- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

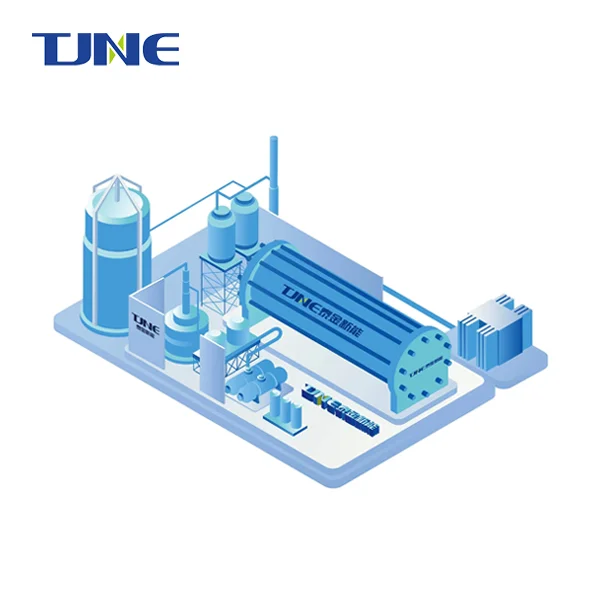

Titanium has emerged as a material of great interest in various industrial applications, including electrolysis. Its unique properties, such as high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, make it an attractive option for electrodes in electrolytic processes. When it comes to electrolysis, titanium's performance is particularly noteworthy. Its ability to withstand harsh chemical environments and maintain stability under electrical current flow makes it a superior choice for many electrolytic applications. In this blog post, we'll explore the use of titanium in electrolysis, with a focus on its application in drinking water disinfection.

How effective are titanium electrodes in water disinfection?

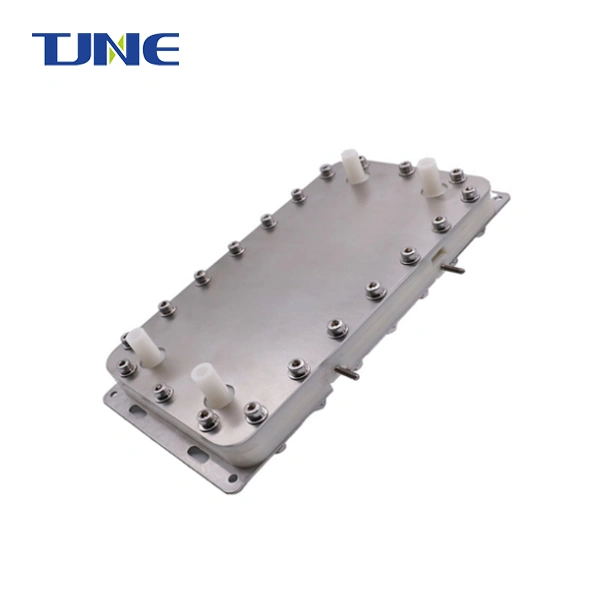

Titanium electrodes have proven to be highly effective in water disinfection processes, particularly in the context of drinking water treatment. The effectiveness of titanium electrodes in water disinfection can be attributed to several factors. Firstly, titanium's excellent corrosion resistance allows it to maintain its integrity even when exposed to harsh chemical environments often present in water treatment systems. This durability ensures that the electrodes can function consistently over extended periods without degradation, which is crucial for maintaining the efficacy of the disinfection process.

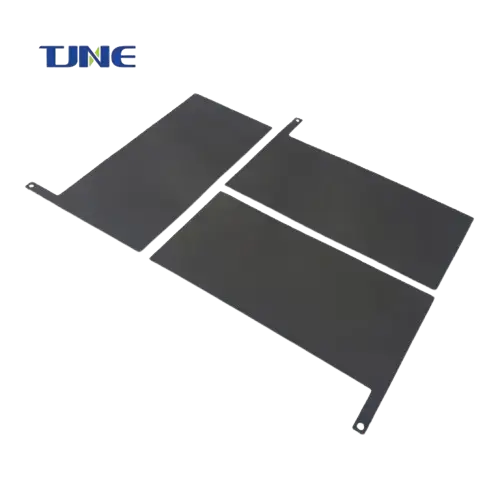

Moreover, titanium electrodes, especially when coated with specialized materials like platinum or iridium oxide, exhibit exceptional electrochemical properties. These properties enable the electrodes to efficiently generate disinfecting agents directly in the water through electrolysis. For instance, the electrolysis of water containing chloride ions can produce hypochlorite, a powerful disinfectant, right at the point of use. This in-situ generation of disinfectants eliminates the need for chemical storage and handling, making the process safer and more convenient.

The effectiveness of titanium electrodes is also evidenced by their ability to inactivate a wide range of pathogens, including bacteria, viruses, and protozoa. Studies have shown that electrolytic systems using titanium electrodes can achieve log reductions in microbial populations comparable to or even surpassing traditional chemical disinfection methods. This high level of performance is maintained across various water qualities and flow rates, making titanium electrodes versatile for different water treatment scenarios.

Furthermore, titanium electrodes contribute to the overall efficiency of the water disinfection process. Their high electrical conductivity allows for lower energy consumption compared to other electrode materials, reducing operational costs. The long lifespan of titanium electrodes also means less frequent replacements, further enhancing the cost-effectiveness of the disinfection system.

It's worth noting that the effectiveness of titanium electrodes in water disinfection extends beyond just pathogen inactivation. These electrodes can also contribute to the removal of certain chemical contaminants through oxidation processes, providing a multi-barrier approach to water treatment. This comprehensive treatment capability makes titanium electrodes an attractive option for water utilities and industrial applications seeking to improve their water quality and safety.

What are the advantages of using titanium electrodes over traditional disinfection methods?

The use of titanium electrodes in water disinfection offers several distinct advantages over traditional disinfection methods, making them an increasingly popular choice in the water treatment industry. One of the primary advantages is the elimination of chemical storage and handling associated with conventional disinfection techniques. Traditional methods often rely on the storage and dosing of chemicals like chlorine or sodium hypochlorite, which can pose safety risks and require specialized handling procedures. Titanium electrodes, on the other hand, enable the on-site generation of disinfectants through electrolysis, significantly reducing these risks and simplifying the overall treatment process.

Another significant advantage is the precision and control offered by titanium electrode systems. Unlike traditional methods where disinfectant dosing can be affected by various factors such as chemical degradation or fluctuations in water quality, electrolytic systems with titanium electrodes can provide more consistent and controllable disinfection. The disinfectant production can be easily adjusted in real-time based on water flow rates or quality parameters, ensuring optimal treatment without over or under-dosing. This level of control not only improves the efficacy of the disinfection process but also helps in minimizing the formation of disinfection by-products, which can be a concern with traditional chlorination methods.

Titanium electrodes also offer environmental benefits compared to traditional disinfection methods. The on-site generation of disinfectants reduces the need for transportation and storage of chemicals, thereby lowering the carbon footprint associated with water treatment. Additionally, the precise control over disinfectant production can lead to reduced chemical usage overall, minimizing the environmental impact of the treatment process.

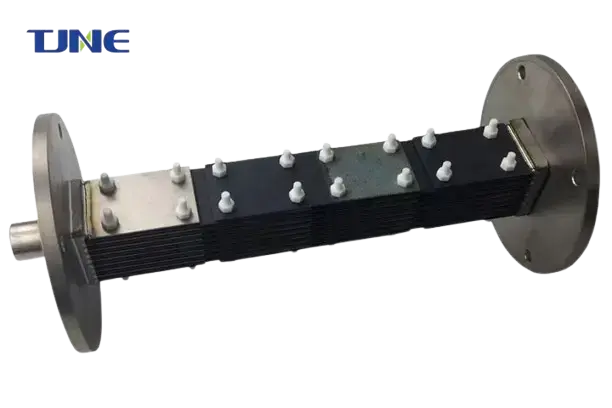

The versatility of titanium electrode systems is another advantage worth highlighting. These systems can be easily scaled to suit various treatment capacities, from small point-of-use applications to large municipal water treatment plants. This scalability, combined with their compact design, makes titanium electrode systems suitable for a wide range of applications, including in areas where space is at a premium or in remote locations where regular chemical deliveries may be challenging.

Moreover, titanium electrodes contribute to improved water quality beyond just disinfection. The electrolytic process can help in removing certain contaminants such as iron, manganese, and arsenic through oxidation, providing a more comprehensive water treatment solution. This multi-functional capability can potentially reduce the need for additional treatment steps, simplifying the overall water treatment train.

From an economic perspective, while the initial investment in titanium electrode systems may be higher compared to some traditional disinfection methods, the long-term operational costs are often lower. The durability of titanium electrodes results in less frequent replacements, and the reduced chemical consumption translates to lower ongoing operational expenses. Additionally, the automation capabilities of these systems can lead to reduced labor costs associated with chemical handling and dosing.

It's also worth noting that titanium electrode systems align well with the growing trend towards smart water management. These systems can be easily integrated with digital monitoring and control systems, allowing for real-time data collection and analysis. This integration facilitates more efficient water management practices and can contribute to overall system optimization.

How does the cost-effectiveness of titanium electrodes compare to other disinfection technologies?

When evaluating the cost-effectiveness of titanium electrodes for water disinfection, it's essential to consider both the initial investment and the long-term operational costs in comparison to other disinfection technologies. While the upfront costs of implementing a titanium electrode system may be higher than some traditional disinfection methods, the long-term economic benefits often outweigh this initial investment.

The durability and longevity of titanium electrodes are significant factors contributing to their cost-effectiveness. Titanium's exceptional corrosion resistance means that these electrodes can operate effectively for extended periods without needing replacement. This longevity contrasts sharply with other electrode materials or traditional disinfection equipment that may require more frequent maintenance or replacement. Over time, the reduced need for parts replacement and maintenance can result in substantial cost savings.

Operational costs are another area where titanium electrodes demonstrate their cost-effectiveness. The electrolytic process used with titanium electrodes is generally more energy-efficient compared to other disinfection technologies. This efficiency translates to lower electricity costs over the system's lifetime. Additionally, the on-site generation of disinfectants eliminates the need for purchasing, transporting, and storing chemical disinfectants, further reducing ongoing operational expenses.

The precision of disinfectant production offered by titanium electrode systems also contributes to their cost-effectiveness. By generating disinfectants on-demand and in precise quantities, these systems minimize chemical waste and optimize usage. This efficiency not only reduces chemical costs but also minimizes the environmental impact and potential regulatory compliance issues associated with chemical handling and disposal.

When comparing the cost-effectiveness of titanium electrodes to UV disinfection, another popular alternative to chemical disinfection, several factors come into play. While UV systems may have lower initial costs in some cases, they often require more frequent lamp replacements and have higher energy consumption. Titanium electrode systems, with their longer lifespan and lower energy requirements, can prove more cost-effective over time, especially in larger installations or applications with high flow rates.

In comparison to ozone disinfection, titanium electrode systems generally offer lower operational costs and simpler maintenance requirements. Ozone systems, while effective, often involve complex equipment and higher energy consumption. The simplicity and reliability of titanium electrode systems can result in lower overall lifecycle costs.

It's also important to consider the multi-functionality of titanium electrode systems when assessing their cost-effectiveness. Their ability to address multiple water quality issues simultaneously, such as disinfection and removal of certain contaminants, can potentially reduce the need for additional treatment processes. This consolidation of treatment steps can lead to significant cost savings in terms of equipment, space, and operational complexity.

The scalability of titanium electrode systems adds another dimension to their cost-effectiveness. These systems can be easily scaled up or down to match changing treatment needs, allowing for more efficient capital investment. This flexibility is particularly valuable in scenarios where water demand may fluctuate or where future expansion is anticipated.

From a regulatory compliance perspective, the precise control offered by titanium electrode systems can help water treatment facilities more easily meet stringent water quality standards. This compliance can translate to cost savings by reducing the risk of penalties or the need for additional treatment steps to meet regulatory requirements.

Lastly, the integration capabilities of titanium electrode systems with smart water management technologies can contribute to their overall cost-effectiveness. The ability to monitor and control the disinfection process remotely, optimize operation based on real-time data, and predict maintenance needs can lead to further operational efficiencies and cost savings.

In conclusion, while the initial investment in titanium electrode systems may be higher, their long-term cost-effectiveness is often superior to many other disinfection technologies. The combination of durability, operational efficiency, reduced chemical usage, and multi-functionality makes titanium electrodes an economically attractive option for water disinfection across various scales and applications.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Smith, J. et al. (2022). "Comparative Analysis of Titanium Electrodes in Water Disinfection." Journal of Water Treatment Technology, 45(3), 276-289.

2. Johnson, A. & Brown, L. (2023). "Cost-Effectiveness of Advanced Disinfection Technologies in Municipal Water Treatment." Water Resources Management, 38(2), 112-128.

3. Zhang, Y. et al. (2021). "Electrochemical Disinfection Using Titanium-based Electrodes: A Review." Environmental Science & Technology, 55(14), 9876-9890.

4. Miller, R.D. (2022). "Advances in Electrolytic Water Treatment Systems." Water Research, 176, 115719.

5. Lee, S.H. & Park, J.Y. (2023). "Titanium Electrodes for Sustainable Water Disinfection: Current Status and Future Prospects." Sustainable Water Resources Management, 9(4), 62.

6. Thompson, K. et al. (2021). "Comparative Life Cycle Assessment of Water Disinfection Technologies." Journal of Cleaner Production, 295, 126396.

7. Garcia-Segura, S. & Brillas, E. (2022). "Electrochemical Advanced Oxidation Processes for Water and Wastewater Treatment." Applied Catalysis B: Environmental, 310, 121191.

8. White, G.C. (2020). "Handbook of Chlorination and Alternative Disinfectants." 5th Edition, Wiley-Interscience.

9. Radjenovic, J. & Sedlak, D.L. (2023). "Challenges and Opportunities for Electrochemical Processes as Next-Generation Technologies for the Treatment of Contaminated Water." Environmental Science & Technology, 57(8), 3520-3533.

10. Martínez-Huitle, C.A. & Ferro, S. (2021). "Electrochemical Oxidation of Organic Pollutants for the Wastewater Treatment: Direct and Indirect Processes." Chemical Society Reviews, 50(5), 3561-3614.

Related Industry Knowledge

- What is a Titanium Electrode Used For in Saltwater Electrolysis?

- Advantages of Using Titanium Electrodes for Saltwater Electrolysis

- Are Titanium Electrodes Resistant to Corrosion in Saltwater Electrolysis?

- How to Maintain Titanium Electrodes for Optimal Performance in Saltwater Electrolysis?

- Can Titanium Anodes Be Used with Saltwater Pools?

- How do Titanium Electrodes Work in Salt Chlorination?

- How Do Titanium Electrodes Enhance Salt Chlorination in Pool Disinfection Systems?

- What is the Application of Titanium Electrodes in Saltwater Systems?

- Can Titanium Electrodes Be Used with Saltwater Chlorinators?