- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

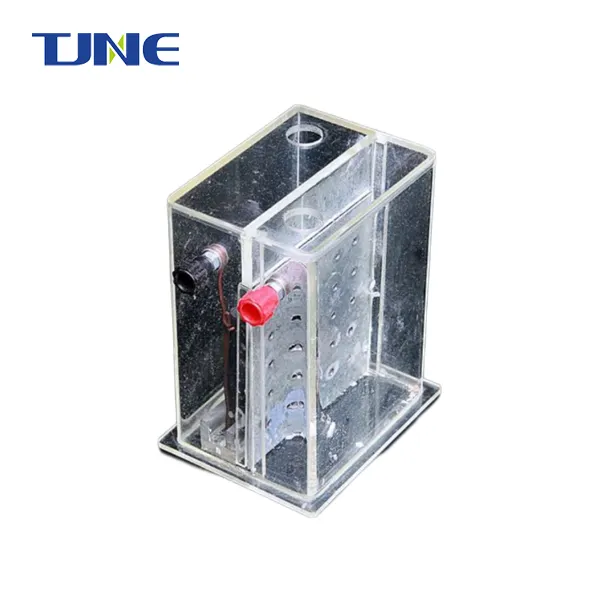

Titanium electrodes have garnered significant attention in the water treatment industry due to their exceptional properties and potential applications. As municipalities and industries seek more efficient and sustainable methods for water purification, the use of titanium electrodes in large-scale water treatment plants has become a topic of great interest. These electrodes offer several advantages, including corrosion resistance, durability, and high conductivity, making them potentially suitable for various water treatment processes. In this blog post, we will explore the feasibility and benefits of using titanium electrodes in large-scale water treatment facilities, addressing some of the most commonly asked questions about this technology.

How do titanium electrodes compare to traditional materials in water treatment?

Titanium electrodes have emerged as a promising alternative to traditional materials used in water treatment processes, offering several distinct advantages. When compared to conventional electrode materials such as stainless steel, graphite, or lead, titanium electrodes demonstrate superior performance in many aspects.

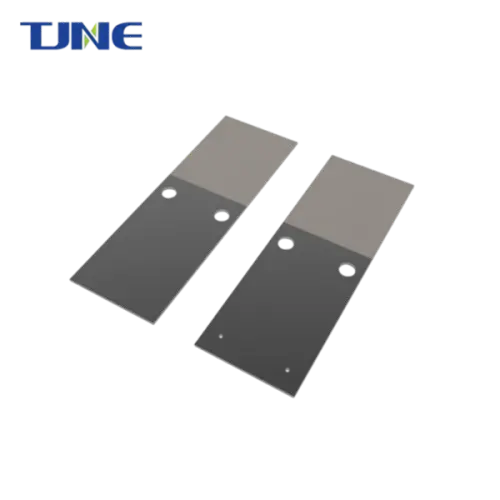

One of the primary benefits of titanium electrodes is their exceptional corrosion resistance. Unlike many other metals, titanium forms a stable oxide layer on its surface when exposed to air or water, providing natural protection against corrosion. This property is particularly valuable in water treatment applications, where electrodes are constantly exposed to various chemicals and contaminants. The corrosion resistance of titanium electrodes translates to longer service life and reduced maintenance requirements, making them a cost-effective choice for large-scale water treatment plants.

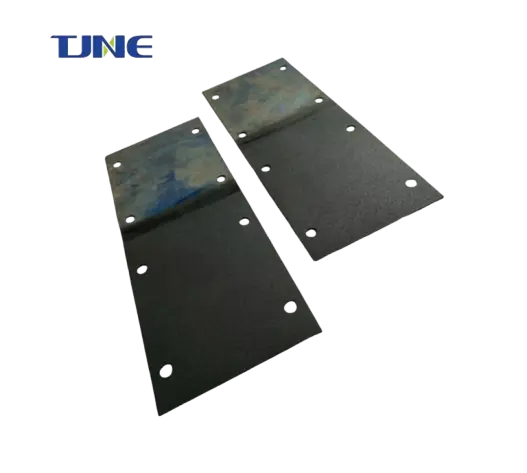

Another significant advantage of titanium electrodes is their high conductivity. While pure titanium itself is not an excellent conductor, titanium electrodes used in water treatment are typically coated with conductive materials such as platinum, iridium oxide, or ruthenium oxide. These coatings enhance the electrochemical properties of the electrodes, allowing for efficient electron transfer and improved performance in electrochemical processes. The combination of a corrosion-resistant titanium substrate with a highly conductive coating results in electrodes that can maintain their effectiveness over extended periods, even in challenging water treatment environments.

Titanium electrodes also offer excellent mechanical strength and durability. They can withstand high temperatures and pressures, making them suitable for a wide range of water treatment applications. This robustness ensures that the electrodes can maintain their structural integrity and performance even under demanding operating conditions, reducing the risk of failure and the need for frequent replacements.

Furthermore, titanium electrodes have a lower environmental impact compared to some traditional electrode materials. For instance, lead electrodes, which have been used in certain water treatment applications, pose environmental and health risks due to the potential release of lead ions. Titanium electrodes, on the other hand, are non-toxic and do not leach harmful substances into the water, making them a more environmentally friendly option.

In terms of versatility, titanium electrodes can be used in various water treatment processes, including electrocoagulation, electrooxidation, and electrochlorination. Their ability to perform effectively in different applications makes them a flexible choice for water treatment plant designers and operators, potentially simplifying equipment selection and maintenance procedures.

However, it is important to note that the initial cost of titanium electrodes is generally higher than that of traditional materials. This higher upfront investment can be a barrier to adoption for some water treatment facilities. Nevertheless, when considering the total cost of ownership, including factors such as longevity, reduced maintenance requirements, and improved performance, titanium electrodes often prove to be a cost-effective solution in the long run.

In conclusion, titanium electrodes offer several significant advantages over traditional materials in water treatment applications. Their corrosion resistance, high conductivity (when properly coated), durability, environmental friendliness, and versatility make them an attractive option for large-scale water treatment plants. While the initial cost may be higher, the long-term benefits and performance improvements can justify the investment, particularly for facilities seeking to enhance their treatment efficiency and reduce operational costs.

What are the challenges of implementing titanium electrodes in large-scale water treatment plants?

While titanium electrodes offer numerous benefits for water treatment applications, implementing them in large-scale water treatment plants comes with its own set of challenges. Understanding these challenges is crucial for water treatment plant operators and designers considering the adoption of this technology.

One of the primary challenges is the high initial cost of titanium electrodes. Titanium is a relatively expensive metal compared to traditional electrode materials like steel or graphite. Additionally, the specialized coatings required to enhance the electrochemical properties of titanium electrodes, such as platinum or iridium oxide, further increase the upfront investment. This higher initial cost can be a significant barrier for many water treatment facilities, especially those operating under tight budget constraints. However, it's important to consider that the long-term benefits, including reduced maintenance and replacement costs, may offset this initial expense over time.

Another challenge lies in the design and engineering aspects of integrating titanium electrodes into existing water treatment systems. Many large-scale water treatment plants have been designed and optimized for use with traditional electrode materials. Retrofitting these systems to accommodate titanium electrodes may require significant modifications to the plant's infrastructure, electrical systems, and control mechanisms. This process can be complex, time-consuming, and potentially disruptive to the plant's operations. Careful planning and engineering are necessary to ensure a smooth transition and to maximize the benefits of the new electrode technology.

The optimization of operating parameters presents another challenge when implementing titanium electrodes. Different water treatment processes and water qualities may require specific electrode configurations, current densities, and other operational parameters to achieve optimal performance. Determining these optimal conditions can involve extensive testing and fine-tuning, which may require specialized expertise and resources. Furthermore, as water quality and treatment requirements can vary seasonally or due to changes in source water, ongoing optimization and adjustment of the electrode system may be necessary.

Maintenance and monitoring of titanium electrodes also present unique challenges. While these electrodes are known for their durability and corrosion resistance, they still require regular inspection and maintenance to ensure optimal performance. The specialized coatings on titanium electrodes can degrade over time, particularly under harsh operating conditions. Monitoring the condition of these coatings and determining when replacement or recoating is necessary can be more complex than with traditional electrode materials. Additionally, the high cost of titanium electrodes makes proper maintenance crucial to protect the investment and maximize the electrodes' lifespan.

Training and familiarization of plant operators and maintenance staff with titanium electrode technology is another important consideration. The unique properties and maintenance requirements of titanium electrodes may necessitate additional training programs to ensure that staff can effectively operate and maintain the new system. This may include education on the electrochemical principles involved, safety considerations, and specific maintenance procedures.

Regulatory compliance and approval can also pose challenges when implementing titanium electrodes in large-scale water treatment plants. Depending on the jurisdiction, there may be specific regulations or approval processes required for the use of new technologies in drinking water treatment. Demonstrating the safety and efficacy of titanium electrodes to regulatory bodies may require extensive testing and documentation, which can be time-consuming and costly.

Lastly, the long-term performance and reliability of titanium electrodes in large-scale water treatment applications are still being studied. While laboratory studies and smaller-scale implementations have shown promising results, there is limited long-term data on the performance of these electrodes in full-scale municipal water treatment plants. This lack of extensive long-term data may create uncertainty for decision-makers considering the adoption of this technology.

In conclusion, while titanium electrodes offer significant potential benefits for large-scale water treatment plants, their implementation comes with several challenges. These include high initial costs, design and engineering considerations, optimization of operating parameters, maintenance and monitoring requirements, staff training needs, regulatory compliance, and the need for more long-term performance data. Addressing these challenges requires careful planning, investment in research and development, and collaboration between water treatment plant operators, engineers, and technology providers. As the technology continues to mature and more large-scale implementations are realized, many of these challenges may be mitigated, paving the way for wider adoption of titanium electrodes in water treatment applications.

How effective are titanium electrodes in removing contaminants from drinking water?

The effectiveness of titanium electrodes in removing contaminants from drinking water is a critical consideration for water treatment professionals and researchers. Titanium electrodes, particularly when coated with appropriate materials, have shown promising results in various water treatment processes aimed at contaminant removal. Their effectiveness can vary depending on the specific contaminants present, the treatment process employed, and the overall water quality parameters.

One of the primary applications of titanium electrodes in drinking water treatment is in electrochemical oxidation processes. In these processes, titanium electrodes coated with materials such as mixed metal oxides (MMO) are used to generate powerful oxidizing agents directly in the water. These oxidizing agents, such as hydroxyl radicals, ozone, and chlorine species, can effectively degrade a wide range of organic contaminants, including persistent organic pollutants, pharmaceuticals, and personal care products.

Research has shown that electrochemical oxidation using titanium-based electrodes can be highly effective in removing various organic contaminants. For example, studies have demonstrated removal efficiencies of over 90% for certain pharmaceuticals and endocrine-disrupting compounds. The process is particularly effective against recalcitrant organic pollutants that are resistant to conventional treatment methods. Moreover, the ability to generate oxidizing agents in-situ eliminates the need for chemical addition, potentially simplifying the treatment process and reducing operational costs.

The effectiveness of titanium electrodes in removing inorganic contaminants, particularly heavy metals, has also been demonstrated in various studies. Electrochemical processes using titanium electrodes can facilitate the removal of metals such as arsenic, lead, and chromium through mechanisms including oxidation, reduction, and electrodeposition. For instance, research has shown that electrochemical treatment using titanium electrodes can achieve arsenic removal efficiencies of over 95% under optimized conditions.

Titanium electrodes have also proven effective in disinfection processes, particularly in electrochlorination applications. When used as anodes in the electrolysis of chloride-containing water, titanium electrodes can generate chlorine species that provide powerful disinfection capabilities. This process is particularly useful in treating water with high chloride content, such as seawater or brackish water, for potable use. The on-site generation of disinfectants using titanium electrodes can offer advantages in terms of safety and cost-effectiveness compared to traditional chlorination methods.

Another area where titanium electrodes have shown promise is in the removal of emerging contaminants, such as per- and polyfluoroalkyl substances (PFAS). These persistent environmental pollutants have become a significant concern in drinking water sources. Recent studies have explored the use of electrochemical treatment with titanium-based electrodes for PFAS removal, with some showing promising results in degrading these challenging compounds.

It's important to note that the effectiveness of titanium electrodes in contaminant removal can be influenced by various factors, including water quality parameters (pH, conductivity, temperature), the presence of competing ions or organic matter, and the specific electrode configuration and operating conditions. Optimizing these parameters is crucial to achieving maximum contaminant removal efficiency.

Moreover, the long-term performance and stability of titanium electrodes in full-scale drinking water treatment applications are still being evaluated. While laboratory and pilot-scale studies have demonstrated high effectiveness, the performance of these electrodes over extended periods in real-world treatment plants may vary. Factors such as electrode fouling, coating degradation, and changes in water quality can impact long-term effectiveness and require ongoing monitoring and maintenance.

In conclusion, titanium electrodes have demonstrated significant effectiveness in removing a wide range of contaminants from drinking water, including organic pollutants, heavy metals, and pathogens. Their versatility in various electrochemical treatment processes, combined with their durability and corrosion resistance, makes them a promising technology for advanced water treatment. However, the effectiveness can vary depending on specific contaminants and water quality conditions, and optimizing treatment parameters is crucial for achieving maximum removal efficiencies. As research continues and more full-scale implementations are realized, the effectiveness of titanium electrodes in drinking water treatment is likely to be further validated and improved, potentially leading to wider adoption in large-scale water treatment plants.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Chen, G. (2004). Electrochemical technologies in wastewater treatment. Separation and Purification Technology, 38(1), 11-41.

2. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

3. Radjenovic, J., & Sedlak, D. L. (2015). Challenges and opportunities for electrochemical processes as next-generation technologies for the treatment of contaminated water. Environmental Science & Technology, 49(19), 11292-11302.

4. Särkkä, H., Bhatnagar, A., & Sillanpää, M. (2015). Recent developments of electro-oxidation in water treatment—A review. Journal of Electroanalytical Chemistry, 754, 46-56.

5. Garcia-Segura, S., Ocon, J. D., & Chong, M. N. (2018). Electrochemical oxidation remediation of real wastewater effluents—A review. Process Safety and Environmental Protection, 113, 48-67.

6. Moreira, F. C., Boaventura, R. A., Brillas, E., & Vilar, V. J. (2017). Electrochemical advanced oxidation processes: A review on their application to synthetic and real wastewaters. Applied Catalysis B: Environmental, 202, 217-261.

7. Chaplin, B. P. (2014). Critical review of electrochemical advanced oxidation processes for water treatment applications. Environmental Science: Processes & Impacts, 16(6), 1182-1203.

8. Feng, Y., Yang, L., Liu, J., & Logan, B. E. (2016). Electrochemical technologies for wastewater treatment and resource reclamation. Environmental Science: Water Research & Technology, 2(5), 800-831.

9. Sirés, I., Brillas, E., Oturan, M. A., Rodrigo, M. A., & Panizza, M. (2014). Electrochemical advanced oxidation processes: today and tomorrow. A review. Environmental Science and Pollution Research, 21(14), 8336-8367.

10. Ganiyu, S. O., Martínez-Huitle, C. A., & Rodrigo, M. A. (2020). Renewable energies driven electrochemical wastewater/soil decontamination technologies: A critical review of fundamental concepts and applications. Applied Catalysis B: Environmental, 270, 118857.

Related Industry Knowledge

- What does a Ballast Water Titanium Electrode do?

- How Do Anodes Facilitate the Removal of Ammonia Nitrogen from Water?

- Unlocking the Potential: The Science and Applications of Acidic Electrolytic Water

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Crystal Clear Waters: The Power of Titanium Electrodes in Pool Disinfection

- The Power of Splitting Water: An In-Depth Look at Alkaline Water Electrolyzers

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- Purifying the Seas: The Role of Titanium Electrodes in Ballast Water Treatment