- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Salt chlorination has revolutionized swimming pool maintenance, offering a more eco-friendly and cost-effective alternative to traditional chlorine-based systems. At the heart of this technology lies a crucial component: titanium electrodes. These electrodes play a pivotal role in the process of converting salt into chlorine, effectively sanitizing pool water. In this blog post, we'll delve into the fascinating world of titanium electrodes and explore their function in salt chlorination systems for swimming pools.

How does a salt chlorinator work to clean a pool?

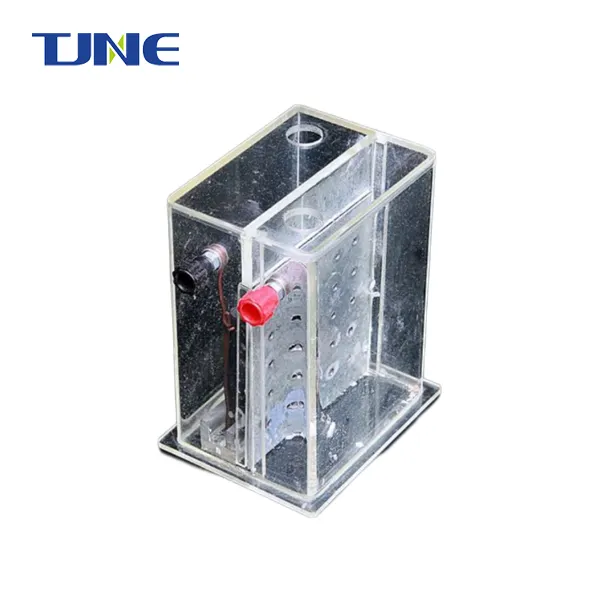

Salt chlorination is a process that utilizes electrolysis to generate chlorine from dissolved salt in pool water. The system consists of a control unit and a cell containing titanium electrodes. As saltwater passes through the cell, an electric current is applied to the titanium electrodes, triggering a chemical reaction that converts salt (sodium chloride) into chlorine gas.

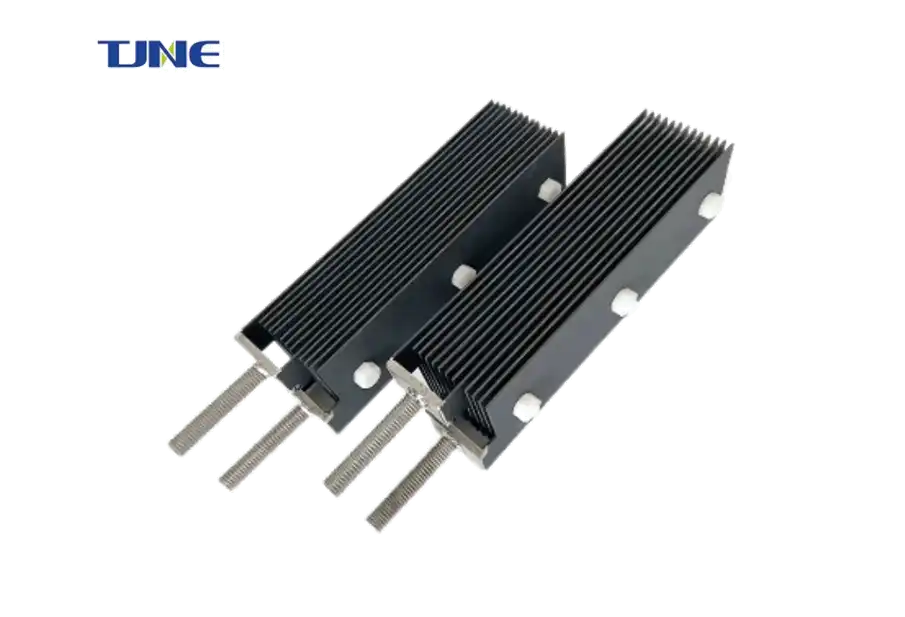

The process begins when pool water, containing a low concentration of salt (typically around 3,000 parts per million), enters the chlorinator cell. Inside the cell, titanium electrodes are arranged in a series of plates. These electrodes are coated with precious metals like ruthenium or iridium, which enhance their catalytic properties and longevity.

When an electric current is applied to the electrodes, it causes the sodium and chloride ions in the saltwater to separate. The negatively charged chloride ions are attracted to the positively charged anode, where they undergo oxidation. This reaction produces chlorine gas (Cl2), which immediately dissolves in the water to form hypochlorous acid (HOCl) – the same sanitizing agent used in traditional chlorine pools.

Meanwhile, at the negatively charged cathode, water molecules are split into hydrogen gas and hydroxide ions. The hydroxide ions combine with sodium ions to form sodium hydroxide, which helps balance the pool's pH levels.

The newly chlorinated water then returns to the pool, providing continuous sanitization. As the chlorine performs its disinfecting duties, it eventually reverts to salt, and the cycle begins anew. This closed-loop system ensures that the pool maintains proper chlorine levels with minimal intervention from the pool owner.

One of the key advantages of salt chlorination is its ability to produce a steady supply of chlorine, maintaining consistent sanitization levels. Traditional chlorine methods often result in fluctuating chlorine concentrations, which can lead to periods of under or over-chlorination. Salt systems, on the other hand, produce chlorine at a more constant rate, resulting in better water quality and a more comfortable swimming experience.

Moreover, salt chlorinators are equipped with controls that allow pool owners to adjust chlorine production based on factors such as pool size, bather load, and weather conditions. This flexibility ensures that the pool always has the right amount of chlorine to keep the water clean and safe.

It's worth noting that while salt chlorination systems are often marketed as "chlorine-free," they do, in fact, use chlorine as the primary sanitizing agent. The key difference is that the chlorine is generated on-site from salt, rather than being added directly to the pool in the form of chlorine tablets or liquid chlorine.

What are the benefits of using titanium electrodes in salt chlorinators?

Titanium electrodes are the unsung heroes of salt chlorination systems, offering a range of benefits that make them ideal for this application. Their unique properties contribute significantly to the efficiency, durability, and overall performance of salt chlorinators.

First and foremost, titanium's exceptional corrosion resistance is a crucial factor in its selection for use in salt chlorinators. Swimming pool environments are notoriously harsh, with high levels of chlorine, varying pH levels, and constant exposure to water. Titanium's natural ability to form a protective oxide layer on its surface makes it highly resistant to corrosion, even in these challenging conditions. This resistance ensures that the electrodes can withstand the constant exposure to saltwater and chlorine without degrading, leading to a longer lifespan for the chlorinator cell.

The durability of titanium electrodes translates directly into cost savings for pool owners. While the initial investment in a salt chlorination system might be higher than traditional chlorine methods, the longevity of titanium electrodes means less frequent replacements and lower maintenance costs over time. Many manufacturers offer warranties of 3-5 years on their chlorinator cells, with some high-quality units lasting even longer.

Another significant advantage of titanium electrodes is their excellent electrical conductivity. This property is essential for the efficient conversion of salt to chlorine through electrolysis. Titanium's conductivity allows for the smooth flow of electrical current through the electrodes, ensuring that the chlorination process occurs with minimal energy loss. As a result, salt chlorinators with titanium electrodes are often more energy-efficient than other alternatives, contributing to lower operating costs and a reduced environmental footprint.

The surface area of titanium electrodes also plays a crucial role in their effectiveness. Manufacturers often design the electrodes with specialized coatings and textures to maximize the surface area available for the electrolysis reaction. This increased surface area allows for more efficient chlorine production, even at lower salt concentrations. Consequently, pool owners can maintain proper sanitization levels while using less salt, further reducing the system's environmental impact and operating costs.

Titanium's lightweight nature is another benefit, particularly when it comes to the installation and maintenance of salt chlorination systems. The reduced weight of titanium electrodes compared to other materials makes the chlorinator cells easier to handle during installation and routine cleaning. This characteristic is especially appreciated by pool maintenance professionals who may need to service multiple systems in a day.

Furthermore, titanium electrodes are compatible with a wide range of pool chemistries. Whether a pool uses traditional chlorine, bromine, or alternative sanitizers in conjunction with the salt system, titanium electrodes can handle the varied chemical environments without compromising their performance or longevity. This versatility makes titanium-based salt chlorinators suitable for a diverse array of pool types and maintenance preferences.

It's also worth noting that titanium electrodes contribute to improved water quality and swimmer comfort. The consistent chlorine production facilitated by these electrodes helps maintain stable sanitization levels, reducing the occurrence of chlorine odors and eye irritation often associated with traditional chlorine pools. Many swimmers report that salt chlorinated pools feel softer on the skin and are less likely to cause the dryness or itchiness sometimes experienced in conventionally chlorinated pools.

Lastly, the use of titanium electrodes aligns with the growing trend towards more sustainable and eco-friendly pool maintenance practices. By enabling the efficient production of chlorine on-site, these electrodes help reduce the need for transportation and storage of chemical chlorine products. This not only decreases the carbon footprint associated with pool maintenance but also minimizes the risks of chemical spills or accidents during transport and handling.

How long do titanium electrodes last in salt chlorinators?

The longevity of titanium electrodes in salt chlorinators is a topic of great interest for pool owners considering this technology. While titanium itself is known for its durability, the lifespan of electrodes in a salt chlorination system can vary based on several factors. Understanding these factors and implementing proper maintenance practices can help pool owners maximize the life of their titanium electrodes and get the most value from their investment.

On average, titanium electrodes in salt chlorinators can last anywhere from 3 to 7 years, with some high-quality units lasting even longer under optimal conditions. This lifespan is significantly longer than that of other materials used in pool sanitization systems, making titanium electrodes a cost-effective choice in the long run.

The primary factor affecting the lifespan of titanium electrodes is the quality of their construction and coating. Most titanium electrodes used in salt chlorinators are coated with precious metals like ruthenium or iridium. These coatings enhance the electrodes' catalytic properties and protect the underlying titanium from degradation. Higher quality electrodes with more durable coatings tend to last longer, justifying their often higher initial cost.

Water chemistry plays a crucial role in determining electrode lifespan. Maintaining proper water balance is essential for preserving the integrity of the titanium electrodes. Imbalanced pH levels, particularly those that are too low (acidic), can accelerate the wear of the electrode coatings. Similarly, high levels of calcium hardness can lead to scale buildup on the electrodes, reducing their efficiency and potentially shortening their lifespan.

The salt concentration in the pool also affects electrode longevity. While salt chlorinators are designed to operate within a specific range of salt levels (typically 2700-3400 ppm), consistently maintaining the ideal concentration can help prolong electrode life. Too little salt can cause the system to work harder, potentially stressing the electrodes, while too much salt can lead to increased corrosion.

Usage patterns significantly impact electrode lifespan. Pools that require more frequent or intense chlorination due to high bather load, extreme weather conditions, or extended operating hours may experience faster electrode wear. Conversely, pools with lower chlorine demand and shorter operating seasons may see their electrodes last longer.

Proper maintenance is key to maximizing electrode life. Regular inspection and cleaning of the chlorinator cell can prevent the buildup of calcium scale and other deposits that can reduce efficiency and accelerate wear. Many manufacturers recommend cleaning the cell at least once per season, or more frequently if scale buildup is observed. Using appropriate cleaning methods and chemicals is crucial, as harsh cleaning agents or improper techniques can damage the electrode coatings.

The quality of the pool water itself can also affect electrode longevity. Water with high levels of metals, such as iron or copper, can contribute to electrode degradation over time. Using a metal sequestrant and maintaining proper water balance can help mitigate this issue.

Environmental factors, such as climate and weather patterns, play a role in electrode lifespan. Pools in areas with longer swimming seasons or hotter climates may require more chlorine production, potentially leading to faster electrode wear. Additionally, pools exposed to high levels of organic matter (e.g., leaves, pollen) may need to work harder to maintain proper sanitization, which can impact electrode life.

Advances in electrode technology continue to improve longevity. Some manufacturers now offer "reverse polarity" systems that periodically reverse the electrical current flow through the electrodes. This process can help prevent scale buildup and extend electrode life. Similarly, "smart" chlorination systems that adjust chlorine production based on real-time demand can help optimize electrode use and potentially extend their lifespan.

It's important for pool owners to be aware of signs indicating that their titanium electrodes may be nearing the end of their useful life. These signs can include a noticeable decrease in chlorine production, increased energy consumption by the chlorinator, or visible wear on the electrode plates. Many modern salt chlorination systems include self-diagnostic features that can alert owners to potential issues with the electrodes.

While the initial cost of a salt chlorination system with titanium electrodes may be higher than traditional chlorine methods, the long-term savings in chemical costs and reduced maintenance often offset this investment. Moreover, the improved water quality and reduced environmental impact associated with salt chlorination make it an attractive option for many pool owners.

In conclusion, titanium electrodes in salt chlorinators offer impressive longevity, typically lasting 3-7 years or more. By understanding the factors that affect electrode lifespan and implementing proper maintenance practices, pool owners can maximize the value of their salt chlorination systems. As technology continues to advance, we can expect to see further improvements in electrode durability and efficiency, making salt chlorination an even more attractive option for pool sanitation.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References

1. World Health Organization. (2006). Guidelines for safe recreational water environments. Volume 2, Swimming pools and similar environments.

2. Lowry, R. W., & Dickman, J. E. (2015). Pool and Spa Operator Handbook. National Swimming Pool Foundation.

3. Katz, B. M. (2006). U.S. Patent No. 7,014,768. Washington, DC: U.S. Patent and Trademark Office.

4. Macka, M., Andersson, P., & Haddad, P. R. (1998). Linearity evaluation in absorbance detection: The use of light-emitting diodes for on-capillary detection in capillary electrophoresis. Electrophoresis, 19(16-17), 2815-2820.

5. Judd, S. J., & Black, S. H. (2000). Disinfection by-product formation in swimming pool waters: a simple mass balance. Water Research, 34(5), 1611-1619.

6. Zwiener, C., Richardson, S. D., De Marini, D. M., Grummt, T., Glauner, T., & Frimmel, F. H. (2007). Drowning in disinfection byproducts? Assessing swimming pool water. Environmental Science & Technology, 41(2), 363-372.

7. Beech, J. A., Diaz, R., Ordaz, C., & Palomeque, B. (1980). Nitrates, chlorates and trihalomethanes in swimming pool water. American Journal of Public Health, 70(1), 79-82.

8. Kristensen, G. H., Klausen, M. M., & Janning, K. (2007). Experimental operation of a small full-scale swimming pool to evaluate the efficiency of different water treatment technologies. In Swimming Pool & Spa International Conference, Munich, Germany.

9. Keuten, M. G. A., Schets, F. M., Schijven, J. F., Verberk, J. Q. J. C., & van Dijk, J. C. (2012). Definition and quantification of initial anthropogenic pollutant release in swimming pools. Water Research, 46(11), 3682-3692.

10. Weng, S., & Blatchley III, E. R. (2011). Disinfection by-product dynamics in a chlorinated, indoor swimming pool under conditions of heavy use: National swimming competition. Water Research, 45(16), 5241-5248.

Related Industry Knowledge

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- What Industries Rely on DSA Anodes for Electrochemical Processes?

- What Factors Should Be Considered When Selecting a DSA Anode?

- What Is a Chlorine Generator Electrolyzer and How Does It Operate?

- What is a DSA Anode and How Does It Work?

- What Industries Benefit from Chlorine Generator Electrolyzers for On-Site Production?