- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

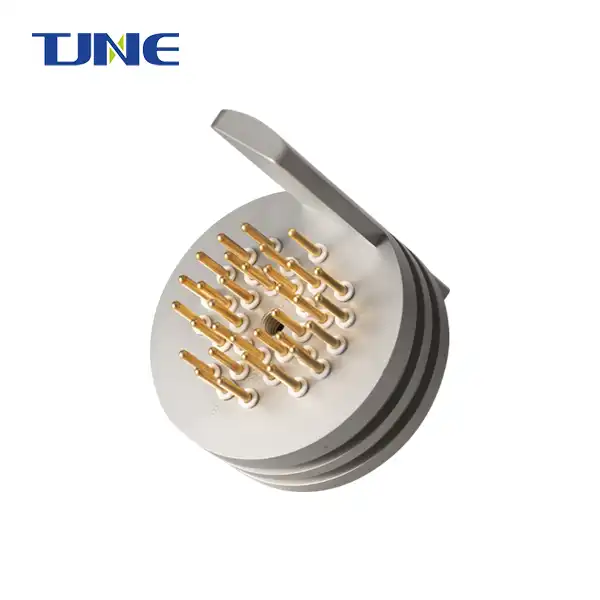

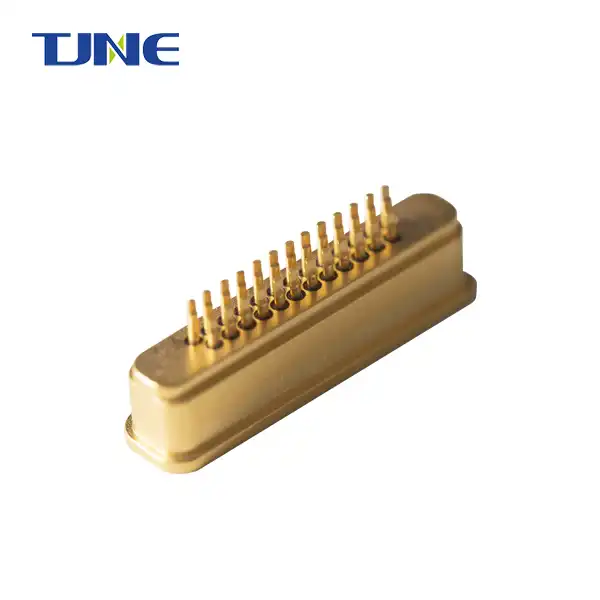

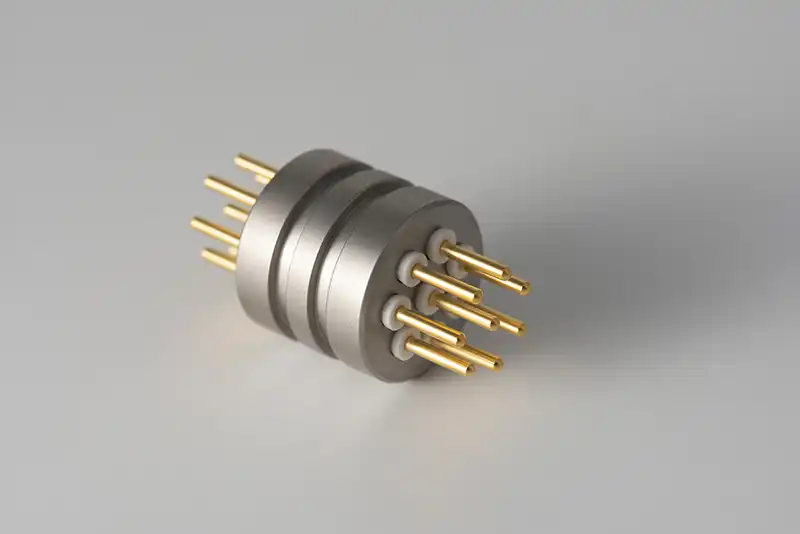

High-Pressure & High-Temperature Hermetic Feedthroughs

Product Overview: High-Pressure & High-Temperature Hermetic Feedthroughs are engineered to withstand harsh environments, including deep-sea exploration, aerospace applications, and industrial processes.

Pressure Rating: Up to 31183psi

Temperature Range: -55°C to 300°C

Leakage Rate: <1.0 x 10^-9 atm cc/s

After-sales service: Providing timely and high-quality worldwide services

Product Details

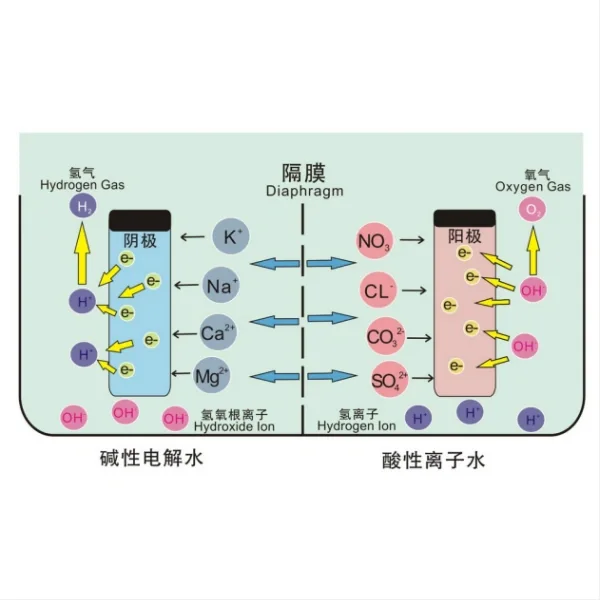

High-Pressure & High-Temperature Hermetic Feedthroughs are critical components used in various industries where sealing integrity under extreme conditions is paramount. These feedthroughs ensure a reliable transfer of signals or power across a high-pressure and high-temperature barrier, maintaining system efficiency and safety.They are engineered to withstand harsh environments, including deep-sea exploration, aerospace applications, and industrial processes. They provide a hermetic seal, preventing leakage and maintaining system integrity in challenging conditions.

Detailed Structure and Characteristics

Structure:

Sealing Component: At the center of a hermetic feedthrough is the fixing component, which gives the obstruction against the section of liquids, gasses, or electrical signals. This component is ordinarily made from materials such as glass, ceramic, or metal, chosen for their capacity to keep up a solid seal beneath tall weights and temperatures.

Feedthrough Body: The feedthrough body houses the fixing component and gives mechanical bolster and security. It is ordinarily built from strong materials such as stainless steel, titanium, or specialized combinations that can withstand the natural conditions of the application.

Characteristics:

Hermetic Fixing: The essential characteristic of high-pressure & high-temperature hermetic feedthroughs is their capacity to give a solid hermetic seal, anticipating spillage of liquids, gasses, or electrical signals over the obstruction. This fixing keenness is basic for keeping up framework execution and safety.

Pressure Resistance: These feedthroughs are outlined to withstand tall weights experienced in different applications, such as deep-sea investigation, aviation, and mechanical forms. They are built to anticipate distortion or disappointment beneath the weight differential over the boundary.

Performance Parameters

|

Parameter |

Value |

|

Pressure Rating |

30458 psi |

|

Temperature Range |

-55°C to 300°C |

|

Leakage Rate |

<1.0 x 10^-9 atm cc/s |

Features and Advantages

Features:

Hermetic Fixing: These feedthroughs are planned to give a hermetic seal, guaranteeing no spillage of liquids, gasses, or electrical signals over the obstruction. This fixing is significant for keeping up framework keenness in high-pressure and high-temperature environments.

Robust Development: High-pressure & high-temperature hermetic feedthroughs are developed from solid materials such as stainless steel, titanium, ceramics, and specialized combinations. This strong development permits them to withstand mechanical push, erosion, and warm cycling.

Advantages:

Reliable Fixing Judgment: The hermetic fixing given by these feedthroughs guarantees dependable operation and framework judgment in challenging situations where spillage seem lead to hardware disappointment or security hazards.

Enhanced Security: By avoiding liquid or gas spillage, they upgrade security in basic applications such as aviation, deep-sea investigation, and mechanical forms where hardware disappointment may have genuine results.

Application Fields

Oil and Gas Industry: In the oil and gas sector, they are used in drilling equipment, wellhead assemblies, and downhole tools. They facilitate the transfer of signals, power, or fluids across barriers in high-pressure and high-temperature environments encountered during oil exploration and production operations.

Aerospace and Aviation: Aerospace applications often involve extreme conditions during space missions, aircraft operations, and rocket propulsion. High-pressure & high-temperature hermetic feedthroughs are utilized in spacecraft, satellites, aircraft engines, and avionics systems to maintain sealing integrity for sensors, instrumentation, and electrical connections.

Deep-Sea Exploration: In marine exploration and research, where equipment operates at significant depths under high-pressure and high-temperature conditions, these feedthroughs are used in underwater vehicles, submersibles, and oceanographic instrumentation. They enable reliable communication, data acquisition, and power distribution for sensors and equipment deployed in deep-sea environments.Industrial Processes: They find application in various industrial processes such as chemical processing, petrochemical refining, and high-temperature manufacturing. They are used in pressure vessels, reactors, furnaces, and industrial equipment to maintain sealing integrity for sensors, instrumentation, and electrical connections.

FAQ

Q:How do high-pressure & high-temperature hermetic feedthroughs work?

A:They feature robust construction and sealing mechanisms that prevent fluid or gas leakage across barriers exposed to extreme pressures and temperatures. They facilitate the transfer of signals, power, or fluids while maintaining a hermetic seal.

Q:What materials are used in them?

A:These feedthroughs are typically constructed from durable materials such as stainless steel, titanium, ceramics, and specialized alloys that can withstand high temperatures, corrosion, and mechanical stress encountered in extreme environments.

In conclusion

TJNE is a leading manufacturer and supplier of High-Pressure & High-Temperature Hermetic Feedthroughs, offering comprehensive technical expertise, certification reports, and reliable after-sales service. Contact yangbo@tjanode.com today to explore our range of feedthroughs tailored to your specific requirements.