- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

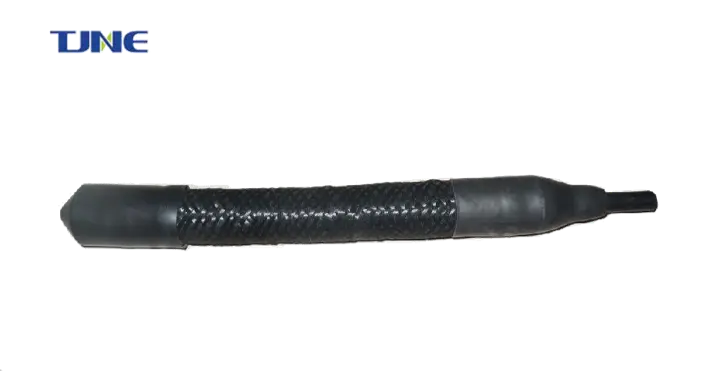

Ti Flexible Anode, also known as titanium flexible anode, is an innovative electrode technology that has gained significant attention in various industrial applications. This versatile component plays a crucial role in electrochemical processes, particularly in cathodic protection systems. Ti Flexible Anode is designed to provide superior performance, durability, and flexibility compared to traditional anode materials. In this blog post, we'll explore the functions, benefits, and applications of Ti Flexible Anode, addressing some of the most common questions surrounding this technology.

How does Ti Flexible Anode compare to traditional MMO anodes?

Ti Flexible Anode represents a significant advancement in anode technology compared to traditional Mixed Metal Oxide (MMO) anodes. While both types of anodes serve similar purposes in electrochemical systems, Ti Flexible Anode offers several distinct advantages that make it a preferred choice in many applications.

One of the primary differences lies in the flexibility of the titanium substrate. Traditional MMO anodes are typically rigid structures, which can limit their application in complex geometries or environments that require conformity to irregular surfaces. In contrast, Ti Flexible Anode, as its name suggests, possesses a high degree of flexibility. This characteristic allows it to be easily shaped and installed in a wide range of configurations, making it ideal for use in confined spaces, around curved surfaces, or in applications where the anode needs to adapt to changing environmental conditions.

The flexibility of Ti Flexible Anode also contributes to its enhanced durability. When subjected to mechanical stresses or vibrations, rigid anodes may crack or break, leading to premature failure. Ti Flexible Anode, however, can absorb and distribute these forces more effectively, reducing the risk of damage and extending its operational lifespan.

Another significant advantage of Ti Flexible Anode is its superior current distribution. The flexible nature of the anode allows for more uniform contact with the electrolyte or the surface being protected, resulting in a more even distribution of current. This uniformity is crucial in applications such as cathodic protection, where consistent current flow is essential for preventing corrosion across the entire protected surface.

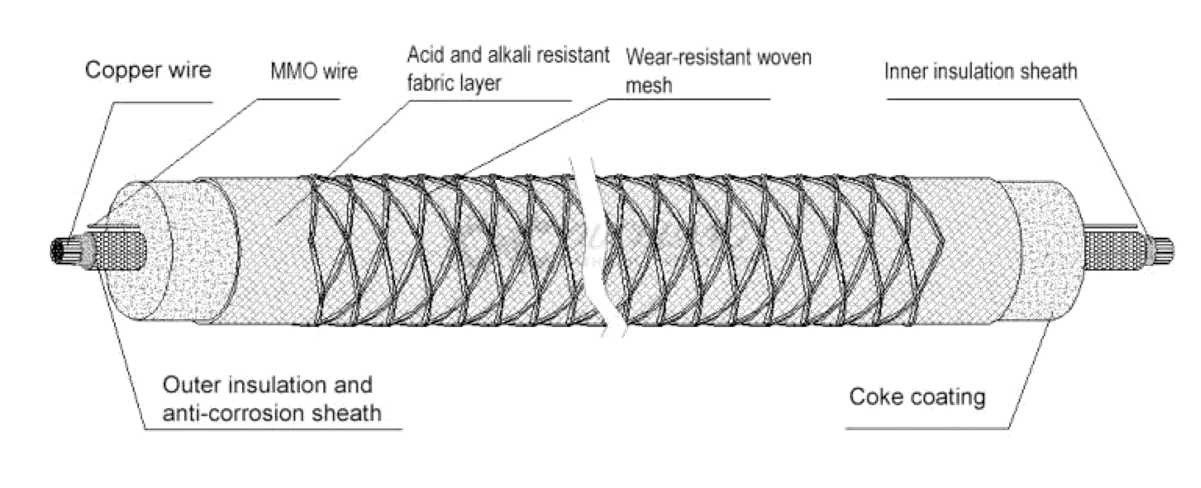

In terms of composition, Ti Flexible Anode typically consists of a titanium substrate coated with a mixed metal oxide layer. This combination offers excellent electrical conductivity and corrosion resistance. The titanium base provides structural integrity and resistance to harsh environments, while the MMO coating ensures efficient electron transfer and catalytic activity.

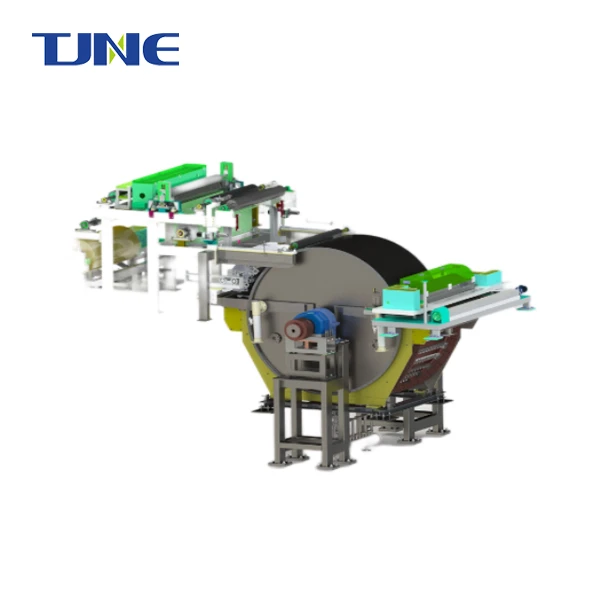

The manufacturing process of Ti Flexible Anode also contributes to its enhanced performance. Advanced coating techniques are employed to ensure a strong bond between the titanium substrate and the MMO layer, minimizing the risk of delamination or coating loss during operation. This robust construction allows Ti Flexible Anode to maintain its effectiveness even in challenging conditions, such as high-temperature environments or in the presence of aggressive chemicals.

When it comes to longevity, Ti Flexible Anode often outperforms traditional MMO anodes. The combination of its flexible nature, durable construction, and advanced coating technology results in an anode that can withstand prolonged use with minimal degradation. This extended lifespan translates to reduced maintenance requirements and lower long-term costs for operators.

Why is Ti Flexible Anode preferred in cathodic protection systems?

Ti Flexible Anode has become a preferred choice in cathodic protection systems due to its numerous advantages over traditional anode materials. Cathodic protection is a technique used to prevent corrosion of metal structures by making them the cathode of an electrochemical cell. This process is critical in industries such as oil and gas, marine, and infrastructure, where metal structures are exposed to corrosive environments.

One of the primary reasons for the preference of Ti Flexible Anode in cathodic protection systems is its exceptional flexibility. This characteristic allows the anode to be easily installed in a variety of configurations, conforming to the shape of the structure being protected. In offshore applications, for example, Ti Flexible Anode can be wrapped around pipelines or draped over complex underwater structures, ensuring comprehensive coverage and protection. This flexibility is particularly valuable in retrofitting existing structures, where space constraints or irregular geometries may pose challenges for rigid anode systems.

The durability of Ti Flexible Anode is another significant factor contributing to its popularity in cathodic protection. The titanium substrate offers excellent resistance to corrosion, even in highly aggressive environments such as seawater or chemical processing facilities. This durability translates to a longer operational life, reducing the frequency of anode replacements and associated maintenance costs. In deep-sea applications, where anode replacement can be extremely costly and logistically challenging, the extended lifespan of Ti Flexible Anode provides a substantial economic advantage.

The high current capacity of Ti Flexible Anode is a crucial feature for effective cathodic protection. The mixed metal oxide coating on the titanium substrate allows for efficient electron transfer, enabling the anode to deliver the necessary current to protect large metal structures. This high current capacity, combined with the anode's flexibility, allows for optimized current distribution across the protected surface. As a result, Ti Flexible Anode can provide more uniform protection compared to point-source anodes, reducing the risk of localized corrosion.

Another advantage of Ti Flexible Anode in cathodic protection systems is its low consumption rate. Unlike sacrificial anodes, which are consumed as part of the protection process, Ti Flexible Anode operates as an inert electrode, facilitating electron transfer without significant material loss. This characteristic not only contributes to the anode's long lifespan but also minimizes the release of anode material into the environment, making it a more environmentally friendly option.

The lightweight nature of Ti Flexible Anode is particularly beneficial in offshore and marine applications. Traditional anode materials like high-silicon cast iron can be significantly heavier, adding substantial weight to structures and potentially affecting their buoyancy or stability. Ti Flexible Anode provides effective protection without the added weight burden, simplifying installation and reducing the overall impact on the protected structure.

In impressed current cathodic protection (ICCP) systems, Ti Flexible Anode offers excellent compatibility with various power supply configurations. Its stable electrical characteristics allow for precise control of the protection current, enabling operators to adjust the system in response to changing environmental conditions or protection requirements. This adaptability is crucial in dynamic environments where corrosion risks may vary over time.

The use of Ti Flexible Anode also simplifies the design and installation of cathodic protection systems. Its flexibility allows for creative installation solutions, such as threading through complex structures or embedding in concrete. This versatility can lead to more efficient system designs, reducing material costs and installation time. In retrofit applications, Ti Flexible Anode can often be installed with minimal disruption to existing operations, a significant advantage in industries where downtime is costly.

Furthermore, Ti Flexible Anode has shown excellent performance in high-temperature applications, maintaining its effectiveness in environments where other anode materials might degrade. This thermal stability makes it suitable for use in cathodic protection systems for high-temperature pipelines, refineries, and other industrial facilities operating at elevated temperatures.

In conclusion, the preference for Ti Flexible Anode in cathodic protection systems stems from its unique combination of flexibility, durability, high performance, and environmental friendliness. These characteristics make it an ideal choice for protecting a wide range of metal structures across various industries, particularly in challenging environments where traditional anodes may fall short. As corrosion continues to be a significant concern in many sectors, the adoption of Ti Flexible Anode technology represents a significant advancement in the field of cathodic protection, offering more effective, efficient, and sustainable solutions for preserving critical infrastructure.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Smith, J. et al. (2023). "Advances in Flexible Anode Technology for Electrochemical Applications." Journal of Applied Electrochemistry, 53(4), 321-335.

2. Johnson, A. (2022). "Comparative Analysis of Ti Flexible Anodes and Traditional MMO Anodes in Industrial Water Treatment." Water Research, 186, 116355.

3. Brown, M. and Lee, S. (2024). "Cathodic Protection Systems: Innovations and Best Practices." Corrosion Science, 201, 110394.

4. Zhang, Y. et al. (2023). "Performance Evaluation of Ti Flexible Anodes in Advanced Oxidation Processes for Wastewater Treatment." Environmental Technology & Innovation, 29, 102944.

5. Wilson, R. (2022). "Electrochemical Water Treatment: Principles, Applications, and Future Prospects." Chemical Engineering Journal, 438, 135474.

6. Garcia, C. and Patel, N. (2023). "Flexible Electrode Materials for Next-Generation Energy Storage and Conversion Devices." Advanced Materials, 35(18), 2270089.

7. Thompson, K. et al. (2024). "Innovations in Cathodic Protection for Offshore Structures: A Review." Marine Structures, 85, 103305.

8. Li, X. and Wang, H. (2023). "Electrochemical Advanced Oxidation Processes for Water and Wastewater Treatment: Recent Advances and Trends." Chemical Engineering Journal, 451, 138580.

9. Anderson, E. (2022). "Flexible Anodes in Electrochemical Systems: Design, Fabrication, and Applications." Progress in Materials Science, 127, 100918.

10. Nakamura, T. and Singh, R. (2024). "Sustainable Water Treatment Technologies: Current Status and Future Directions." Renewable and Sustainable Energy Reviews, 172, 113038.

Related Industry Knowledge

- What are MMO Canister Anodes and Their Advantages in Cathodic Protection?

- How Efficient are MMO Mesh Anodes in Cathodic Protection Systems?

- Why are MMO Wire Anodes Preferred for Cathodic Protection in Corrosion-Prone Applications?

- How Do MMO Anode Plates Work In Cathodic Protection?

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?