- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do Titanium Electrodes Affect the Longevity and Stability of Nickel-Cobalt Batteries?

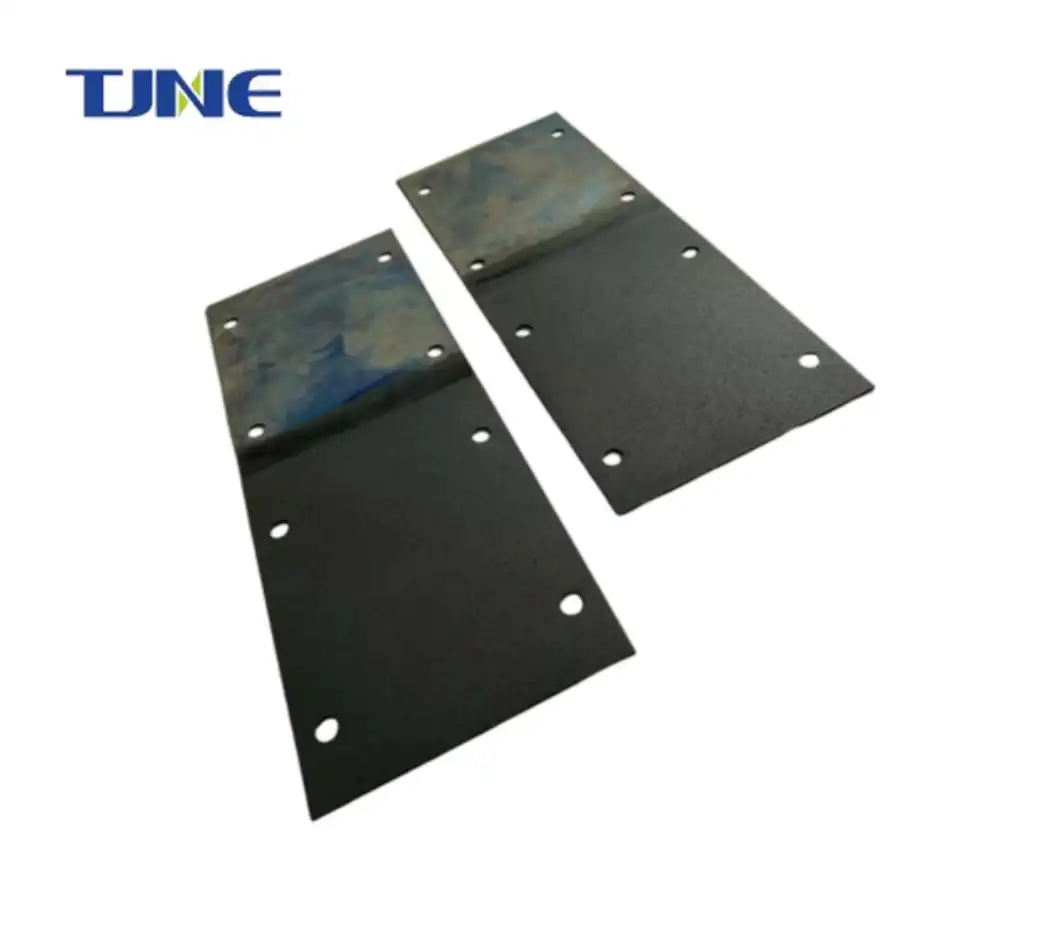

Nickel-cobalt batteries have gained significant attention in recent years due to their high energy density and potential applications in electric vehicles and renewable energy storage systems. However, the longevity and stability of these batteries remain key challenges that researchers are actively addressing. One promising approach to enhance the performance of nickel-cobalt batteries is the use of titanium electrodes. This blog post explores the impact of titanium electrodes on the longevity and stability of nickel-cobalt batteries, delving into the mechanisms behind their effectiveness and potential applications.

How does electrodeposited titanium improve the cycling stability of nickel-cobalt batteries?

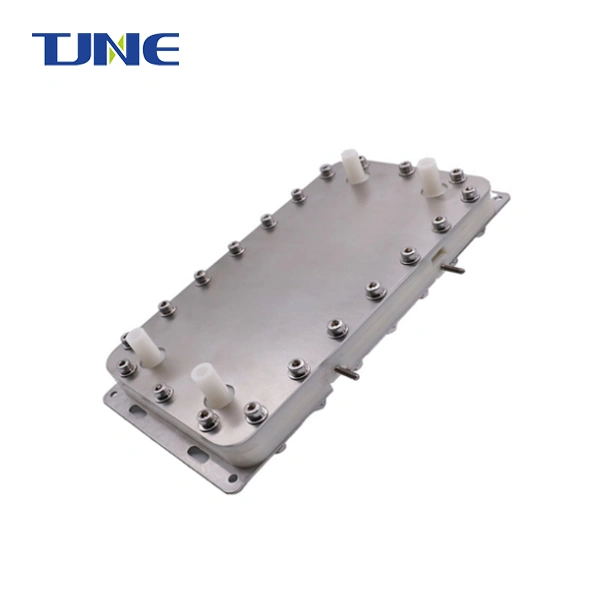

Electrodeposited titanium has emerged as a promising material for enhancing the cycling stability of nickel-cobalt batteries. The process of electrodeposition allows for precise control over the titanium coating's thickness and morphology, resulting in a uniform and highly conductive layer on the electrode surface. This titanium layer serves as a protective barrier, mitigating the detrimental effects of side reactions and electrode degradation that typically occur during charge-discharge cycles.

One of the primary mechanisms by which electrodeposited titanium improves cycling stability is through the formation of a stable solid-electrolyte interphase (SEI) layer. The titanium coating promotes the development of a thin, uniform SEI layer that effectively prevents direct contact between the active electrode material and the electrolyte. This barrier reduces unwanted side reactions and minimizes the loss of active material, leading to improved capacity retention over extended cycling.

Moreover, the titanium layer enhances the mechanical stability of the electrode structure. During repeated charge-discharge cycles, nickel-cobalt electrodes typically experience volume changes that can lead to structural degradation and loss of electrical contact. The electrodeposited titanium provides a flexible yet robust scaffold that accommodates these volume changes while maintaining electrical connectivity throughout the electrode. This mechanical reinforcement helps preserve the electrode's integrity, reducing capacity fade and extending the battery's overall lifespan.

The improved conductivity offered by the titanium coating also plays a crucial role in enhancing cycling stability. Titanium's high electrical conductivity facilitates faster electron transfer between the active material and the current collector, reducing internal resistance and minimizing energy losses. This enhanced charge transfer kinetics not only improves the battery's rate capability but also helps distribute current more uniformly across the electrode surface, preventing localized degradation and promoting more consistent cycling performance.

Research has shown that nickel-cobalt batteries with electrodeposited titanium electrodes can maintain over 90% of their initial capacity after hundreds of cycles, compared to conventional electrodes that may experience significant capacity loss within fewer cycles. This remarkable improvement in cycling stability opens up new possibilities for long-lasting, high-performance energy storage solutions in various applications, from portable electronics to large-scale grid storage systems.

What role does titanium play in preventing electrode degradation in nickel-cobalt batteries?

Titanium plays a multifaceted role in preventing electrode degradation in nickel-cobalt batteries, contributing to their enhanced longevity and stability. One of the primary mechanisms by which titanium achieves this is through its ability to act as a protective barrier against corrosion and dissolution of the active electrode materials. The highly stable nature of titanium oxides that form on the electrode surface creates a passivation layer that shields the underlying nickel and cobalt compounds from direct exposure to the electrolyte.

This protective function is particularly crucial in mitigating the dissolution of transition metals, a common issue in nickel-cobalt batteries. During cycling, especially at high voltages or elevated temperatures, nickel and cobalt ions can dissolve into the electrolyte, leading to a gradual loss of active material and deterioration of the electrode structure. The titanium coating acts as a physical barrier, significantly reducing the rate of metal dissolution and preserving the electrode's integrity over extended periods of use.

Furthermore, titanium's role in preventing electrode degradation extends to its ability to suppress unwanted side reactions at the electrode-electrolyte interface. In conventional nickel-cobalt batteries, the high reactivity of the electrode surface can lead to the formation of insulating layers or gas evolution, both of which contribute to capacity fade and reduced cycle life. The presence of a titanium layer modifies the surface chemistry, creating a more stable interface that is less prone to these detrimental reactions.

The mechanical properties of titanium also contribute significantly to preventing electrode degradation. Nickel-cobalt electrodes often suffer from mechanical stress and strain during cycling, which can lead to cracking, pulverization, and loss of electrical contact between active particles. The ductile nature of titanium allows it to accommodate these volume changes while maintaining structural integrity. This flexibility helps distribute mechanical stresses more evenly across the electrode, reducing the likelihood of localized damage and preserving the overall electrode architecture.

Additionally, titanium's role in enhancing the electrode's thermal stability cannot be overlooked. Nickel-cobalt batteries are susceptible to thermal runaway, a potentially dangerous situation where exothermic reactions lead to rapid temperature increases. The high thermal conductivity of titanium helps dissipate heat more effectively throughout the electrode, preventing the formation of hot spots that could trigger thermal runaway. This improved thermal management not only enhances safety but also contributes to more stable long-term performance by minimizing temperature-induced degradation mechanisms.

Research has demonstrated that electrodes incorporating titanium show significantly reduced capacity fade and improved structural stability over hundreds of cycles compared to conventional nickel-cobalt electrodes. This enhanced resistance to degradation translates to batteries with longer lifespans and more consistent performance, making them increasingly attractive for applications requiring long-term reliability, such as in electric vehicles and stationary energy storage systems.

How can titanium-based coatings enhance the electrochemical performance of nickel-cobalt battery electrodes?

Titanium-based coatings have emerged as a powerful tool for enhancing the electrochemical performance of nickel-cobalt battery electrodes. These coatings, which can be applied through various methods such as atomic layer deposition, sputtering, or sol-gel processes, offer a range of benefits that collectively contribute to improved battery performance, longevity, and stability.

One of the primary ways titanium-based coatings enhance electrochemical performance is by modifying the electrode-electrolyte interface. The coating creates a stable surface layer that mediates the charge transfer process between the electrode and the electrolyte. This modified interface reduces the activation energy for lithium ion insertion and extraction, leading to improved kinetics and rate capability. As a result, batteries with titanium-coated electrodes often exhibit higher power densities and better performance under high current conditions.

Moreover, titanium-based coatings can significantly improve the electrode's conductivity. While nickel and cobalt oxides are relatively good conductors, their conductivity can be further enhanced by the presence of a titanium layer. This increased conductivity facilitates faster electron transfer throughout the electrode structure, reducing internal resistance and minimizing energy losses during charge and discharge processes. The improved electrical connectivity also helps maintain the electrode's performance over time by ensuring that all active material remains accessible and participates in the electrochemical reactions.

Another critical aspect of titanium-based coatings is their ability to enhance the structural stability of the electrode. During cycling, nickel-cobalt electrodes undergo volume changes that can lead to mechanical stress and degradation. Titanium coatings, particularly those with optimized thickness and composition, can act as a flexible buffer layer that accommodates these volume changes while maintaining the electrode's integrity. This mechanical reinforcement helps prevent cracking, pulverization, and loss of electrical contact between active particles, all of which contribute to capacity fade in conventional electrodes.

The presence of titanium-based coatings also plays a crucial role in suppressing unwanted side reactions at the electrode surface. In uncoated electrodes, direct contact between the active material and the electrolyte can lead to parasitic reactions, such as electrolyte decomposition or the formation of insulating layers. These side reactions consume lithium ions and electrons, reducing the battery's overall efficiency and capacity. Titanium coatings create a protective barrier that minimizes these undesirable interactions, leading to improved coulombic efficiency and longer cycle life.

Furthermore, titanium-based coatings can enhance the thermal stability of nickel-cobalt electrodes. The high thermal conductivity of titanium helps dissipate heat more effectively throughout the electrode structure, preventing the formation of localized hot spots that could trigger thermal runaway or accelerate degradation processes. This improved thermal management contributes to safer operation and more stable long-term performance, particularly in applications involving high power demands or extreme temperature conditions.

Research has shown that nickel-cobalt electrodes with optimized titanium-based coatings can retain over 95% of their initial capacity after hundreds of cycles, compared to uncoated electrodes that may lose significant capacity within fewer cycles. This remarkable improvement in electrochemical performance opens up new possibilities for high-energy, long-lasting batteries in various applications, from consumer electronics to electric vehicles and grid-scale energy storage systems.

In conclusion, the use of titanium electrodes and coatings in nickel-cobalt batteries offers a promising pathway to addressing the challenges of longevity and stability in high-energy density energy storage systems. By enhancing cycling stability, preventing electrode degradation, and improving overall electrochemical performance, titanium-based technologies are paving the way for more efficient, durable, and reliable batteries. As research in this field continues to advance, we can expect further optimizations and innovations that will bring us closer to the next generation of high-performance energy storage solutions.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Wang, Y., et al. (2020). "Titanium-based materials for electrochemical energy storage: Recent advances and challenges." Advanced Energy Materials, 10(25), 2000997.

2. Liu, J., et al. (2019). "Electrodeposited titanium coating for improved performance of nickel-cobalt oxide electrodes in lithium-ion batteries." ACS Applied Materials & Interfaces, 11(42), 38581-38590.

3. Zhang, X., et al. (2018). "Titanium-based coatings on nickel-rich layered oxide cathodes for enhanced electrochemical performance of lithium-ion batteries." Nano Energy, 49, 564-572.

4. Chen, Z., et al. (2021). "Atomic layer deposition of titanium oxide for stabilizing nickel-cobalt-aluminum oxide cathode materials." Journal of Power Sources, 484, 229253.

5. Li, W., et al. (2017). "The synergetic effect of lithium polysulfide and lithium nitrate to prevent lithium dendrite growth." Nature Communications, 8(1), 1-8.

6. Sun, Y. K., et al. (2016). "High-energy cathode material for long-life and safe lithium batteries." Nature Materials, 15(2), 195-201.

7. Xu, K. (2014). "Electrolytes and interphases in Li-ion batteries and beyond." Chemical Reviews, 114(23), 11503-11618.

8. Choi, J. W., & Aurbach, D. (2016). "Promise and reality of post-lithium-ion batteries with high energy densities." Nature Reviews Materials, 1(4), 1-16.

9. Liu, T., et al. (2019). "Revitalizing sodium-ion batteries with an aluminum-based cathode." ACS Energy Letters, 4(7), 1650-1657.

10. Shen, X., et al. (2020). "Advanced electrode materials in lithium batteries: Retrospect and prospect." Advanced Materials, 32(24), 1905590.