- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium anodes play a crucial role in modern swimming pool disinfection systems, offering an efficient and low-maintenance solution for keeping pool water clean and safe. These anodes are a key component in salt chlorination systems, which have gained popularity among pool owners for their ability to produce chlorine on-site, reducing the need for manual chemical additions. The longevity of titanium anodes is a common concern for pool owners and operators, as it directly impacts the system's effectiveness and maintenance requirements.

How do titanium anodes work in swimming pool chlorination systems?

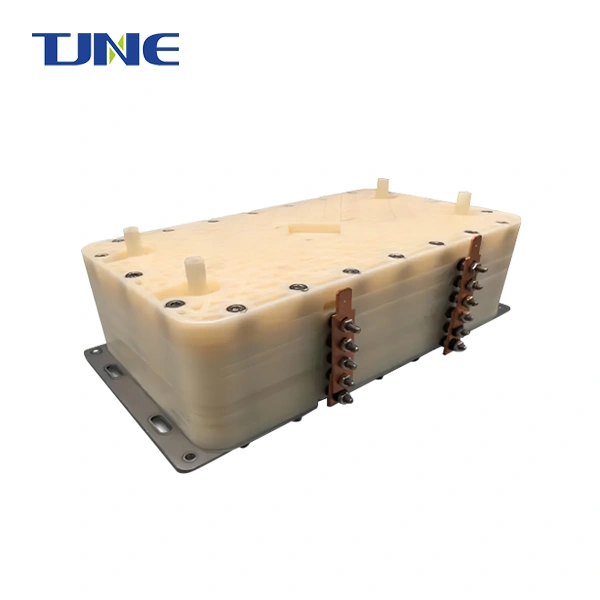

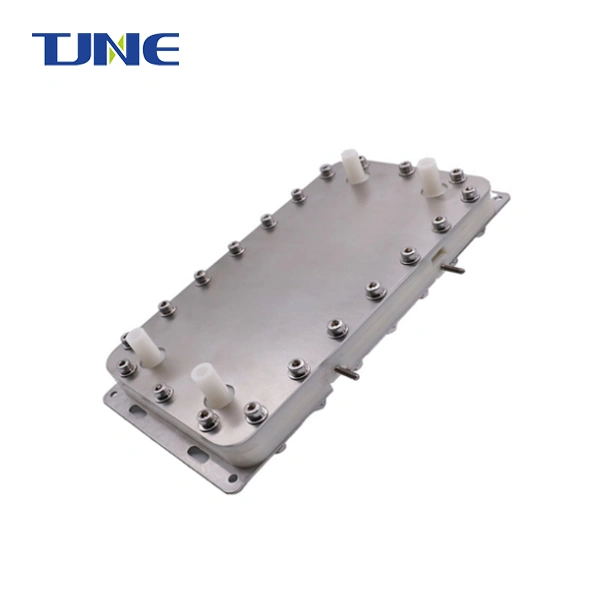

Titanium anodes are at the heart of salt chlorination systems, which have revolutionized swimming pool maintenance. These systems work by converting dissolved salt (sodium chloride) in the pool water into sodium hypochlorite through a process called electrolysis. The titanium anode, along with its counterpart, the cathode, forms the electrolytic cell where this conversion takes place.

When an electric current is passed through the cell, it triggers a series of chemical reactions. The titanium anode, coated with special catalytic materials such as ruthenium or iridium oxide, facilitates the oxidation of chloride ions from the dissolved salt. This process produces hypochlorous acid, which is the active sanitizing agent in the pool water. The hypochlorous acid effectively eliminates bacteria, algae, and other harmful microorganisms, keeping the pool water clean and safe for swimmers.

The use of titanium as the base material for these anodes is not arbitrary. Titanium possesses excellent corrosion resistance properties, which is crucial in the harsh, chlorine-rich environment of a swimming pool. The catalytic coating on the titanium surface enhances its electrochemical properties, making it highly efficient in the chlorine generation process.

One of the key advantages of titanium anodes in salt chlorination systems is their ability to produce a steady supply of sodium hypochlorite. This continuous production helps maintain a consistent chlorine level in the pool, avoiding the peaks and valleys often associated with manual chlorine addition. As a result, swimmers experience fewer irritations typically caused by fluctuating chlorine levels, such as red eyes or skin irritation.

Moreover, the salt chlorination process using titanium anodes is more environmentally friendly compared to traditional chlorine addition methods. It reduces the need for storing and handling hazardous chemicals, as the sodium hypochlorite is produced on-site from the salt already dissolved in the pool water. This not only enhances safety but also contributes to a more sustainable pool maintenance approach.

The efficiency of titanium anodes in chlorine production also translates to cost savings for pool owners. While the initial investment in a salt chlorination system might be higher than traditional chlorine dosing systems, the reduced need for chemical purchases and lower maintenance requirements often result in long-term savings.

What factors affect the lifespan of titanium anodes in swimming pools?

The lifespan of titanium anodes in swimming pool systems can vary significantly based on several factors. Understanding these factors is crucial for pool owners and operators to maximize the longevity of their chlorination systems and ensure optimal performance.

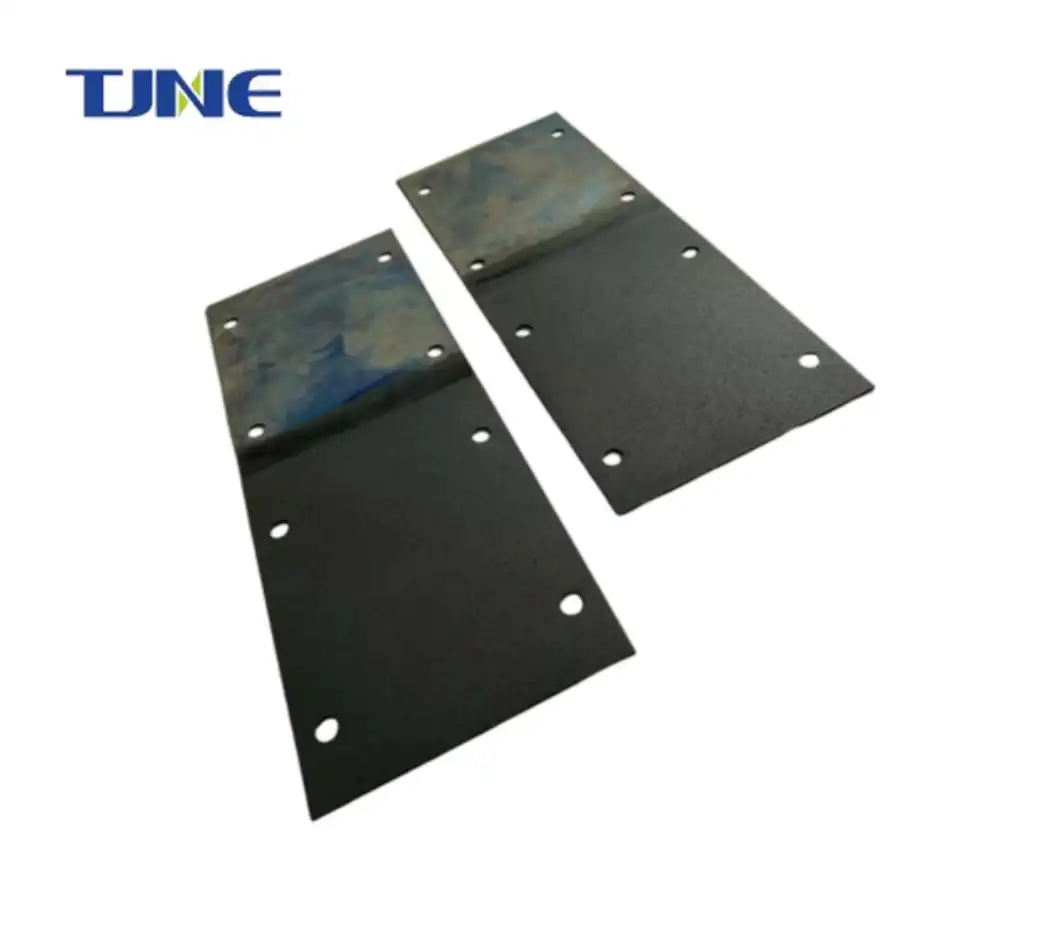

One of the primary factors affecting titanium anode lifespan is the quality of the anode itself. High-quality anodes, manufactured with precision and coated with durable catalytic materials, tend to last longer than lower-quality alternatives. The thickness and composition of the catalytic coating play a significant role in determining the anode's durability. Reputable manufacturers often provide warranties or estimated lifespans for their anodes, which can serve as a good indicator of quality.

Water chemistry is another critical factor influencing anode longevity. Maintaining proper water balance, including pH, alkalinity, and calcium hardness, is essential not only for swimmer comfort but also for preserving the anode. Imbalanced water chemistry, particularly high pH levels or excessive calcium hardness, can lead to scale formation on the anode surface. This scaling can reduce the anode's efficiency and potentially shorten its lifespan.

The salt concentration in the pool water also affects anode performance and longevity. Most salt chlorination systems are designed to operate within a specific range of salt levels, typically between 2700-3400 parts per million (ppm). Operating the system outside this range, especially with insufficient salt, can strain the anode and potentially lead to premature wear.

Usage patterns and system settings play a significant role in anode lifespan. Pools that require higher chlorine output due to heavy use, exposure to sunlight, or other factors may experience faster anode wear. Similarly, running the chlorination system at maximum output for extended periods can accelerate anode degradation. Proper sizing of the chlorination system to match the pool's needs and using appropriate output settings can help prolong anode life.

Environmental factors, such as climate and pool location, can indirectly impact anode longevity. Pools in warmer climates or those exposed to more sunlight may require higher chlorine production, potentially leading to increased anode wear. Additionally, outdoor pools exposed to the elements may face more challenging conditions compared to indoor pools.

Maintenance practices significantly influence anode lifespan. Regular inspection and cleaning of the anode can prevent the buildup of scale and debris that might impair its function. Some systems come with self-cleaning or reverse polarity features that help maintain anode cleanliness, but periodic manual inspection is still recommended.

The overall design and quality of the salt chlorination system also play a role in anode longevity. Systems with advanced features such as flow sensors, temperature compensation, and adaptive chlorine production can help optimize anode performance and extend its life by ensuring it operates under ideal conditions.

Lastly, the presence of certain metals in the pool water, particularly copper and iron, can affect anode performance. These metals can interfere with the electrolysis process and potentially accelerate anode wear. Using a metal sequestrant and maintaining proper water balance can help mitigate these issues.

How can pool owners extend the life of their titanium anodes?

Extending the life of titanium anodes is a key concern for pool owners looking to maximize their investment in salt chlorination systems. By implementing proper maintenance practices and being mindful of operating conditions, pool owners can significantly increase the longevity of their anodes.

Regular water testing and maintenance of proper chemical balance is perhaps the most critical step in extending anode life. Maintaining the pH between 7.2 and 7.6, alkalinity between 80 and 120 ppm, and calcium hardness between 200 and 400 ppm helps prevent scale formation on the anode surface. Consistently balanced water not only protects the anode but also ensures optimal chlorine production efficiency.

Monitoring and maintaining the correct salt level is equally important. Most manufacturers recommend keeping salt levels between 2700-3400 ppm, but it's essential to refer to the specific system's guidelines. Using a reliable salt testing method and adding salt as needed helps prevent the system from working harder than necessary, which could lead to premature anode wear.

Implementing a regular cleaning routine for the anode can significantly extend its lifespan. While many modern systems include self-cleaning features, periodic manual inspection and cleaning can catch any issues early. Gently removing any visible scale or debris using a soft brush or cloth can help maintain the anode's efficiency. However, it's crucial to avoid using harsh chemicals or abrasive materials that could damage the catalytic coating.

Proper winterization of the pool and chlorination system in colder climates is essential for anode preservation. Following the manufacturer's guidelines for winter shutdown and storage can prevent damage from freezing temperatures and extend the overall lifespan of the system, including the anodes.

Optimizing the chlorinator's settings based on pool usage and environmental factors can help prevent unnecessary wear on the anodes. During periods of lower pool use or cooler weather, reducing the chlorine output can conserve anode life without compromising water quality. Some advanced systems offer automated adjustment features that optimize chlorine production based on factors like water temperature and pool cover status.

Using a pool cover when the pool is not in use can indirectly contribute to anode longevity. Covers reduce chlorine loss due to UV exposure and minimize debris entering the pool, potentially allowing for lower chlorine production settings and less strain on the anodes.

Ensuring proper water circulation and filtration is another key factor in extending anode life. Efficient circulation helps distribute the chlorine produced by the anodes evenly throughout the pool, preventing localized high concentrations that could lead to increased wear. Regular backwashing of the filter and maintaining clean skimmer and pump baskets contribute to overall system efficiency.

Avoiding the use of certain pool chemicals that can interfere with salt chlorination systems is also important. For example, some algaecides containing metals can deposit on the anode surface, reducing its effectiveness. Sticking to products specifically designed for use with salt systems can help maintain anode performance.

Lastly, scheduling regular professional inspections of the entire salt chlorination system, including the anodes, can help identify and address potential issues before they lead to significant damage. Professional technicians can provide more thorough cleaning if necessary and offer advice on optimizing system performance based on the specific pool's characteristics and usage patterns.

By implementing these practices, pool owners can significantly extend the life of their titanium anodes, ensuring long-term efficiency and cost-effectiveness of their salt chlorination systems. While the exact lifespan can vary, with proper care and maintenance, many titanium anodes can last between 3 to 7 years or even longer, providing years of reliable service in keeping pool water clean and safe.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Lowry, R. W., & Dickman, J. E. (2015). Pool and Spa Operator Handbook. National Swimming Pool Foundation.

2. Wojtowicz, J. A. (2004). Cyanuric and isocyanuric acids. Kirk‐Othmer Encyclopedia of Chemical Technology.

3. Zhao, T., Gao, Y., & Zhang, Y. (2019). Research progress of electrode materials for electrochemical advanced oxidation processes in water treatment. Materials Research Express, 6(10), 102004.

4. Steininger, J., & Wright, K. R. (2011). Fifty meters: The long course. Meyer & Meyer Verlag.

5. Nalepa, C. J. (2004). Swimming pool water treatment. Kirk‐Othmer Encyclopedia of Chemical Technology.

6. World Health Organization. (2006). Guidelines for safe recreational water environments. Volume 2, Swimming pools and similar environments.

7. Zwiener, C., Richardson, S. D., De Marini, D. M., Grummt, T., Glauner, T., & Frimmel, F. H. (2007). Drowning in disinfection byproducts? Assessing swimming pool water. Environmental Science & Technology, 41(2), 363-372.

8. Canelli, E. (2013). Salt chlorination for pools. Journal of Environmental Health, 75(8), 42-44.

9. Wang, X., Lim, T. T., & Solt, Z. (2016). Electrochemical cell for swimming pool disinfection. Journal of Water Process Engineering, 11, 88-97.

10. Goodman, M., & Hind, J. (2019). The Complete Pool Manual for Homeowners and Professionals: A Step-by-Step Maintenance Guide. Atlantic Publishing Group Inc.

Related Industry Knowledge

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What Is a Chlorine Generator Electrolyzer and How Does It Operate?

- What is a DSA Anode and How Does It Work?

- What Industries Benefit from Chlorine Generator Electrolyzers for On-Site Production?

- What are DSA anodes?