- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electrodeposited Titanium Electrode for Copper

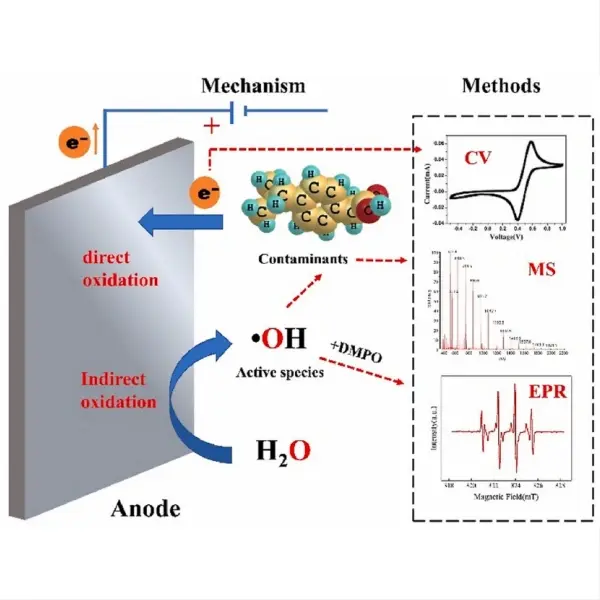

Product Overview: It has good electrical conductivity, combined with the high strength and corrosion resistance of industrial pure titanium, to prepare a new titanium-based lead dioxide anode.

The titanium-based lead dioxide anode developed by Taijin Company can replace pure lead anode, lead-tin, or lead-antimony alloy anode, and precious metal anode in the field of hydrometallurgy.

Product features: When electrolyzed in the electrolyte, it has strong oxidation ability, corrosion resistance, a small amount of lead dissolution, good conductivity, and the ability to pass large currents.

Product advantages: Compared with traditional lead anodes, the current efficiency can be increased by 2%, the lead dissolution rate is reduced by 99%, the service life is extended by 1 year, and the comprehensive use cost is reduced by 1%.

Application conditions: PH<4, sulfuric acid<500g/L, temperature<80℃, F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.

Application areas: electrolytic nickel, electrolytic zinc, electrolytic copper.

1. What is an electrodeposited titanium electrode for copper?

The electrodeposited titanium electrode for copper, offered by TJNE, is a high-quality and efficient solution for various copper electroplating applications. electrode is designed to give superior performance and continuity, icing high-quality bobby plating results.

The electrode's structure consists of a titanium substrate with a thin subcaste of high-quality essence coating on its face. This coating provides excellent conductivity and erosion resistance, making it ideal for bobby electroplating processes. The electrode's unique structure and parcels enable precise control over the plating process and ensure invariant bobby deposit.

The working principle of the electrode involves the electrochemical response between the bobby ions in the plating result and the electrode face. The titanium substrate acts as the cathode, while the bobby ions are reduced and deposited onto the face of the electrode. This electrodeposition process ensures effective and harmonious bobby plating results.

The electrode is composed of a titanium substrate, an essence coating( similar to platinum, gold, etc.), and a defensive sub-caste. The titanium substrate provides mechanical strength and stability, while the essence coating enhances the electrode's electrical conductivity. The defensive subcaste ensures long-lasting performance by precluding erosion and declination.

The electrode's crucial features include high effectiveness, excellent erosion resistance, superior conductivity, and precise control over the plating process. These characteristics allow for high-quality bobby plating with invariant consistency and excellent adhesion. The electrode also offers a long service life and can repel harsh operating conditions.

2. System Composition and Economic Indicators:

Table showing the components and economic indicators of the electrode system:

| Component | Economic Indicator |

|---|---|

| Titanium substrate | Cost-effective |

| Metal coating | High electrical conductivity |

| Protective layer | Extended electrode life |

3. Performance Parameters:

Table showing the performance parameters of the electrode:

| Parameter | Value |

|---|---|

| Corrosion resistance | Excellent |

| Conductivity | High |

| Plating thickness control | Precise |

| Adhesion | Excellent |

| Service life | Long |

4. Economic Indicators and Key Features:

The electrodeposited titanium electrode for copper offers significant economic advantages, as it provides efficient copper electroplating with precise control over thickness, reducing material and energy wastage. Its excellent corrosion resistance ensures longer electrode life, reducing replacement costs. The electrode's superior conductivity improves plating efficiency and reduces operation time. The electrode's key features, including high efficiency and excellent adhesion, make it an ideal choice for demanding copper electroplating applications.

5. Application Areas:

The electrode is widely used in various industries such as electronics, automotive, aerospace, and decorative plating. It is suitable for copper plating applications that require high-quality results, uniform thickness, and excellent adhesion. The electrode's versatility and superior performance make it an essential component in electroplating processes.

6. FAQ:

Here are some frequently asked questions about our electrodeposited titanium electrode:

Q: Can the electrode be used for other metal plating processes?

A: The electrode is specifically designed for copper electroplating but can be customized for other metals as well.

Q: What is the typical thickness range achievable with this electrode?

A: The electrode allows precise control over the plating thickness, ranging from a few microns to several millimeters.

Q: Is the electrode compatible with different plating solutions?

A: Yes, the electrode is compatible with a wide range of copper plating solutions and can be adapted to specific requirements.

For more information or to inquire about our electrodeposited titanium electrode for copper, please contact us at yangbo@tjanode.com. We are a professional manufacturer and supplier with strong technical expertise and complete after-sales service. We offer fast delivery, secure packaging, and support for testing and certification. Choose TJNE for your electrodeposited titanium electrode needs!