- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

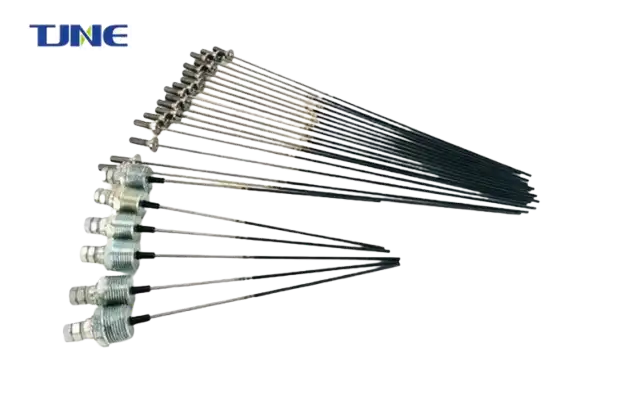

Mixed Metal Oxide (MMO) Titanium Probe Anodes have gained significant attention in the field of cathodic protection due to their unique properties and performance characteristics. These anodes are designed to provide superior corrosion protection for various structures and equipment in challenging environments. As the demand for more efficient and durable cathodic protection systems continues to grow, it's essential to understand how MMO Titanium Probe Anodes stack up against other anode types. This blog post will explore the key features, advantages, and considerations of MMO Titanium Probe Anodes in comparison to alternative anode materials.

What are the advantages of using MMO Titanium Probe Anodes in cathodic protection systems?

MMO Titanium Probe Anodes offer several distinct advantages over traditional anode materials, making them an attractive choice for many cathodic protection applications. These anodes are engineered to provide exceptional performance and longevity, which can significantly impact the overall effectiveness and cost-efficiency of a cathodic protection system.

One of the primary advantages of MMO Titanium Probe Anodes is their high current output capacity. The mixed metal oxide coating on the titanium substrate allows for a much higher current density compared to conventional anodes. This increased current output means that fewer anodes are required to achieve the same level of protection, potentially reducing installation costs and simplifying system design.

Another significant benefit of MMO Titanium Probe Anodes is their excellent dimensional stability. Unlike some traditional anode materials that can experience substantial consumption or shape changes over time, MMO anodes maintain their form throughout their operational life. This stability ensures consistent performance and eliminates the need for frequent replacements or adjustments to the cathodic protection system.

The versatility of MMO Titanium Probe Anodes is also noteworthy. These anodes can be used in a wide range of environments, including seawater, freshwater, and soil applications. Their resistance to various chemical compounds makes them suitable for use in aggressive environments where other anode materials might quickly deteriorate.

Furthermore, MMO Titanium Probe Anodes exhibit low dissolution rates, which contributes to their extended lifespan. This characteristic not only reduces the frequency of anode replacements but also minimizes the environmental impact associated with anode consumption and disposal.

The lightweight nature of titanium as a base material offers additional advantages in terms of handling and installation. MMO Titanium Probe Anodes are easier to transport and manipulate compared to heavier alternatives like high-silicon cast iron anodes, potentially reducing labor costs and installation time.

Lastly, the uniform current distribution provided by MMO Titanium Probe Anodes enhances the overall effectiveness of the cathodic protection system. This uniform distribution ensures that all areas of the protected structure receive adequate protection, minimizing the risk of localized corrosion or under-protected zones.

How does the lifespan of MMO Titanium Probe Anodes compare to traditional anodes?

The lifespan of anodes is a critical factor in the design and maintenance of cathodic protection systems. MMO Titanium Probe Anodes have gained a reputation for their exceptional longevity compared to many traditional anode materials. Understanding the factors that contribute to this extended lifespan and how it compares to other anode types is essential for making informed decisions in cathodic protection system design.

MMO Titanium Probe Anodes typically have a significantly longer lifespan than traditional anodes such as graphite, high-silicon cast iron, or conventional platinized anodes. While the exact lifespan can vary depending on the specific application and environmental conditions, MMO anodes can often last 20 years or more in many applications. This longevity is in stark contrast to some traditional anodes that may require replacement every 5-10 years or even more frequently in harsh environments.

The extended lifespan of MMO Titanium Probe Anodes can be attributed to several factors. First, the mixed metal oxide coating is highly stable and resistant to wear. This coating is typically composed of precious metal oxides, such as iridium oxide or ruthenium oxide, which have excellent electrocatalytic properties and low dissolution rates. The stability of this coating ensures that the anode maintains its effectiveness over extended periods, even under high current output conditions.

The titanium substrate also plays a crucial role in the longevity of these anodes. Titanium forms a protective oxide layer when exposed to oxygen, making it highly resistant to corrosion. This inherent corrosion resistance of the base material contributes to the overall durability of the anode.

In comparison, traditional anodes often suffer from higher consumption rates. For example, graphite anodes can experience significant erosion over time, especially in high-velocity environments. High-silicon cast iron anodes, while durable, still have higher consumption rates than MMO anodes and may require more frequent replacement.

It's important to note that the lifespan of any anode, including MMO Titanium Probe Anodes, can be influenced by various factors such as current density, electrolyte composition, temperature, and flow conditions. However, even under challenging conditions, MMO anodes typically outperform traditional materials in terms of longevity.

The extended lifespan of MMO Titanium Probe Anodes offers several benefits beyond just reduced replacement frequency. It contributes to lower lifecycle costs for cathodic protection systems, as the need for anode replacement and associated maintenance is significantly reduced. This can be particularly advantageous in applications where access for maintenance is difficult or costly, such as offshore structures or buried pipelines.

Additionally, the consistent performance of MMO anodes throughout their lifespan ensures more reliable protection for the structure. Traditional anodes may experience a decline in effectiveness as they consume, potentially leading to periods of inadequate protection before replacement. The stable performance of MMO anodes helps maintain consistent protection levels over extended periods.

What factors should be considered when choosing between MMO Titanium Probe Anodes and other anode materials?

Selecting the appropriate anode material for a cathodic protection system is a critical decision that can significantly impact the system's effectiveness, longevity, and overall cost-efficiency. When considering MMO Titanium Probe Anodes versus other anode types, several key factors should be carefully evaluated to ensure the best choice for the specific application.

Initial cost is often one of the first considerations in any engineering decision. MMO Titanium Probe Anodes typically have a higher upfront cost compared to traditional anode materials like graphite or high-silicon cast iron. However, it's crucial to consider the total lifecycle cost rather than just the initial investment. The extended lifespan and reduced maintenance requirements of MMO anodes can often result in lower long-term costs, especially in applications where anode replacement is challenging or expensive.

The specific environment in which the anode will operate is another critical factor. MMO Titanium Probe Anodes excel in a wide range of environments, including seawater, freshwater, and soil applications. They are particularly well-suited for aggressive environments with high chloride content or extreme pH levels. In contrast, some traditional anodes may have limitations in certain environments. For example, graphite anodes can be brittle and may not be suitable for high-flow or turbulent conditions.

Current output requirements should also be carefully considered. MMO Titanium Probe Anodes can operate at much higher current densities compared to many traditional anodes. This high current output capacity can be advantageous in applications requiring significant current for adequate protection or where space for anode installation is limited. However, if the required current output is relatively low, a simpler and less expensive anode material might be sufficient.

The expected service life of the protected structure is another important consideration. For long-term projects or structures with designed lifespans of several decades, the longevity of MMO Titanium Probe Anodes can be a significant advantage. Their ability to provide consistent protection over extended periods aligns well with the needs of critical infrastructure projects. Conversely, for temporary structures or short-term applications, the additional cost of MMO anodes may not be justified.

System design complexity is also a factor to consider. The high current output of MMO Titanium Probe Anodes often means that fewer anodes are required to achieve the desired level of protection. This can simplify system design and reduce installation costs. However, it's essential to ensure that the cathodic protection system is designed to take full advantage of the MMO anodes' capabilities to justify their use.

Environmental considerations should not be overlooked. MMO Titanium Probe Anodes have very low dissolution rates, which means they introduce fewer metal ions into the surrounding environment over time compared to sacrificial anodes. This can be an important factor in environmentally sensitive areas or where regulatory compliance is a concern.

Maintenance requirements and accessibility for replacement should also be evaluated. The long lifespan and stability of MMO Titanium Probe Anodes can be particularly beneficial in remote or difficult-to-access locations where frequent maintenance is impractical or costly. However, if easy access for anode replacement is available and maintenance costs are not a significant concern, simpler anode systems might be considered.

Lastly, the specific industry standards and regulations applicable to the project should be considered. Some industries or applications may have specific requirements or preferences for certain anode types. Ensuring compliance with relevant standards and best practices is essential when selecting any cathodic protection components.

In conclusion, MMO Titanium Probe Anodes offer significant advantages in terms of longevity, performance, and versatility compared to many traditional anode types. Their superior current output capacity, dimensional stability, and resistance to harsh environments make them an excellent choice for many cathodic protection applications. However, the decision to use MMO anodes should be based on a careful evaluation of the specific project requirements, environmental conditions, and long-term cost considerations. By weighing these factors carefully, engineers and project managers can make informed decisions that ensure optimal corrosion protection and cost-effectiveness for their cathodic protection systems.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. NACE International. (2013). Cathodic Protection Design. Houston, TX: NACE International.

2. Baeckmann, W. V., Schwenk, W., & Prinz, W. (1997). Handbook of Cathodic Corrosion Protection. Gulf Professional Publishing.

3. Revie, R. W. (2015). Uhlig's Corrosion Handbook. John Wiley & Sons.

4. DNV GL. (2017). Cathodic Protection Design. Recommended Practice DNVGL-RP-B401.

5. Tezdogan, T., & Demirel, Y. K. (2014). An overview of marine corrosion protection with a focus on cathodic protection and coatings. Brodogradnja, 65(2), 49-59.

6. Gurrappa, I. (2005). Cathodic protection of cooling water systems and selection of appropriate materials. Journal of Materials Processing Technology, 166(2), 256-267.

7. Cuccia, L., & Gurrappa, I. (2011). Surface Engineering for Corrosion and Wear Resistance. ASM International.

8. Shreir, L. L., Jarman, R. A., & Burstein, G. T. (1994). Corrosion: Metal/Environment Reactions. Butterworth-Heinemann.

9. Cicek, V. (2014). Cathodic Protection: Industrial Solutions for Protecting Against Corrosion. John Wiley & Sons.

10. Roberge, P. R. (2008). Corrosion Engineering: Principles and Practice. McGraw-Hill Education.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection