- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mixed Metal Oxide/Titanium (MMO/Ti) anodes have gained significant attention in various electrochemical applications due to their unique properties and performance characteristics. As industries continue to seek more efficient and durable electrode materials, understanding how MMO/Ti compares to other anode types becomes crucial. This blog post delves into the advantages, applications, and comparisons of MMO/Ti anodes, providing insights into why they are increasingly preferred in many electrochemical processes.

What are the key advantages of MMO/Ti Flexible Anodes?

MMO/Ti Flexible Anodes offer several distinct advantages that set them apart from traditional anode materials. These benefits stem from their unique composition and structure, which combines the durability of titanium with the electrocatalytic properties of mixed metal oxides.

One of the primary advantages of MMO/Ti Flexible Anodes is their exceptional corrosion resistance. The titanium substrate provides a stable base that resists degradation in harsh chemical environments, while the mixed metal oxide coating enhances the anode's electrochemical performance. This combination results in an anode that can withstand aggressive electrolytes and maintain its integrity over extended periods, significantly reducing the need for frequent replacements and associated downtime.

Another key benefit is the high electrocatalytic activity of MMO/Ti anodes. The mixed metal oxide coating, typically composed of oxides of precious metals like iridium, ruthenium, or tantalum, offers low overpotential for various electrochemical reactions. This translates to improved energy efficiency in processes such as water treatment, chlorine production, and metal recovery. The ability to tailor the composition of the oxide coating allows for optimization of the anode's performance for specific applications, providing versatility that many other anode types cannot match.

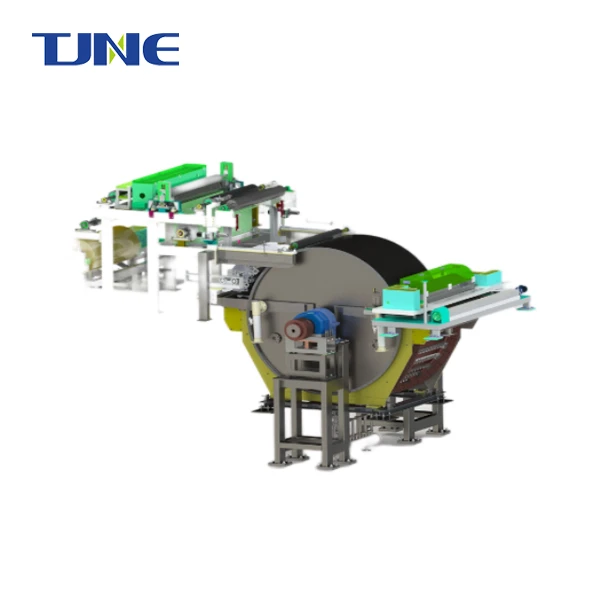

Flexibility is a unique feature of MMO/Ti anodes that significantly expands their application range. Unlike rigid anodes, flexible MMO/Ti anodes can conform to various geometries, making them ideal for use in complex reactor designs or uneven surfaces. This flexibility not only simplifies installation but also ensures more uniform current distribution, leading to improved process efficiency and product quality in electrochemical systems.

The longevity of MMO/Ti anodes is another notable advantage. Their robust construction and resistance to dimensional changes during operation result in a longer service life compared to many other anode materials. This durability translates to reduced maintenance costs and improved reliability in industrial applications where continuous operation is critical.

Furthermore, MMO/Ti anodes exhibit excellent dimensional stability. Unlike some anode materials that may swell, warp, or erode over time, MMO/Ti anodes maintain their shape and dimensions throughout their operational life. This stability ensures consistent performance and simplifies the design and maintenance of electrochemical systems.

The lightweight nature of MMO/Ti anodes, particularly in their flexible form, offers advantages in terms of ease of handling and installation. This characteristic is especially beneficial in applications where weight is a concern, such as in portable water treatment systems or in retrofitting existing facilities where structural load limitations may be a factor.

Lastly, the environmental impact of MMO/Ti anodes is generally lower compared to some alternative materials. Their long lifespan reduces the frequency of replacements, and the materials used in their construction are often recyclable. Additionally, their high efficiency in various electrochemical processes can lead to reduced energy consumption and improved overall environmental performance of the systems in which they are employed.

How does the cost-effectiveness of MMO/Ti compare to traditional anodes?

The cost-effectiveness of MMO/Ti anodes compared to traditional anode materials is a critical consideration for industries looking to optimize their electrochemical processes. While the initial investment in MMO/Ti anodes may be higher than some conventional alternatives, a comprehensive analysis reveals that they often provide superior long-term economic benefits.

To begin with, the upfront cost of MMO/Ti anodes is typically higher than that of traditional materials like graphite or lead anodes. This is primarily due to the use of precious metals in the mixed metal oxide coating and the sophisticated manufacturing processes involved. However, it's essential to evaluate this cost in the context of the anode's entire lifecycle and its impact on the overall process economics.

One of the most significant factors contributing to the cost-effectiveness of MMO/Ti anodes is their exceptional durability and longevity. Traditional anodes often require frequent replacements due to wear, corrosion, or performance degradation. In contrast, MMO/Ti anodes can operate for extended periods without significant loss of efficiency or physical integrity. This longevity translates directly into reduced downtime for anode replacement, lower labor costs associated with maintenance, and decreased frequency of capital expenditure for new anodes.

The operational efficiency of MMO/Ti anodes also plays a crucial role in their cost-effectiveness. Their high electrocatalytic activity allows for lower operating voltages compared to many traditional anodes. This reduction in energy consumption can lead to substantial savings over time, especially in energy-intensive processes like chlor-alkali production or wastewater treatment. In industries where energy costs represent a significant portion of operational expenses, the improved efficiency of MMO/Ti anodes can result in a relatively quick return on investment.

Another aspect to consider is the versatility of MMO/Ti anodes. Their ability to perform efficiently across a wide range of applications means that industries can standardize on a single anode type for multiple processes. This standardization can lead to economies of scale in procurement, simplified inventory management, and reduced training requirements for maintenance personnel.

The dimensional stability of MMO/Ti anodes contributes to their cost-effectiveness by ensuring consistent performance over time. Traditional anodes that are prone to warping or erosion may lead to uneven current distribution, reduced process efficiency, and potential quality issues in the final product. The stability of MMO/Ti anodes helps maintain optimal process conditions, potentially reducing waste and improving product quality, which indirectly contributes to cost savings.

In environmental applications, such as wastewater treatment or soil remediation, the superior performance of MMO/Ti anodes can lead to faster treatment times and more complete contaminant removal. This efficiency can result in significant cost savings, especially in large-scale operations where treatment time and thoroughness directly impact operational costs and regulatory compliance.

The recyclability of MMO/Ti anodes at the end of their service life is another factor that enhances their overall cost-effectiveness. While the initial investment includes precious metals, a significant portion of these materials can be recovered and reused, offsetting some of the original costs and aligning with circular economy principles.

It's important to note that the cost-effectiveness of MMO/Ti anodes can vary depending on the specific application and operating conditions. In some cases, such as short-term projects or applications with less demanding environments, traditional anodes might still be more economical. However, for long-term, continuous operations in harsh conditions, MMO/Ti anodes often prove to be the more cost-effective choice.

What are the primary applications where MMO/Ti outperforms other anode materials?

MMO/Ti anodes have found widespread adoption across various industries due to their unique combination of properties. There are several key applications where these anodes consistently outperform other materials, showcasing their versatility and effectiveness.

One of the primary areas where MMO/Ti anodes excel is in water and wastewater treatment. In this field, these anodes have revolutionized electrochemical oxidation processes for the removal of organic pollutants, pathogens, and other contaminants. The high oxygen evolution overpotential of MMO/Ti anodes promotes the formation of powerful oxidizing species like hydroxyl radicals, which can effectively break down even recalcitrant organic compounds. This capability makes them particularly valuable in treating industrial effluents containing complex organic pollutants that are resistant to conventional treatment methods.

In municipal wastewater treatment, MMO/Ti anodes have shown superior performance in disinfection processes. Their ability to generate mixed oxidants in situ, including chlorine species and ozone, provides a multi-barrier approach to pathogen inactivation. This not only ensures more comprehensive disinfection but also reduces the need for additional chemical treatments, simplifying the overall treatment process and potentially lowering operational costs.

The chlor-alkali industry is another sector where MMO/Ti anodes have become the standard, outperforming traditional materials like graphite. In chlorine production, these anodes offer several advantages, including lower overpotential for chlorine evolution, which translates to significant energy savings. Their resistance to chlorine attack ensures a longer operational life, reducing the frequency of shutdowns for anode replacement. Moreover, the dimensional stability of MMO/Ti anodes contributes to consistent product quality, a critical factor in this industry.

In the field of cathodic protection, MMO/Ti anodes have emerged as a superior alternative to traditional materials like high-silicon cast iron or graphite. Their application in impressed current cathodic protection (ICCP) systems for pipelines, storage tanks, and marine structures has shown remarkable results. The low consumption rate of MMO/Ti anodes means they can provide protection for decades with minimal maintenance. Their flexibility allows for easy installation in confined spaces or on irregular surfaces, making them ideal for retrofitting existing structures.

The metal finishing and electroplating industries have also benefited significantly from the adoption of MMO/Ti anodes. In processes like electrowinning, where metal ions are recovered from solution, these anodes offer several advantages. Their high current efficiency and ability to operate at high current densities improve the rate of metal deposition. The resistance to passivation and fouling ensures consistent performance over time, crucial for maintaining product quality in electroplating operations.

In the rapidly growing field of electrochemical energy storage, MMO/Ti anodes are playing an increasingly important role. Their application in redox flow batteries, particularly in vanadium redox flow systems, has shown promise. The stability of these anodes in the highly oxidizing environment of the positive electrolyte contributes to the long-term performance and cycle life of these energy storage systems.

Environmental remediation is another area where MMO/Ti anodes have demonstrated superior performance. In soil remediation projects, these anodes are used in electrokinetic processes to remove heavy metals and organic contaminants from soil. Their resistance to corrosion in various soil conditions and ability to generate oxidizing species in situ make them more effective than traditional anode materials in this challenging application.

The production of ozone for water treatment and industrial processes is yet another application where MMO/Ti anodes shine. Their high oxygen evolution overpotential favors the formation of ozone, a powerful oxidant and disinfectant. The durability of these anodes in the presence of ozone, which is highly corrosive to many materials, ensures a stable and efficient ozone generation process.

In the field of electrosynthesis, MMO/Ti anodes are increasingly being used for the production of various chemicals. Their ability to selectively promote certain electrochemical reactions while suppressing others makes them valuable in the synthesis of organic compounds, specialty chemicals, and even in emerging fields like CO2 reduction for the production of value-added chemicals.

Lastly, in seawater electrolysis for the production of sodium hypochlorite (used in ballast water treatment systems), MMO/Ti anodes have proven to be highly effective. Their resistance to the corrosive seawater environment, coupled with efficient chlorine evolution, makes them ideal for this application, outperforming many other anode materials.

In conclusion, MMO/Ti anodes have demonstrated superior performance across a wide range of applications, from water treatment and chlorine production to cathodic protection and energy storage. Their unique combination of durability, efficiency, and versatility continues to drive their adoption in existing industries while also opening up new possibilities in emerging fields of electrochemistry.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References

1. Kraft, A. (2007). Electrochemical Water Disinfection: A Short Review. Platinum Metals Review, 51(1), 31-41.

2. Särkkä, H., Bhatnagar, A., & Sillanpää, M. (2015). Recent developments of electro-oxidation in water treatment - A review. Journal of Electroanalytical Chemistry, 754, 46-56.

3. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

4. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

5. Chaplin, B. P. (2014). Critical review of electrochemical advanced oxidation processes for water treatment applications. Environmental Science: Processes & Impacts, 16(6), 1182-1203.

6. Xu, L., & Deng, J. (2020). Efficient electrochemical advanced oxidation processes for water treatment: A focus on mixed metal oxide anodes. Water Research, 182, 115956.

7. Chen, G. (2004). Electrochemical technologies in wastewater treatment. Separation and Purification Technology, 38(1), 11-41.

8. Jeong, J., Kim, C., & Yoon, J. (2009). The effect of electrode material on the generation of oxidants and microbial inactivation in the electrochemical disinfection processes. Water Research, 43(4), 895-901.

9. Panizza, M., & Cerisola, G. (2005). Application of diamond electrodes to electrochemical processes. Electrochimica Acta, 51(2), 191-199.

10. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

Related Industry Knowledge

- What is the Consumption Rate of MMO Anode Plates?

- What is the Max Current Density of MMO Titanium Mesh Anode?

- What is the Breakdown Voltage of a MMO Titanium Probe Anode?

- What are the Different Types of MMO Wire Anode?

- How do I Choose a MMO Tubular Titanium Anode?

- Which Industries Utilize MMO Anode Plates for Corrosion Protection and Cathodic Protection?

- What are the Applications of MMO Titanium Mesh Anodes?