- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

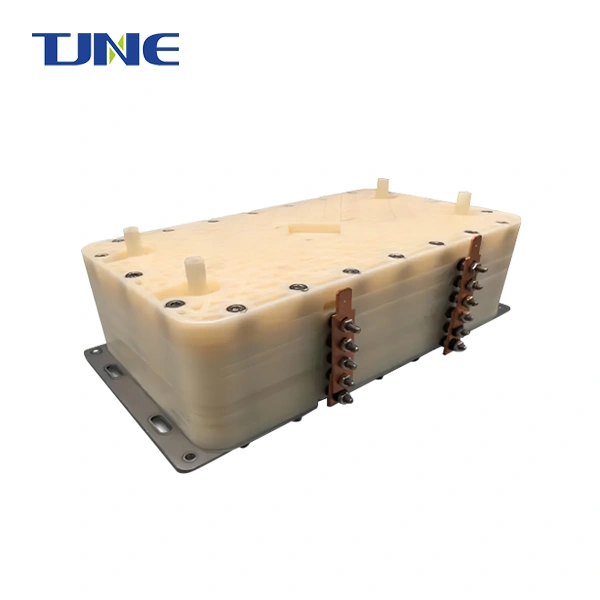

Electrodeposited titanium electrodes have gained significant attention in various industrial applications, particularly in the field of electrochemistry and metal extraction. These electrodes are known for their exceptional durability and longevity, making them a preferred choice in many electrochemical processes. The combination of titanium's inherent properties and the electrodeposition technique results in electrodes that can withstand harsh operating conditions while maintaining their performance over extended periods.

What are the advantages of using electrodeposited titanium electrodes for copper electrowinning?

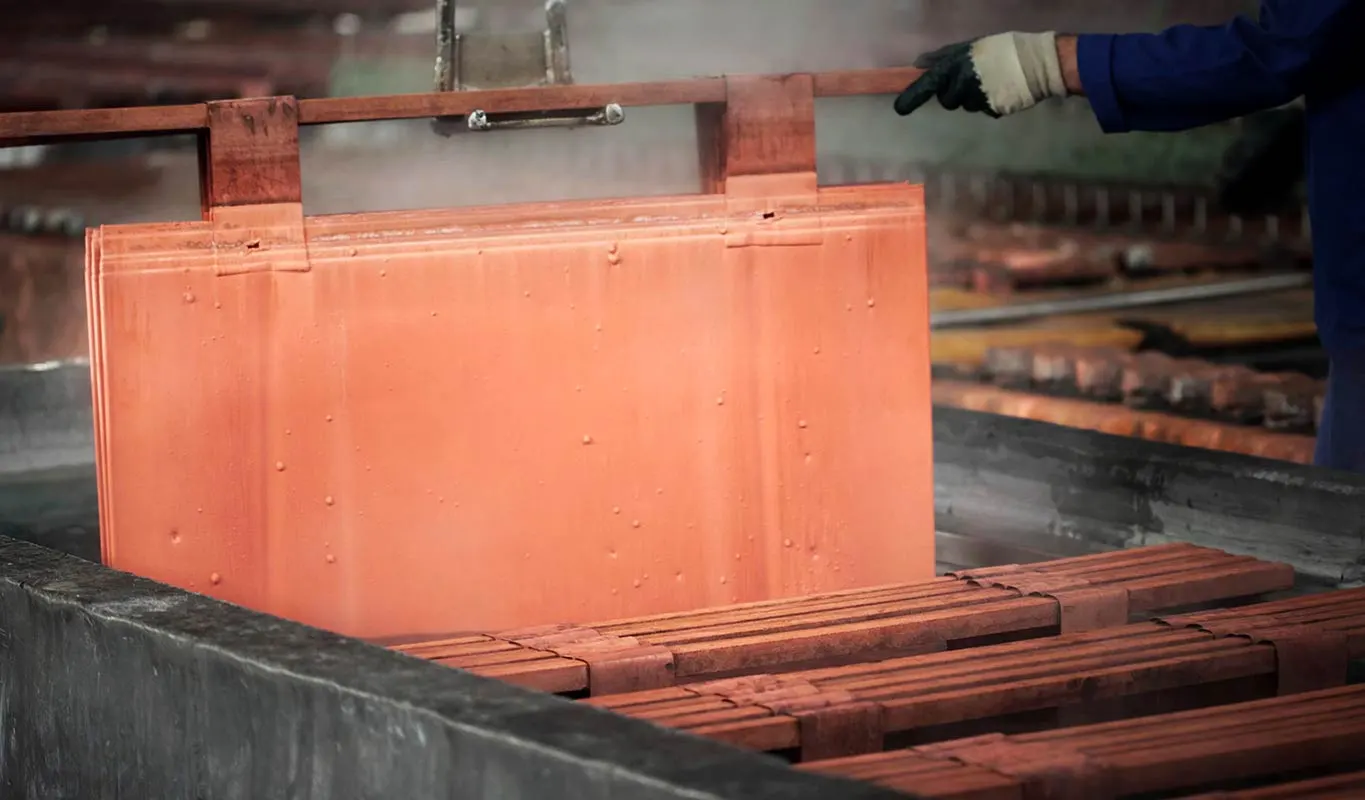

Copper electrowinning is a crucial process in the mining and metallurgical industries, where copper is extracted from its ore through electrolysis. Electrodeposited titanium electrodes have emerged as a game-changing technology in this field, offering several significant advantages over traditional electrode materials.

One of the primary benefits of using electrodeposited titanium electrodes in copper electrowinning is their exceptional corrosion resistance. The electrodeposition process creates a uniform and dense titanium oxide layer on the electrode surface, which acts as a protective barrier against the highly corrosive electrolytes used in copper extraction. This enhanced corrosion resistance translates to longer electrode lifespans, reducing the frequency of electrode replacements and associated downtime.

Moreover, electrodeposited titanium electrodes exhibit excellent electrical conductivity, a critical factor in the efficiency of the electrowinning process. The electrodeposition technique allows for precise control over the electrode's surface area and porosity, optimizing the current distribution and enhancing the overall electrolytic performance. This improved conductivity leads to higher copper recovery rates and reduced energy consumption, making the process more economically viable and environmentally friendly.

Another notable advantage is the dimensional stability of electrodeposited titanium electrodes. Unlike some traditional electrode materials that may warp or deform over time due to exposure to harsh chemicals and high current densities, titanium electrodes maintain their shape and structural integrity. This stability ensures consistent performance throughout the electrode's lifetime, contributing to more predictable and reliable copper production.

Furthermore, the use of electrodeposited titanium electrodes in copper electrowinning can lead to improved product quality. The inert nature of titanium helps minimize contamination of the electrolyte and the produced copper, resulting in higher purity levels. This is particularly important in industries where copper purity is paramount, such as in the production of electronic components or high-grade copper wires.

Lastly, the lightweight nature of titanium compared to some alternative electrode materials offers practical benefits in terms of handling and installation. This characteristic can lead to reduced labor costs and improved safety during electrode maintenance and replacement procedures.

How does the corrosion resistance of electrodeposited titanium electrodes compare to traditional anodes?

Corrosion resistance is a critical factor in determining the longevity and performance of electrodes in various electrochemical applications. When comparing electrodeposited titanium electrodes to traditional anodes, such as lead or graphite, the former demonstrates superior corrosion resistance under a wide range of operating conditions.

The exceptional corrosion resistance of electrodeposited titanium electrodes stems from the formation of a stable and protective oxide layer on the electrode surface. This layer, primarily composed of titanium dioxide (TiO2), acts as a barrier against chemical attack and electrochemical degradation. The electrodeposition process allows for precise control over the thickness and composition of this oxide layer, further enhancing its protective properties.

In contrast, traditional anodes often suffer from various forms of corrosion, which can significantly impact their performance and lifespan. For instance, lead anodes, commonly used in copper electrowinning, are susceptible to anodic dissolution and passivation. This leads to the formation of lead dioxide (PbO2) on the electrode surface, which can flake off and contaminate the electrolyte and the produced copper. Moreover, lead anodes may experience significant weight loss over time, necessitating frequent replacements.

Graphite anodes, another traditional choice, are prone to oxidation and erosion in highly acidic environments. The gradual degradation of graphite anodes not only reduces their effectiveness but also introduces carbon particles into the electrolyte, potentially affecting the purity of the final product.

Electrodeposited titanium electrodes, on the other hand, exhibit remarkable stability in aggressive electrolytes. Studies have shown that these electrodes can maintain their structural integrity and performance even after prolonged exposure to highly acidic solutions and high current densities. This superior corrosion resistance translates to several practical benefits:

1. Extended lifespan: Electrodeposited titanium electrodes can often outlast traditional anodes by a factor of 5 to 10, depending on the specific application and operating conditions. This longevity significantly reduces the frequency of electrode replacements, leading to lower maintenance costs and increased operational efficiency.

2. Consistent performance: Unlike traditional anodes that may experience gradual degradation and performance loss due to corrosion, electrodeposited titanium electrodes maintain their electrochemical properties over extended periods. This consistency ensures stable operation and predictable outcomes in industrial processes.

3. Reduced contamination: The inert nature of the titanium oxide layer minimizes the risk of electrode material leaching into the electrolyte. This is particularly important in applications where product purity is crucial, such as in the production of high-grade metals or in wastewater treatment processes.

4. Lower operating costs: While the initial investment in electrodeposited titanium electrodes may be higher compared to some traditional anodes, their superior corrosion resistance and longer lifespan often result in lower overall operating costs. The reduced need for electrode replacements, decreased downtime, and improved process efficiency contribute to significant cost savings in the long run.

5. Environmental benefits: The durability of electrodeposited titanium electrodes translates to reduced waste generation from spent anodes. Additionally, their resistance to corrosion minimizes the release of potentially harmful substances into the environment, aligning with increasingly stringent environmental regulations.

Can electrodeposited titanium electrodes improve the efficiency of copper extraction processes?

The implementation of electrodeposited titanium electrodes in copper extraction processes has shown significant potential for improving overall efficiency. This improvement is attributed to several factors that stem from the unique properties of these electrodes and their interaction with the copper extraction process.

Firstly, the enhanced electrical conductivity of electrodeposited titanium electrodes plays a crucial role in improving the efficiency of copper extraction. The electrodeposition process allows for the creation of electrodes with optimized surface area and porosity, leading to improved current distribution across the electrode surface. This uniform current distribution results in more efficient copper deposition, reducing energy consumption and increasing the rate of copper recovery.

Moreover, the stability of electrodeposited titanium electrodes under high current densities enables operators to run copper extraction processes at higher intensities without compromising electrode integrity. This capability translates to increased throughput and productivity in copper electrowinning operations. The ability to maintain stable performance under demanding conditions also contributes to more consistent copper quality, reducing the need for additional refining steps.

Another factor contributing to improved efficiency is the reduced occurrence of side reactions. The inert nature of the titanium oxide layer on the electrode surface minimizes unwanted reactions that can consume energy and reduce the efficiency of copper extraction. This selectivity towards the desired copper deposition reaction results in higher current efficiency, meaning that a larger proportion of the applied electrical energy is utilized for copper production rather than being wasted on secondary reactions.

The durability of electrodeposited titanium electrodes also plays a significant role in maintaining process efficiency over time. Unlike traditional electrodes that may degrade or lose effectiveness, titanium electrodes maintain their performance characteristics for extended periods. This consistency eliminates the gradual decline in efficiency often observed with other electrode materials, ensuring that the copper extraction process remains optimized throughout the electrode's lifespan.

Furthermore, the corrosion resistance of electrodeposited titanium electrodes contributes to improved process efficiency by reducing contamination of the electrolyte and the produced copper. This purity preservation is particularly important in applications requiring high-grade copper, as it minimizes the need for additional purification steps, thereby streamlining the overall production process.

The implementation of electrodeposited titanium electrodes can also lead to operational efficiencies beyond the electrochemical process itself. Their longer lifespan reduces the frequency of electrode replacements, minimizing production downtime and associated labor costs. Additionally, the lightweight nature of titanium compared to some traditional electrode materials can simplify handling and maintenance procedures, further contributing to operational efficiency.

It's worth noting that the efficiency improvements offered by electrodeposited titanium electrodes extend beyond copper extraction to other electrochemical processes. For instance, in water treatment applications, these electrodes have shown promise in enhancing the efficiency of pollutant removal and disinfection processes. Their stability in various electrolytes makes them versatile candidates for a wide range of industrial electrochemical applications, each benefiting from the improved efficiency characteristics.

In conclusion, electrodeposited titanium electrodes have demonstrated remarkable durability and longevity in various electrochemical applications, particularly in copper electrowinning processes. Their superior corrosion resistance, enhanced electrical properties, and stability under harsh operating conditions make them an attractive alternative to traditional electrode materials. The advantages of using these electrodes extend beyond mere longevity, encompassing improved process efficiency, reduced contamination, and potential cost savings in the long run. As industries continue to seek more efficient and sustainable solutions, electrodeposited titanium electrodes are likely to play an increasingly important role in advancing electrochemical technologies and processes.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References

1. Wang, J., & Zhang, B. (2020). Electrodeposited titanium electrodes for copper electrowinning: A comprehensive review. Hydrometallurgy, 197, 105484.

2. Chen, G., et al. (2019). Corrosion behavior of electrodeposited titanium electrodes in acidic media. Journal of Electrochemical Society, 166(11), C3179.

3. Liu, Y., et al. (2018). Efficiency improvement in copper electrowinning using novel titanium-based electrodes. Minerals Engineering, 125, 185-193.

4. Smith, R. D., & Johnson, K. L. (2021). Advances in electrode materials for electrometallurgy: Focus on titanium-based anodes. JOM, 73(5), 1456-1468.

5. Zhang, X., et al. (2017). Electrodeposition of titanium dioxide: Fundamentals and applications. Chemical Reviews, 117(5), 5298-5341.

6. Brown, A. C., & Wilson, B. P. (2022). Comparative study of electrode materials for copper recovery: Traditional vs. novel approaches. Hydrometallurgy, 208, 105891.

7. Fernández-Marchante, C. M., et al. (2020). Electrochemical characterization of electrodeposited titanium anodes for water treatment applications. Electrochimica Acta, 354, 136749.

8. Thompson, M., et al. (2019). Life cycle assessment of electrode materials in copper electrowinning. Resources, Conservation and Recycling, 148, 181-191.

9. Li, H., et al. (2021). Recent progress in the development of durable anodes for copper electrowinning. Journal of Applied Electrochemistry, 51(3), 339-355.

10. Rodrigues, S., & Romano, P. (2018). Electrochemical technologies for metal recovery and environmental remediation. Metals, 8(9), 731.

Related Industry Knowledge

- How Does a DSA Anode Revolutionize Electrochemical Processes?

- What Advantages Do Electrodeposited Titanium Electrodes Offer for Cobalt Plating?

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- Why Should You Consider Titanium Electrodes for Copper Plating?

- How Can Titanium Electrode Improve Nickel And Cobalt Electrodeposition Performance?

- Why is Semiconductor Plating Crucial for Modern Electronics? Understanding the Process and Benefits

- How Does Gold Plating Enhance PCB Performance? An In-Depth Exploration