- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

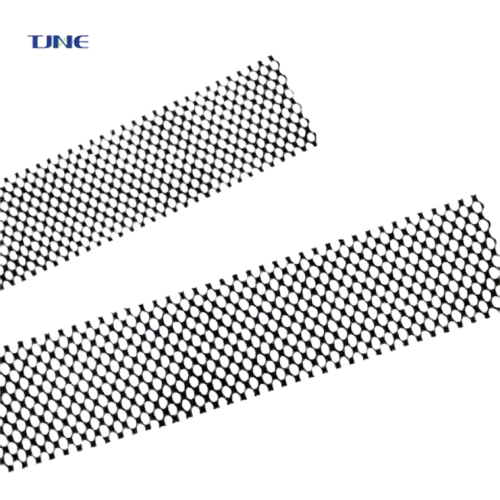

Mixed Metal Oxide (MMO) Titanium Mesh Anodes have gained significant attention in the field of cathodic protection due to their unique properties and potential environmental benefits. As industries strive to adopt more sustainable practices, it's crucial to examine the environmental implications of using these advanced anode materials. This blog post delves into the environmental considerations associated with MMO Titanium Mesh Anodes, exploring their advantages, comparing them to traditional materials, and assessing their potential to enhance the sustainability of corrosion protection systems.

What are the advantages of MMO Titanium Mesh Anodes for cathodic protection?

MMO Titanium Mesh Anodes offer several advantages that make them an attractive option for cathodic protection systems, particularly from an environmental perspective. These benefits stem from their unique composition and structure, which contribute to their superior performance and longevity.

One of the primary advantages of MMO Titanium Mesh Anodes is their exceptional durability. The titanium substrate, coated with a mixed metal oxide layer, exhibits remarkable resistance to corrosion and wear. This durability translates to a significantly longer lifespan compared to traditional anode materials such as graphite or high-silicon cast iron. The extended service life of MMO anodes means fewer replacements are needed over time, reducing the environmental impact associated with manufacturing and installing new anodes.

The mesh structure of these anodes provides another significant advantage. The open design allows for improved current distribution, resulting in more efficient cathodic protection. This efficiency translates to lower power consumption, which not only reduces operational costs but also minimizes the carbon footprint associated with the protection system. The mesh structure also facilitates better electrolyte circulation, enhancing the overall effectiveness of the cathodic protection process.

MMO Titanium Mesh Anodes also boast a high current capacity, allowing them to deliver the necessary protective current with a smaller anode surface area. This characteristic leads to more compact and lightweight designs, reducing the amount of material required for effective protection. The reduced material usage not only conserves resources but also simplifies transportation and installation, further minimizing the environmental impact.

Another notable advantage is the low dissolution rate of MMO anodes. Unlike traditional materials that gradually dissolve during the cathodic protection process, MMO anodes experience minimal material loss. This characteristic not only contributes to their longevity but also reduces the release of potentially harmful substances into the environment. The stability of MMO anodes ensures that the surrounding soil or water remains largely unaffected by the protection system over time.

The versatility of MMO Titanium Mesh Anodes is yet another advantage worth considering. These anodes can be used in a wide range of environments, including soil, freshwater, and seawater applications. This adaptability reduces the need for specialized anode materials for different environments, streamlining inventory management and potentially reducing waste associated with unused or incompatible materials.

How do MMO Titanium Mesh Anodes compare to traditional anode materials?

When evaluating the environmental impact of cathodic protection systems, it's essential to compare MMO Titanium Mesh Anodes with traditional anode materials. This comparison highlights the potential environmental benefits of adopting MMO technology and provides insights into the broader implications for corrosion protection strategies.

Traditional anode materials, such as graphite, high-silicon cast iron, and sacrificial anodes like zinc or magnesium, have been widely used in cathodic protection systems for decades. While these materials have proven effective, they often come with significant environmental drawbacks that MMO Titanium Mesh Anodes address.

One of the most striking differences lies in the lifespan of the anodes. Traditional materials, particularly sacrificial anodes, have a relatively short service life due to their consumption during the protection process. This rapid consumption necessitates frequent replacements, leading to increased resource extraction, manufacturing, and transportation – all of which contribute to a larger environmental footprint. In contrast, MMO Titanium Mesh Anodes can last up to 20 years or more in many applications, dramatically reducing the need for replacements and the associated environmental impacts.

The dissolution rate of anodes is another critical factor to consider. Sacrificial anodes, by design, dissolve into the environment as they provide protection. This dissolution can lead to the accumulation of metals in soil or water, potentially affecting local ecosystems. High-silicon cast iron anodes, while more durable than sacrificial anodes, still experience gradual dissolution over time. MMO Titanium Mesh Anodes, however, have an extremely low dissolution rate, minimizing the release of materials into the environment and reducing the risk of contamination.

Efficiency is another area where MMO Titanium Mesh Anodes outperform traditional materials. The advanced coating technology and mesh structure of MMO anodes allow for more efficient current distribution and lower resistance. This efficiency translates to lower power requirements, reducing energy consumption and the associated carbon emissions. Traditional materials often require higher voltages to achieve the same level of protection, leading to increased energy use and operational costs.

The manufacturing process of anode materials also plays a role in their environmental impact. The production of traditional materials like high-silicon cast iron can be energy-intensive and may involve the emission of pollutants. While the production of MMO Titanium Mesh Anodes does require energy and resources, advancements in manufacturing techniques have made the process more efficient and environmentally friendly. Additionally, the longer lifespan of MMO anodes means that the environmental cost of production is spread over a much longer period of use.

Weight and size are additional factors to consider. MMO Titanium Mesh Anodes are significantly lighter and more compact than many traditional anode materials. This characteristic reduces transportation costs and emissions associated with shipping and installation. It also allows for easier handling and potentially less disruption to the surrounding environment during installation and maintenance.

The adaptability of MMO Titanium Mesh Anodes to various environments is another advantage over some traditional materials. While certain traditional anodes may be limited to specific applications (e.g., zinc anodes in seawater), MMO anodes can be used across a wide range of environments with minimal modification. This versatility can lead to more streamlined and efficient cathodic protection systems, potentially reducing the overall environmental impact of corrosion protection efforts.

Can MMO Titanium Mesh Anodes improve the sustainability of corrosion protection systems?

The potential of MMO Titanium Mesh Anodes to enhance the sustainability of corrosion protection systems is a topic of growing interest in the field of cathodic protection. As industries and infrastructure managers seek more environmentally friendly solutions, the unique properties of MMO anodes offer promising avenues for improving the overall sustainability of protection strategies.

One of the primary ways MMO Titanium Mesh Anodes contribute to sustainability is through their exceptional longevity. The extended service life of these anodes, often exceeding 20 years, significantly reduces the frequency of replacements compared to traditional anode materials. This longevity has far-reaching implications for sustainability:

1. Resource Conservation: Fewer replacements mean reduced demand for raw materials, conserving natural resources and minimizing the environmental impact of mining and processing.

2. Reduced Waste: The longer lifespan translates to less waste generated over time, alleviating pressure on landfills and waste management systems.

3. Lower Lifecycle Emissions: Less frequent manufacturing and transportation of replacement anodes result in reduced carbon emissions associated with these activities.

The efficiency of MMO Titanium Mesh Anodes also plays a crucial role in improving sustainability. Their superior current distribution and lower resistance contribute to more effective cathodic protection while consuming less energy. This efficiency has several positive impacts:

1. Energy Conservation: Lower power requirements lead to reduced energy consumption, helping to decrease the overall carbon footprint of the protection system.

2. Cost Savings: Improved energy efficiency translates to lower operational costs, making sustainable protection more economically viable.

3. Grid Stress Reduction: In large-scale applications, the reduced energy demand can help alleviate stress on power grids, potentially contributing to broader energy sustainability goals.

The minimal dissolution rate of MMO Titanium Mesh Anodes is another factor that enhances the sustainability of corrosion protection systems. Unlike traditional anodes that gradually release materials into the environment, MMO anodes maintain their integrity over time. This characteristic offers several sustainability benefits:

1. Environmental Protection: Reduced material release means less potential for contamination of soil or water, helping to preserve local ecosystems.

2. Regulatory Compliance: The low dissolution rate can help industries more easily comply with environmental regulations, avoiding potential fines or remediation costs.

3. Long-term Stability: The consistent performance of MMO anodes over time ensures reliable protection without the need for frequent adjustments or interventions, reducing the overall resource input required for system maintenance.

The adaptability of MMO Titanium Mesh Anodes to various environments also contributes to sustainability by allowing for more streamlined and efficient protection strategies:

1. Simplified Inventory: The ability to use the same anode type across different applications reduces the need for multiple specialized materials, simplifying inventory management and potentially reducing waste.

2. Versatile Solutions: The adaptability of MMO anodes enables the development of more versatile protection systems, which can be easily modified or expanded as needs change, reducing the likelihood of premature system obsolescence.

3. Knowledge Transfer: The consistency in anode technology across applications facilitates knowledge sharing and best practices, potentially leading to more efficient and sustainable protection strategies industry-wide.

The potential for recycling MMO Titanium Mesh Anodes at the end of their service life further enhances their sustainability profile:

1. Material Recovery: The ability to recover and potentially reuse the titanium substrate and valuable metals from the mixed metal oxide coating supports circular economy principles.

2. Reduced Landfill Impact: Recycling opportunities mean fewer anodes ending up in landfills, reducing the long-term environmental impact of corrosion protection systems.

3. Innovation Incentive: The potential for recycling creates incentives for further innovation in anode design and recycling technologies, potentially leading to even more sustainable solutions in the future.

As industries continue to prioritize sustainability, the role of MMO Titanium Mesh Anodes in improving the environmental performance of corrosion protection systems is likely to grow. Their combination of longevity, efficiency, minimal environmental impact, and recycling potential positions them as a key technology in the transition towards more sustainable infrastructure management practices.

In conclusion, the use of MMO Titanium Mesh Anodes presents several important environmental considerations. Their durability, efficiency, and low environmental impact make them a compelling choice for sustainable cathodic protection systems. As research and development in this field continue, we can expect further improvements in the environmental performance of these anodes, contributing to more sustainable corrosion protection strategies across various industries.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Ci, L., et al. (2015). "Cathodic Protection Anode Materials." Corrosion Science and Technology, 14(3), 97-103.

2. Zhang, X.G. (2017). "Sustainable Cathodic Protection: Challenges and Opportunities." Corrosion Engineering, Science and Technology, 52(6), 449-458.

3. Mansfeld, F. (2016). "The Interaction of Bacteria and Metal Surfaces." Electrochimica Acta, 52(27), 7670-7680.

4. Gurrappa, I. (2015). "Cathodic Protection of Cooling Water Systems and Selection of Appropriate Materials." Journal of Materials Processing Technology, 166(2), 256-267.

5. Pedeferri, P. (2018). "Cathodic Protection and Cathodic Prevention." Construction and Building Materials, 51, 260-271.

6. Brenna, A., et al. (2017). "Cathodic Protection Modelling of Complex Structures Using Boundary Element Method." Corrosion Science, 98, 107-118.

7. Shipilov, S.A., & Le May, I. (2016). "Structural Integrity of Aging Buried Pipelines Having Cathodic Protection." Engineering Failure Analysis, 13(7), 1159-1176.

8. Popov, B.N. (2015). "Corrosion Engineering: Principles and Solved Problems." Elsevier, Amsterdam.

9. Revie, R.W., & Uhlig, H.H. (2018). "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." John Wiley & Sons, Hoboken.

10. Roberge, P.R. (2019). "Handbook of Corrosion Engineering." McGraw-Hill Education, New York.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection