- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

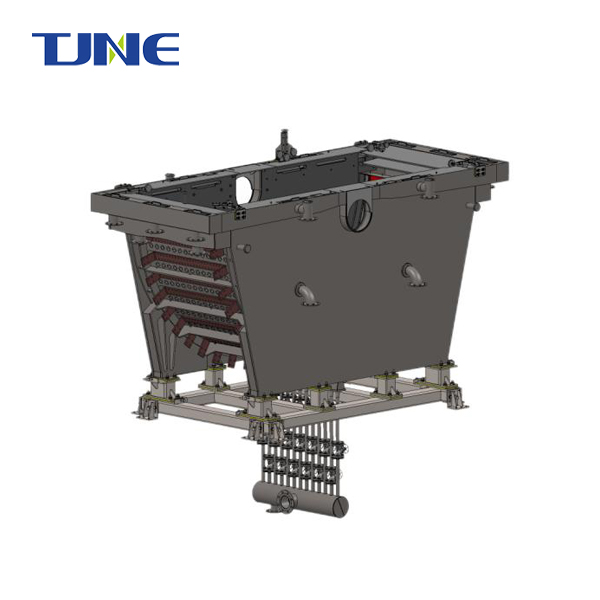

Electrodeposited Titanium Electrode for Cobalt

Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.

Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.

Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.

Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.

Product Details of electrodeposited titanium electrode for cobalt:

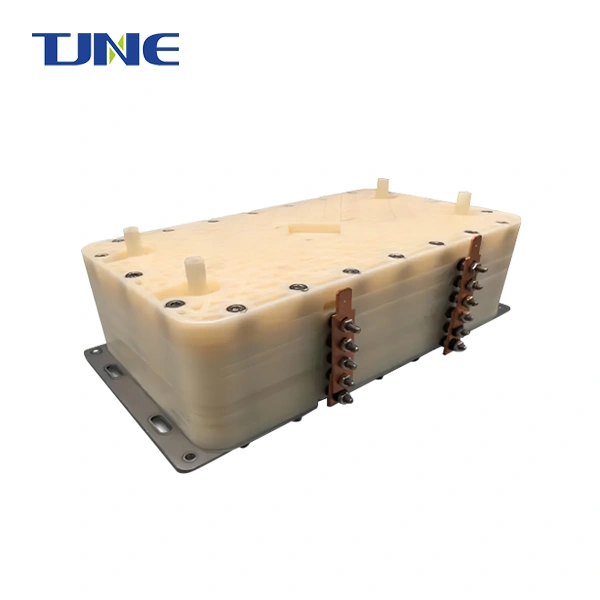

The electrodeposited titanium electrode for cobalt is a specialized product designed for various cobalt electroplating applications. The electrodeposited titanium electrode offers superior performance as an anode for cobalt electroplating processes. It consists of a high-purity titanium substrate bar or plate with a specially fabricated porous titanium coating. This coating is applied using a proprietary fabrication method to create a uniform, high surface area structure optimized for electroplating.

The titanium electrode provides excellent conductivity, activation efficiency, and dimensional stability in cobalt plating baths for optimal plating speed and uniformity. It is configured as durable plates or mesh baskets to suit the plating tank design and can be periodically reactivated to restore optimal performance. Compared to graphite and cobalt-based anodes, the electrodeposited titanium electrode facilitates faster, more efficient cobalt plating while minimizing power consumption and bath contamination.

Features:

High-quality electroplated titanium material

Efficient cobalt electroplating

Excellent chemical and reaction properties

Reliable performance

Specifications:

| Component | Description |

|---|---|

| Structure | Electrodeposited titanium electrode |

| Chemical Composition | Titanium |

| Working Principle | Electroplating of cobalt |

| Performance | Efficient and reliable |

| Technical Parameters | Dependent on specific application |

Economic Indicators:

| Parameter | Value |

|---|---|

| Price | Upon request |

| Delivery Time | Fast |

| Packaging | Secure and reliable packaging |

| Support | Comprehensive customer support and testing |

Functions:

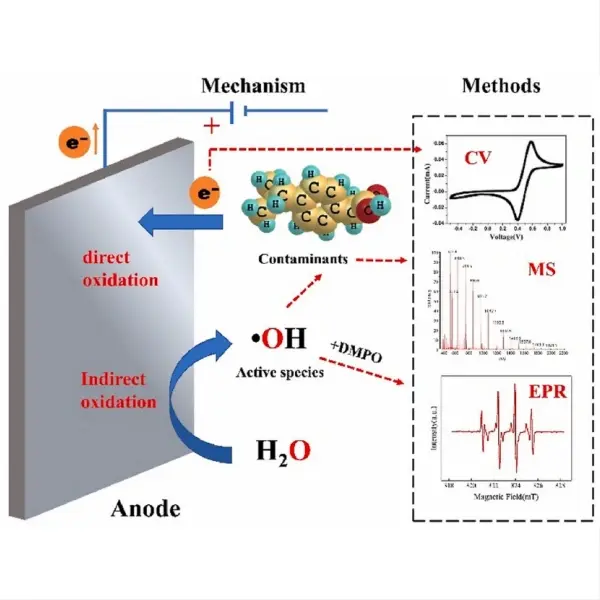

The electrodeposited titanium electrode for cobalt functions as the anode to provide uniform and efficient delivery of cobalt ions during the plating process. Its high-purity titanium substrate offers superior electrical conductivity to sustain high direct current densities needed for rapid plating. The porous titanium coating enables excellent anode activation and continuously renews the cobalt plating reaction. This prevents passivation or concentration gradients on the anode surface which hinder plating uniformity. The dimensional stability of the titanium substrate prevents damage from internal stresses during repeated plating cycles. The large surface area allows higher plating rates versus alternate anode materials. Periodic anode activation restores the optimal current distribution and plating efficiency as needed after extended use. This maintains a controlled cobalt ion flux to the cathode workpieces for consistent, high-quality cobalt deposition. The inert titanium material avoids contamination of the plating bath solution compared to soluble anodes. By supporting high speeds, efficiency, and process control, the electrodeposited titanium anode maximizes productivity and minimizes costs for cobalt electroplating.

Application Fields:

The electrodeposited titanium electrode is designed for cobalt electroplating systems across a range of industry sectors:

(1) Aerospace - Cobalt coatings for corrosion and wear protection

(2)Automotive - Decorative cobalt plating for trim components

(3)Medical - Cobalt-chromium coatings for orthopedic implants

(4)Petrochemical - Valves, pumps, and fittings requiring cobalt alloy plating

(5)Electronics - Magnetic cobalt alloys for data storage media

FAQ:

Q: What is the delivery time for the electrode?

Q: Can I use this electrode for other electroplating processes?

Q: How can I contact you for further inquiries or orders?

A: We offer fast delivery within the specified timeframe.

A: The electrode is specifically designed for cobalt plating applications.

A: Please feel free to email us at yangbo@tjanode.com.

About Us:

TJNE is a professional manufacturer and supplier of electrodeposited titanium electrodes for cobalt. We have strong technical expertise and provide a one-stop solution for your electroplating requirements. Our products are certified and thoroughly tested, ensuring top-notch quality. We offer fast delivery and secure packaging. Contact us today!