- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

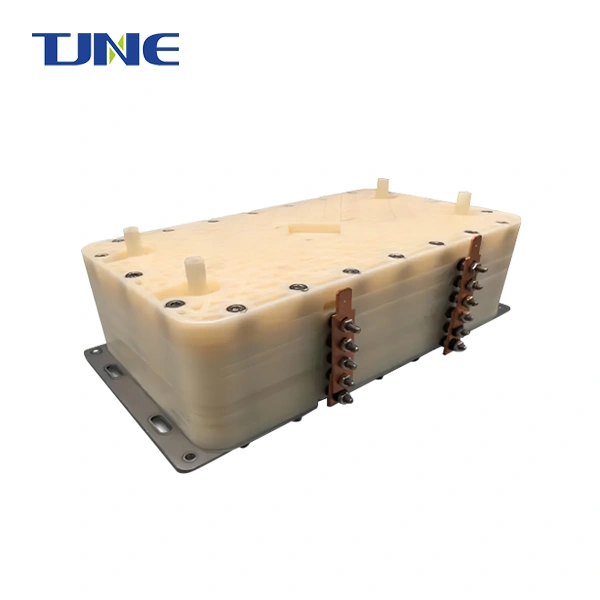

Chlorine Electrolysis Cell

2.Coating: Coated with ruthenium and iridium coatings, with a service life more than 5 years. Generation of effective chlorine concentration: ≥9000 ppm.

3.Coating thickness: 0.2-20μm, maintaining stable operation in seawater electrolysis. Chlorine precipitation anode life >5 years, cathode life >20 years.

4.Specification: Available in 50g/h, 100g/h, 200g/h, 300g/h, 1000g/h, 5000g/h and more.

5.Consumption: Salt consumption: ≤2.8 kg/ kg·Cl, DC power consumption: ≤3.5 kwh/kg·Cl.

6.Application: Animal husbandry disinfection, circulating water descaling, disinfection of drinking water, ship ballast water treatment, chemical manufacturing, and swimming pool disinfection.

The Chlorine Electrolysis Cell represents a significant advancement in technology, specifically engineered for the efficient generation of chlorine gas through a sophisticated electrolysis process. This cutting-edge device plays a pivotal role across multiple industries, including water treatment, chemical manufacturing, and food processing, where the demand for high-quality chlorine is essential. By delivering reliable and efficient chlorine production, the cell supports a variety of applications that are critical for maintaining hygiene, ensuring safe water supplies, and facilitating numerous chemical reactions.With the cell, industries can produce chlorine on-site, significantly reducing transportation costs and minimizing environmental impacts associated with chlorine handling and storage. Overall, this innovative device not only enhances production efficiency but also supports sustainable practices across diverse sectors.

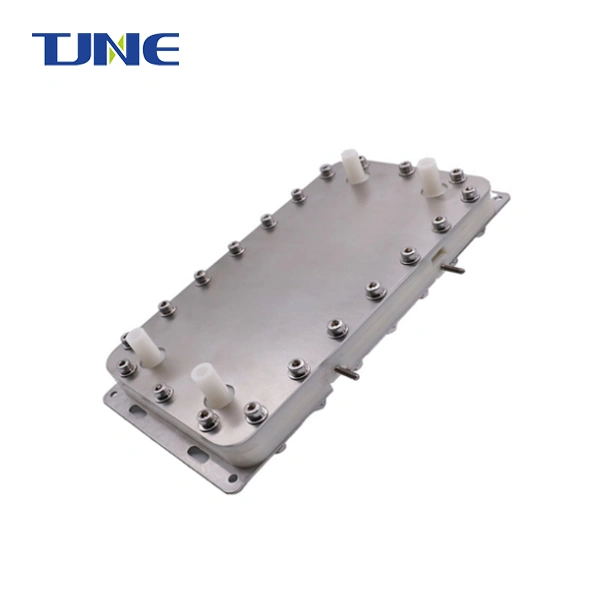

The Titanium Anode in Chlorine Electrolysis Cell utilizes a unique chemical composition and structure to ensure its stability and durability during electrochemical reactions. It has following advantages:

- High current density and efficiency

- Superior corrosion resistance

- Long service life

- Customizable shapes and coating options

- Wide operating pH range

- Cost-effective and energy-efficient

- Low maintenance requirements

The Chlorine Electrolysis Cell is a cutting-edge device designed for generating chlorine gas through an electrolysis process. It has a wide range of applications across various industries, delivering high-performance and efficient chlorine production.

The cell utilizes an electrochemical reaction to produce chlorine gas. It consists of an anode and a cathode separated by an electrolyte. When a direct electric current is passed through the electrolyte, chlorine gas is generated at the anode, while hydrogen gas is produced at the cathode. The chlorine gas can then be collected and used for various applications.

Working Principle

Low-concentration saltwater undergoes an electrochemical reaction through an electrified electrode to generate a sodium hypochlorite solution. After being electrified, H2O discharges on the cathode surface to generate OH - and H2, while Cl - discharges on the anode surface to generate Cl2, which then reacts with OH - to generate CLO -.

Electrode reaction: Anode: 2Cl --2e → Cl2

Cathode: 2H++2e → H2

Solution reaction: 2NaOH+Cl2 → NaCl+NaClO+H2O

The total reaction expression is as follows:

NaCl+H2O → NaClO+H2 ↑

Applications

The Chlorine Electrolysis Cell finds its applications in:

animal husbandry disinfection

circulating water descaling

disinfection of drinking water

ship ballast water treatment

chemical manufacturing

swimming pool disinfection

FAQ

What is the lifespan of the Chlorine Electrolysis Cell?

The cell is designed for a lifespan of 5 years under normal operating conditions.

What certifications does the product hold?

The Chlorine Electrolysis Cell is certified to meet international safety and quality standards such as ISO.

What after-sales services are provided?

TJNE offers comprehensive one-stop after-sales services, including technical support, maintenance, and spare parts supply.

If you are considering our Chlorine Electrolysis Cell, feel free to contact us at yangbo@tjanode.com. We are a professional manufacturer and supplier with strong technical expertise, fast delivery, and excellent customer support. We provide complete certification and testing reports to ensure the reliability of our products.