reaction on nickel in alkaline solution: Part I. The mechanism. Journal of Electroanalytical Chemistry, 512(1-2), 16-26.

Related Industry Knowledge

- What is the Lifespan of a DSA Coated Titanium Anode?

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- What is a DSA Coating Titanium Anode?

- What are DSA Anodes?

- What Industries Rely on DSA Anodes for Electrochemical Processes?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What is a DSA Anode and How Does It Work?

- What are DSA anodes?